Device and method for measuring laser irradiation optical thin film damage threshold in high-temperature environment

A technology of laser irradiation and damage threshold, which is applied in measuring devices, scientific instruments, weather resistance/light resistance/corrosion resistance, etc., can solve the problem of not being able to obtain high temperature laser damage threshold, and achieve the effect of simple and easy measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

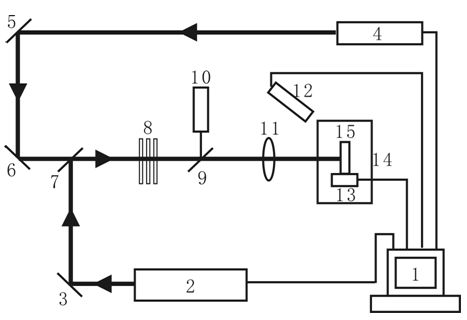

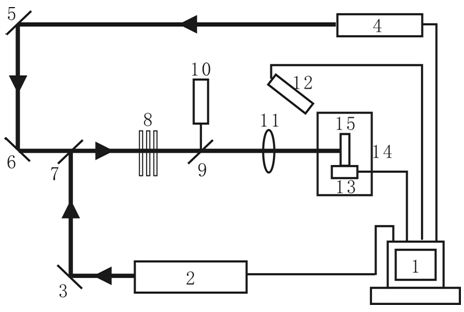

[0020] Example 1: In figure 1 Among them, the measuring device includes: computer 1, first laser 2, mirror 3, second laser 4, first mirror 5, second mirror 6, third mirror 7, energy attenuator 8, beam splitter 9 , Energy meter 10, focusing lens 11, online microscope judgment device 12, high temperature resistant movable platform 13 and temperature control box 14;

[0021] The output end of the computer 1 is connected with the first laser 2, the second laser 4, the online microscope judgment device 12 and the high temperature resistant movable platform 13; the first mirror 5, the second mirror 6, the third mirror 7, the energy attenuation The device 8, the beam splitter 9, and the focusing lens 11 are on the second optical path of the second laser 4. The first reflecting mirror 5 and the second reflecting mirror 6 in the second optical path are refracting mirrors, and the third reflecting mirror 7, the beam splitting mirror 9 and the focusing lens 11 are transmission mirrors; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com