Heavy load tire matrix durability evaluating method

An evaluation method and bead technology, which can be used in the direction of testing wear resistance, automobile tire testing, etc., and can solve the problems of tire puncture, cord breakage, and reduction of the strong force of the carcass cord.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

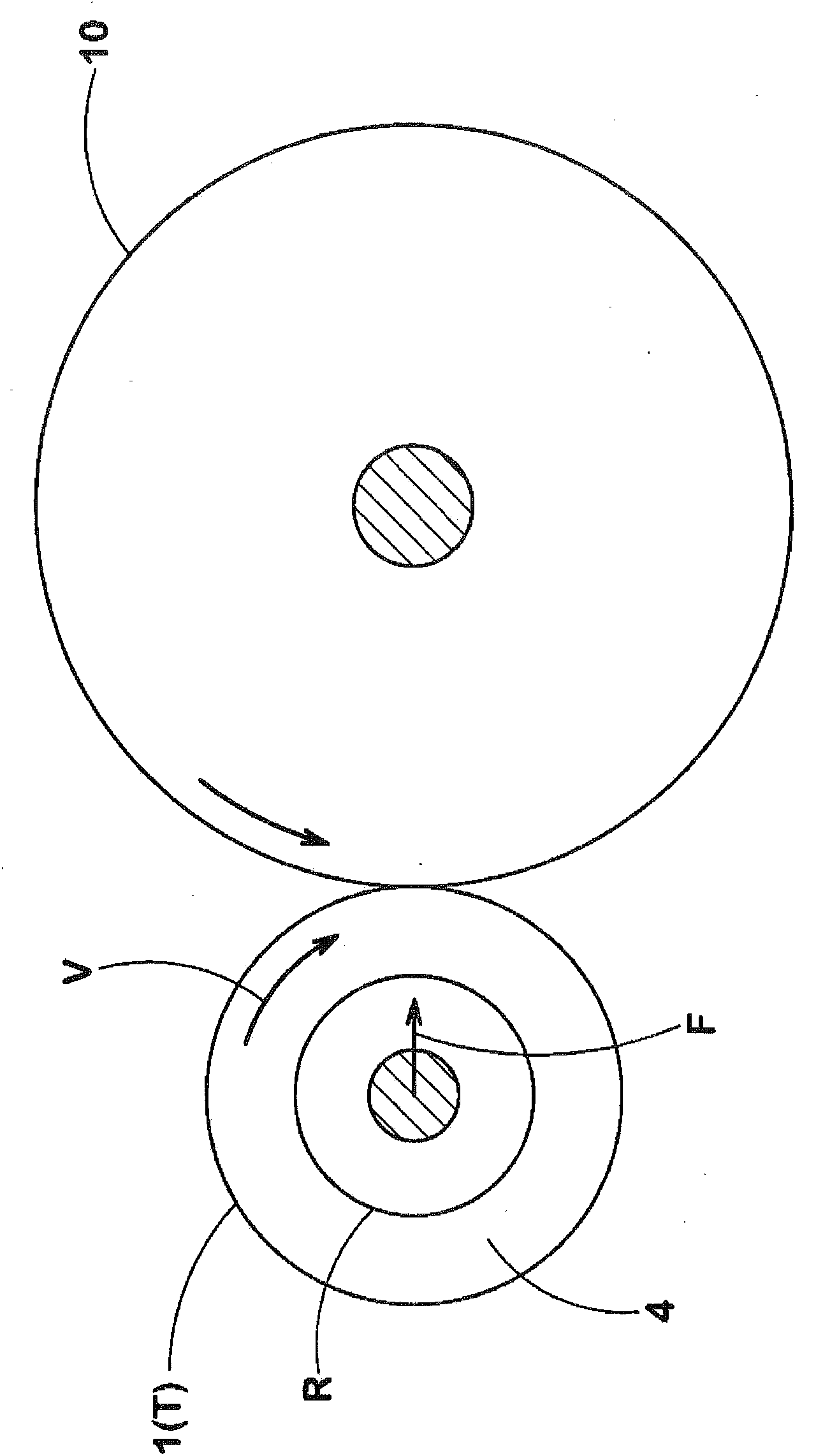

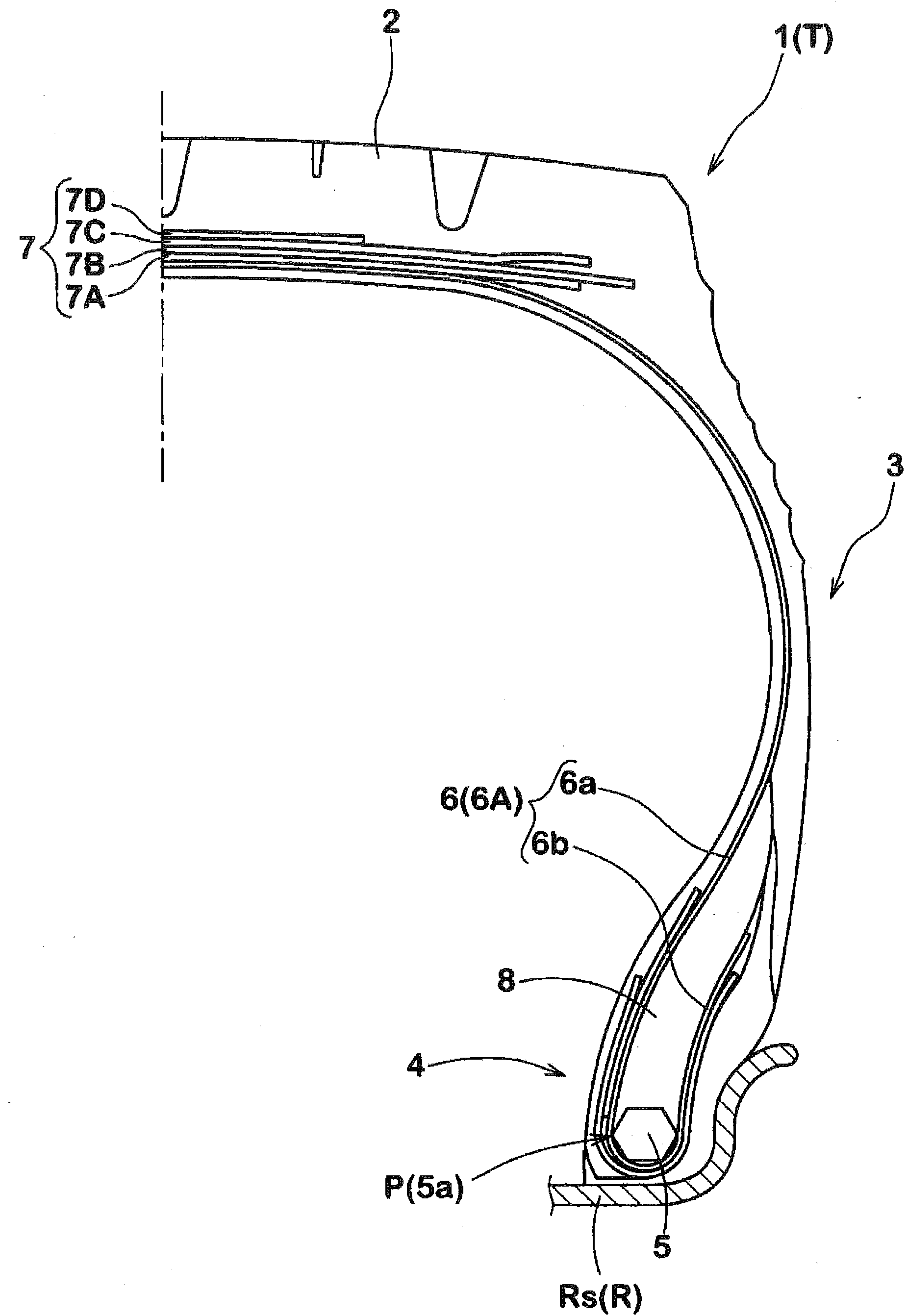

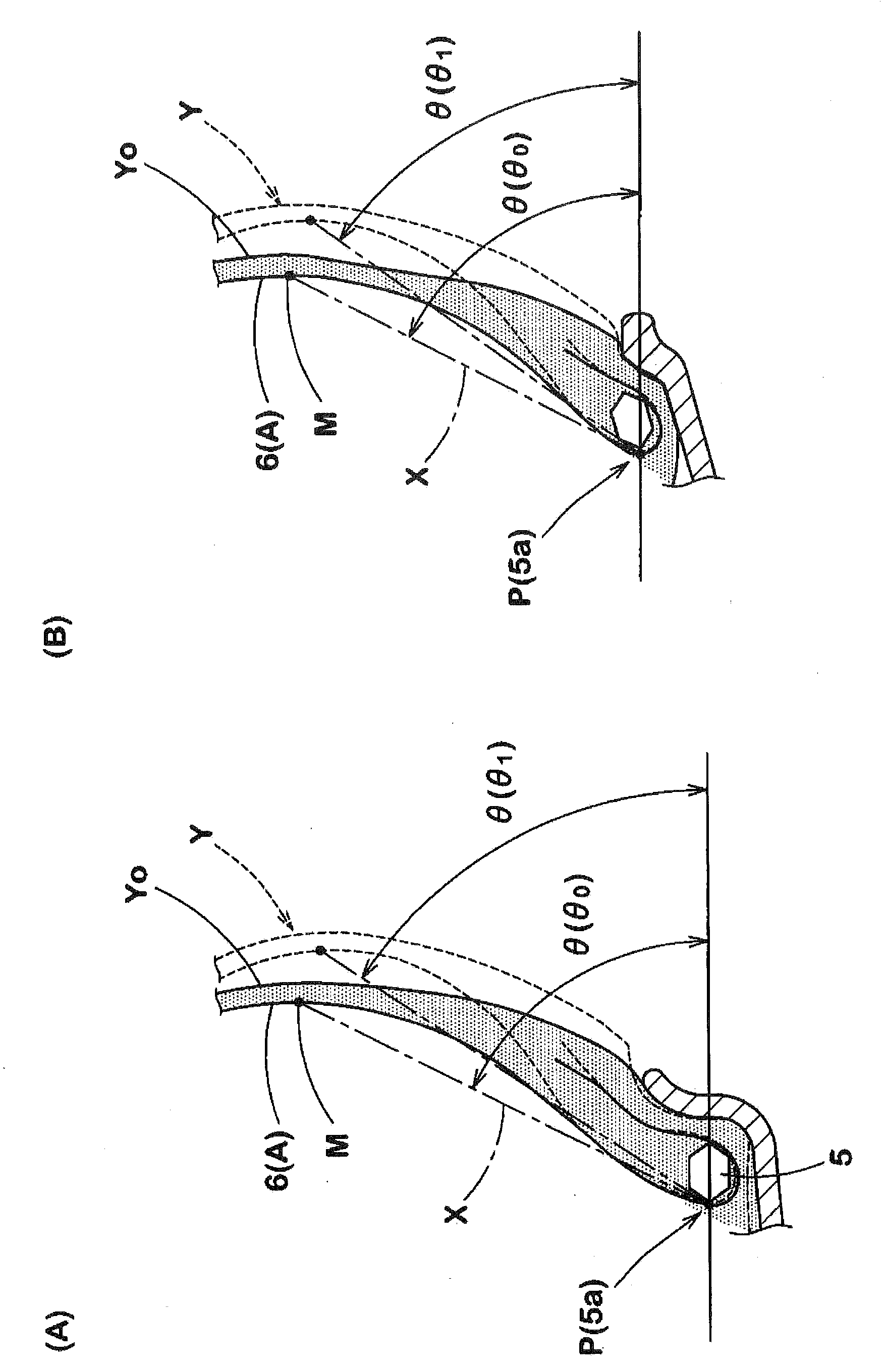

[0072] In order to confirm the effect of the present invention, the figure 2 A commercially available heavy-duty tire (12.00R20-16PR) having the structure shown was used as a test tire, and an evaluation test of carcass durability was performed under the criteria shown in Table 1. In addition, the test was performed on 10 tires under each condition, and the average value of the fretting wear amount and the deviation σ of the fretting wear amount were compared.

[0073] The normal internal pressure P0 of the test tire is 7.25kPa, and the normal load F 0 is 30.5kN. The amount of fretting wear is the wear volume of the worn part of the carcass cord at the innermost point in the tire axial direction of the bead core measured with a laser microscope, and the average value of the amount of fretting wear in Comparative Example 1 is taken as 100. index to represent its mean. The larger the value, the faster the abrasion progresses.

[0074] Table 1:

[0075]

[0076]

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com