High-temperature broadband wave-absorbing Al2O3f reinforced ceramic-based composite material and integrated preparation method

A composite material, al2o3f technology, applied in the direction of shielding materials, magnetic field/electric field shielding, electrical components, etc., can solve problems such as impedance mismatch and wave-absorbing performance degradation, influence of composite material mechanical properties, continuous fiber damage, etc., to achieve the production cycle Short, simple design and molding method, strong designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

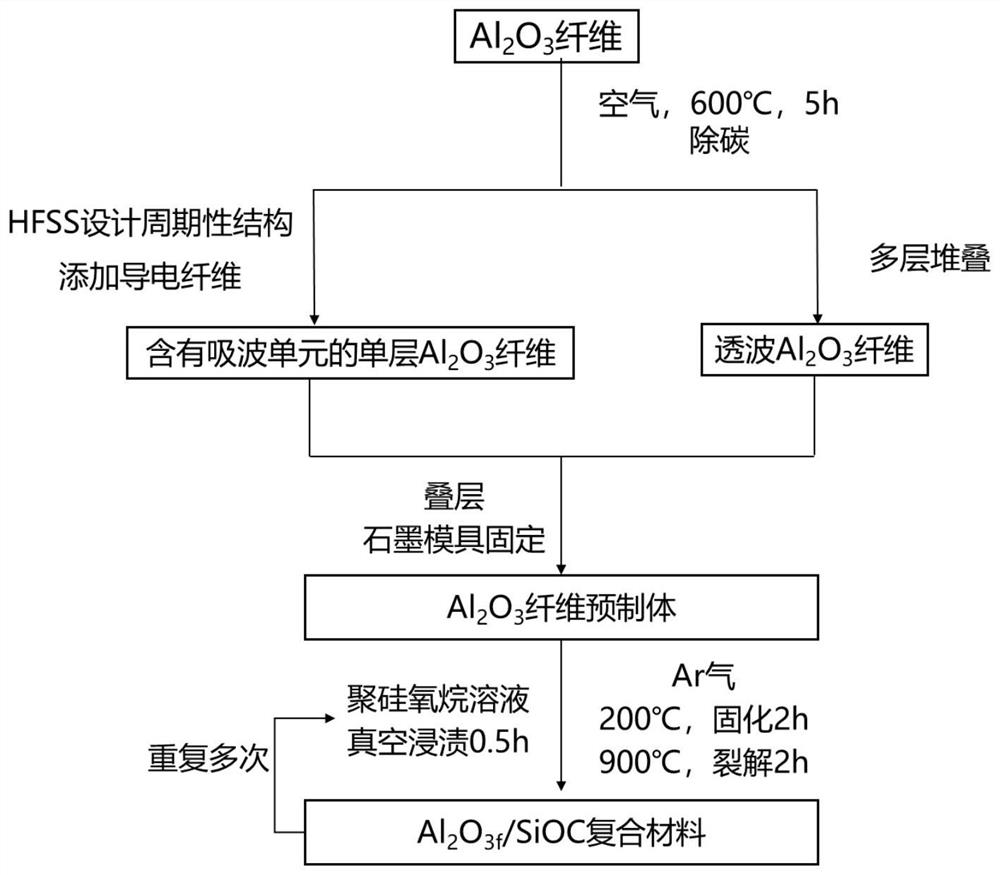

[0030] (1) Al 2 o 3 Put the fiber cloth into a box furnace and heat-treat it in the air at 600°C-700°C for 5h-6h to remove the sizing agent on the fiber surface;

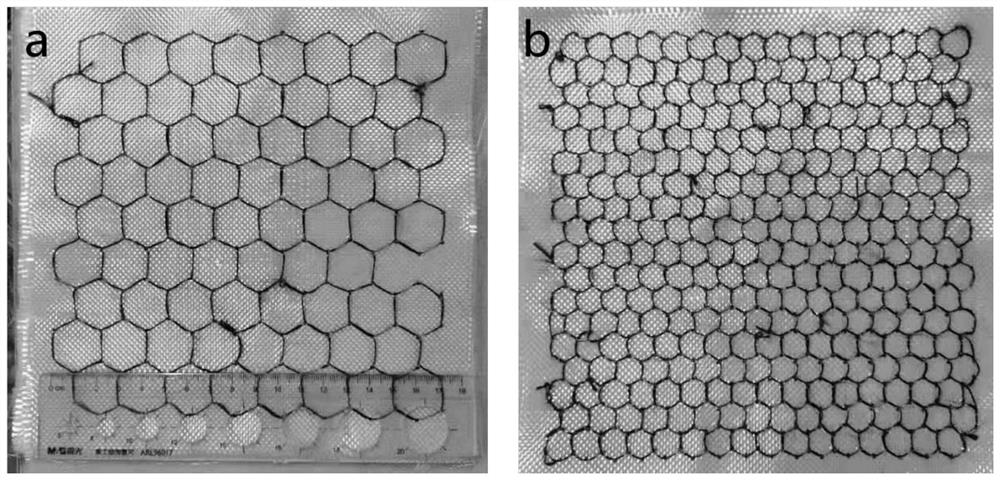

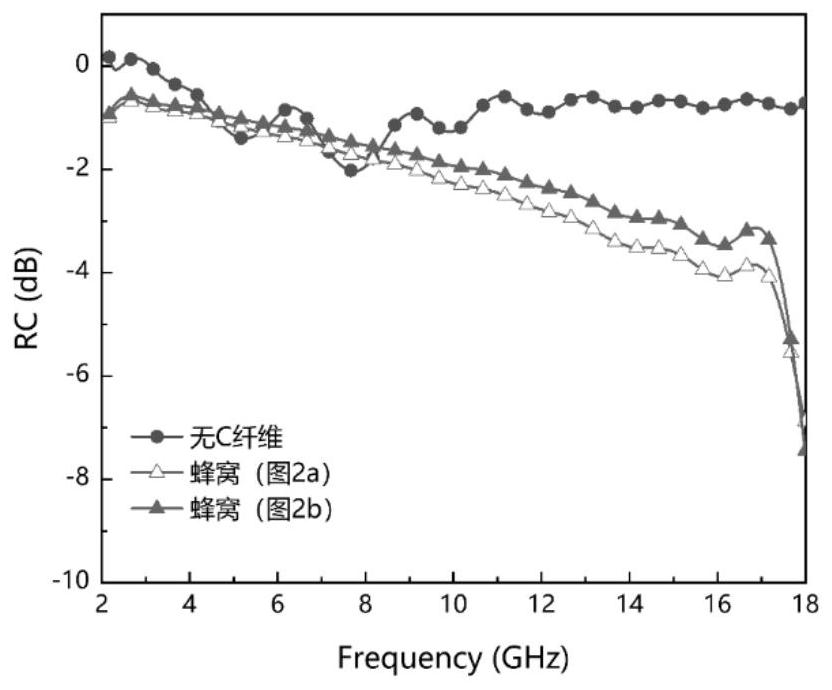

[0031] (2) the monolayer Al 2 o 3 The fiber cloth is cut into a size of 200mm×200mm, according to figure 2 The size of the honeycomb absorbing unit of a is to sew the C fiber on the single layer of Al 2 o 3 On the fiber cloth, the conductivity of the C fiber is about 10 5 S / m;

[0032] (3) Al in step 2 2 o 3 5 layers of wave-transparent Al are placed on the top and bottom of the fiber cloth 2 o 3 Fiber cloth, stacked into a sandwich structure, and fixed with graphite abrasives to obtain Al 2 o 3 fiber preform;

[0033] (4) the above Al 2 o 3 After the fiber preform was vacuum impregnated in the polysiloxane precursor solution for 0.5h, it was cracked at 900°C for 2h under the protection of an inert atmosphere (argon or nitrogen) to prepare the SiOC matrix, and a broadband absorbing Al 2 o 3f / SiOC co...

Embodiment 2

[0036] (1) Al 2 o 3 Put the fiber cloth into a box furnace and heat-treat it in the air at 600°C-700°C for 5h-6h to remove the sizing agent on the fiber surface;

[0037] (2) the monolayer Al 2 o 3 The fiber cloth is cut into a size of 200mm×200mm, according to figure 2 The size of the honeycomb absorbing unit of a is to sew the C fiber on the single layer of Al 2 o 3 On the fiber cloth, the conductivity of the C fiber is about 10 5 S / m;

[0038] (3) Al with absorbing unit in step 2 2 o 3 The fiber cloth is placed on the top layer, and 10 layers of wave-transparent Al are stacked underneath 2 o 3 fiber cloth, and fixed with graphite abrasives to obtain Al 2 o 3 fiber preform;

[0039] (4) the above Al 2 o 3 After the fiber preform was vacuum impregnated in the polysiloxane precursor solution for 0.5h, it was cracked at 900°C for 2h under the protection of an inert atmosphere (argon or nitrogen) to prepare the SiOC matrix, and a broadband absorbing Al 2 o 3f / ...

Embodiment 3

[0042] (1) Al 2 o 3 Put the fiber cloth into a box furnace and heat-treat it in the air at 600°C-700°C for 5h-6h to remove the sizing agent on the fiber surface;

[0043] (2) the monolayer Al 2 o 3 The fiber cloth is cut into a size of 200mm×200mm, according to figure 2 The size of the honeycomb absorbing unit of b is to sew the C fiber on the single layer of Al 2 o 3 On the fiber cloth, the conductivity of the C fiber is about 10 5 S / m;

[0044] (3) Al in step 2 2 o 3 5 layers of wave-transparent Al are placed on the top and bottom of the fiber cloth 2 o 3 Fiber cloth, stacked into a sandwich structure, and fixed with graphite abrasives to obtain Al 2 o 3 fiber preform;

[0045] (4) the above Al 2 o 3 After the fiber preform was vacuum impregnated in the polysiloxane precursor solution for 0.5h, it was cracked at 900°C for 2h under the protection of an inert atmosphere (argon or nitrogen) to prepare the SiOC matrix, and a broadband absorbing Al 2 o 3f / SiOC ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Reflection coefficient | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com