Eight-drive traveling type sandstone machine

A technology of sandstone and trolley, which is applied in open-pit mining, earth drilling, special mining, etc. It can solve the problems of complex structure, cumbersome operation, high performance requirements, etc., and achieve the effect of reasonable design, simple operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

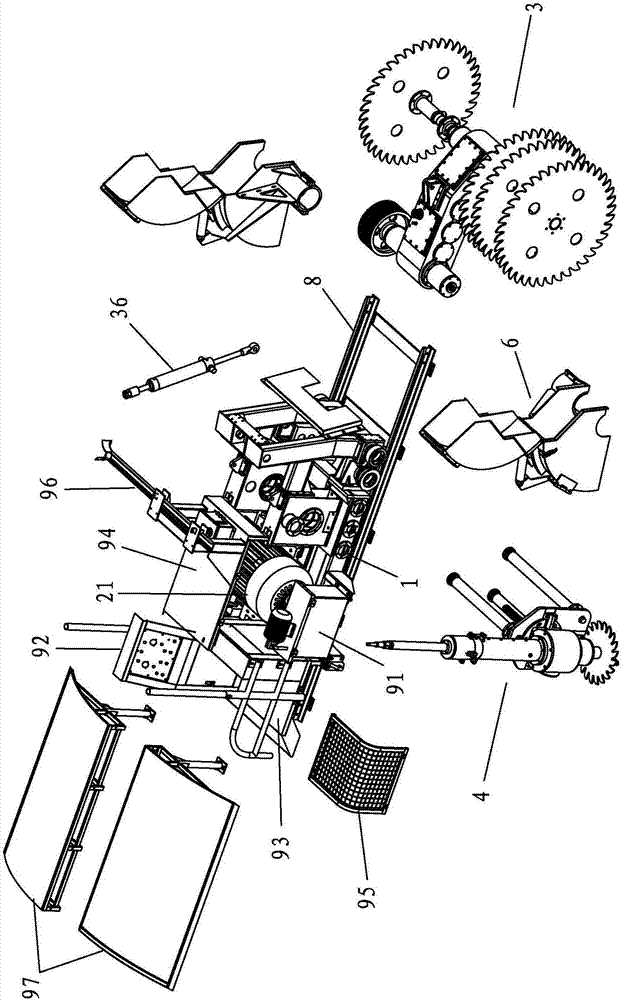

[0086] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

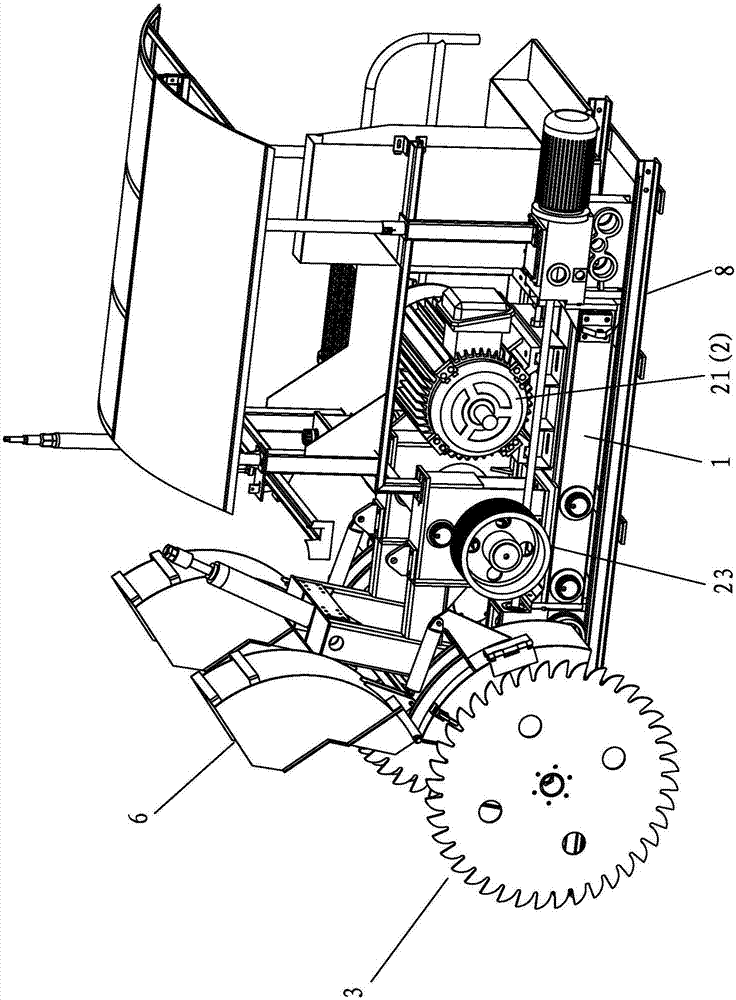

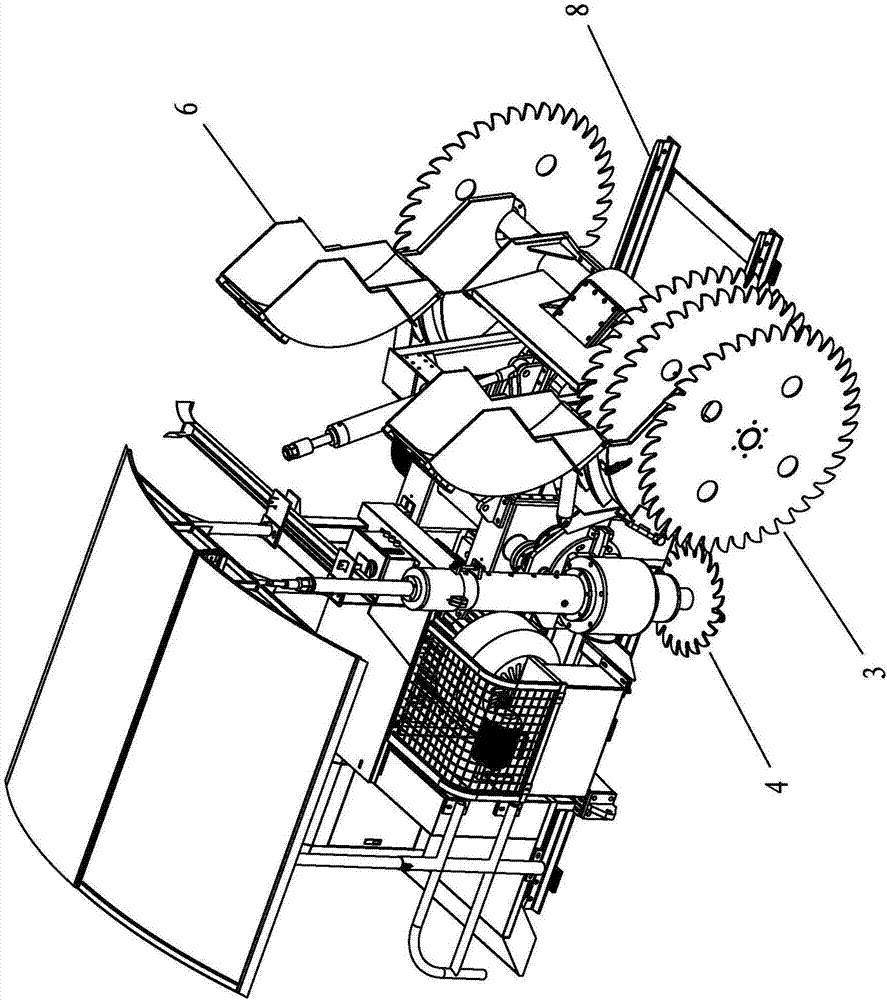

[0087] This case involves an eight-drive walking sandstone machine, such as Figure 1-5 As shown, it mainly includes a trolley 1, and a total drive assembly 2, a slitting assembly 3 and a cross-cutting assembly 4 arranged on the trolley 1.

[0088] The total drive assembly 2 mainly includes a power source 21 and an input shaft 22 which are in transmission connection with each other. One embodiment of the transmission connection is a belt transmission method. The input shaft 22 is provided with a large pulley 23, and the output shaft of the power source 21 is connected to the large pulley 23 through a belt (not shown). The trolley 1 is provided with an underframe 11, the underframe 11 is provided with a motor base, and the power source 21 is fixedly installed on the motor base. The base frame 11 is provided with two left and right swing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com