Method and device for detecting optical element laser damage threshold

A technology of laser damage threshold and optical components, which is applied in measuring devices, fluorescence/phosphorescence, and material analysis through optical means, and can solve problems such as inability to directly observe the morphology of the irradiated area online and unspecified discrimination methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

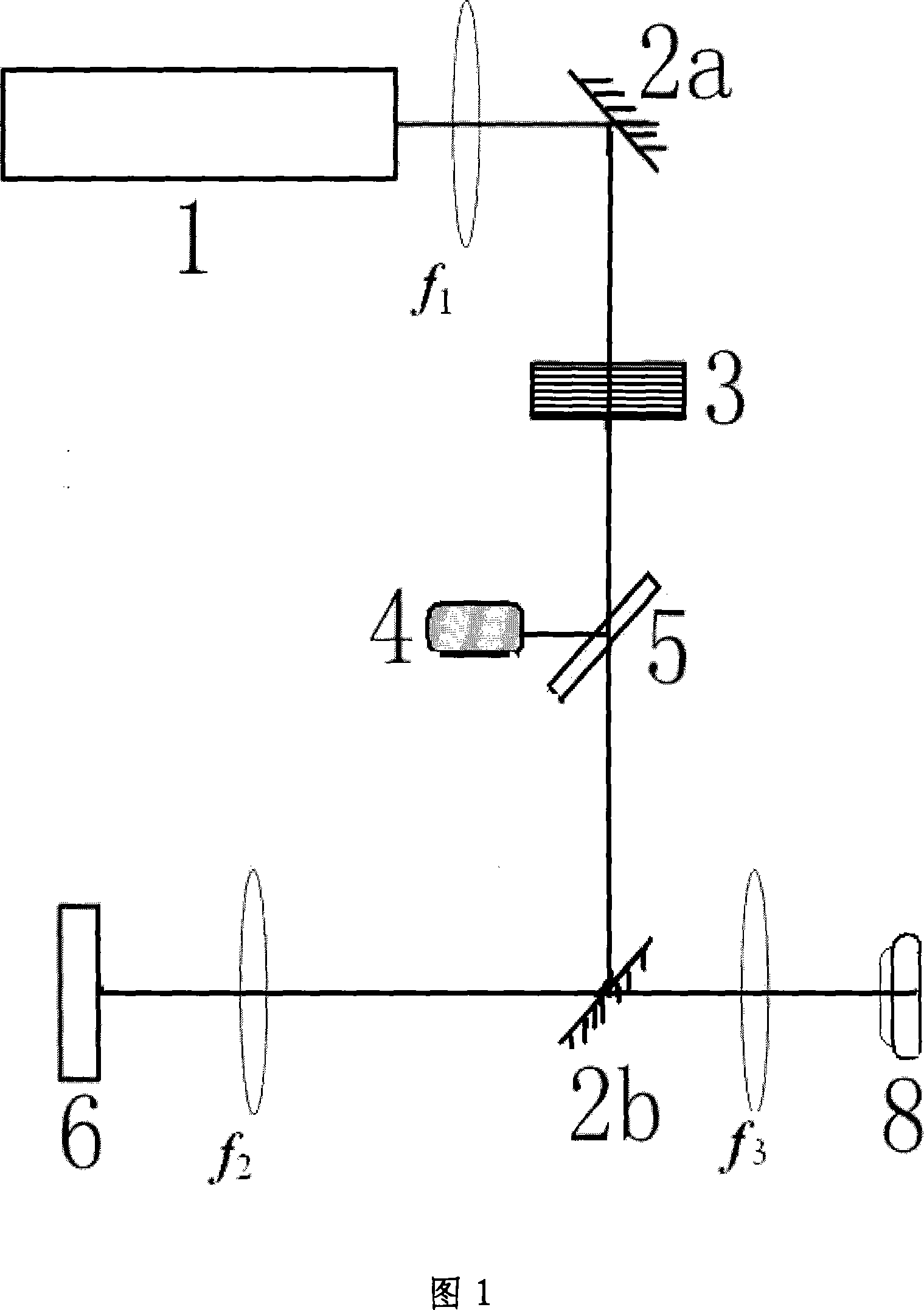

[0013] Below in conjunction with accompanying drawing, the present invention will be further described.

[0014] Implementation column 1:

[0015] As shown in Figure 1, the KrF laser (1) emits laser light with a pulse width of 24 ns, uniformly irradiates the area with a diameter of 2 mm on the surface of the optical element to be tested (6) at an incident angle of 0°, and the lens group f 1 , f 2 The uniformly distributed cross-sectional image of the beam is transmitted to the front surface of the optical element (6) to be tested, and the laser light excites the fluorescent spot on the surface of the intact optical element, and passes through the lens f 2 , f 3 The composed fluorescence microscope is magnified by 3 times and imaged on the CCD array detector (8), so as to observe the change of the surface of the optical element (6) to be tested, and judge whether the optical element (6) to be tested is damaged. The laser energy output by the KrF laser (1) is attenuated by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com