Automobile shock absorber performance test bench

A shock absorber and test bench technology, which is applied in the direction of vehicle suspension/shock absorbing mechanism testing, etc., can solve the problems of not being suitable for online production, difficult maintenance, large floor space, etc., and achieve compact structure, short time for changing varieties, and The effect of speed control stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

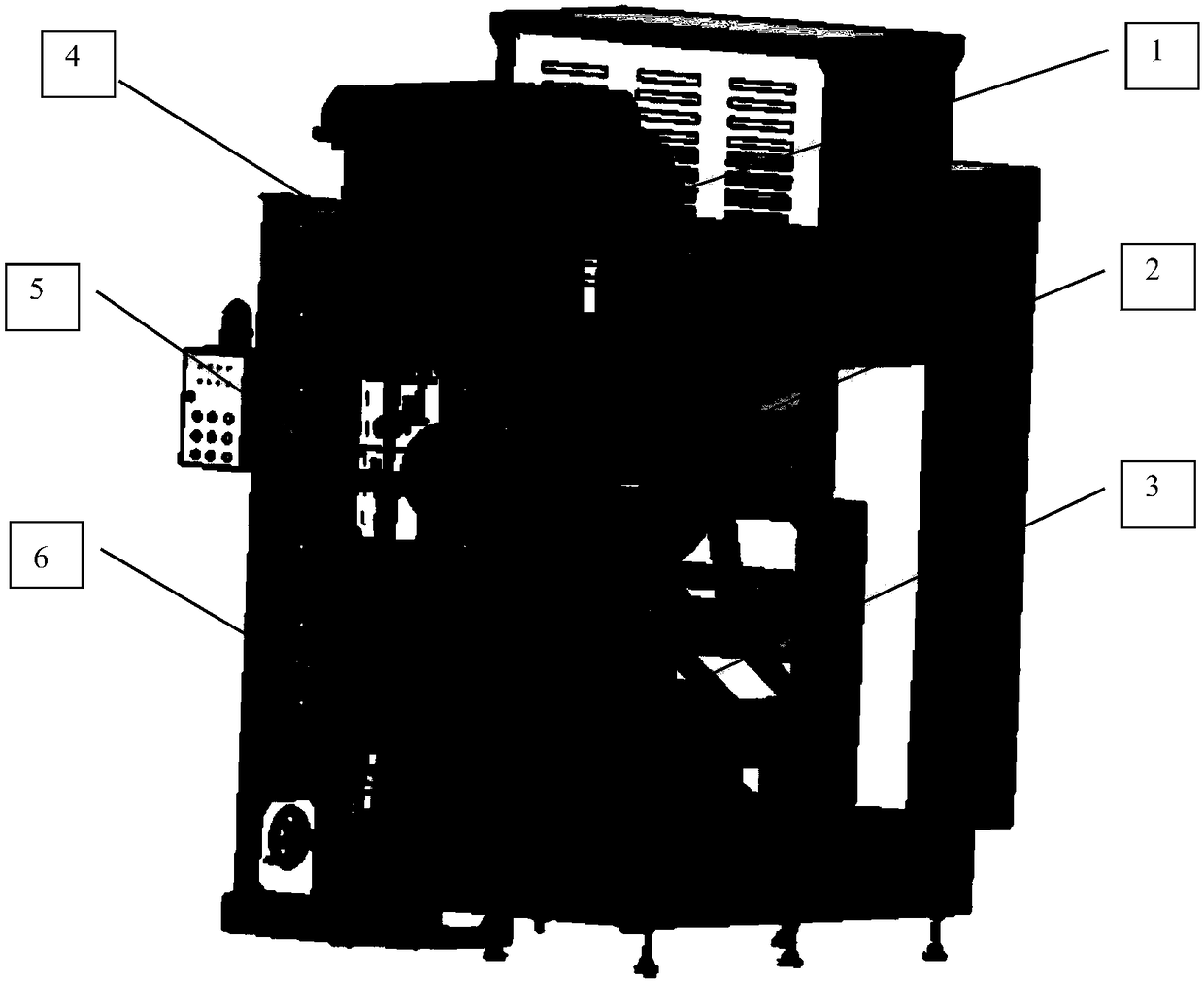

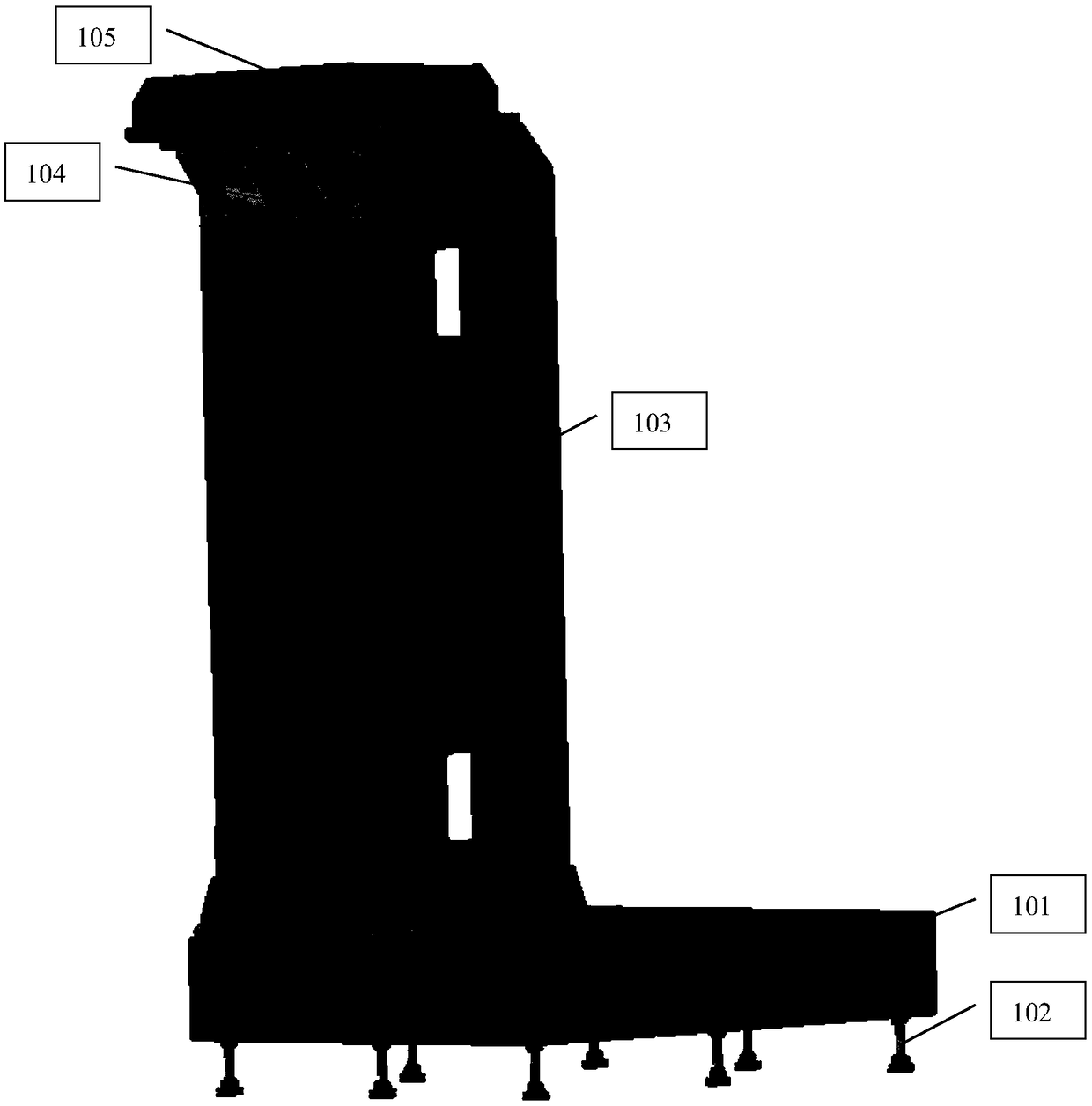

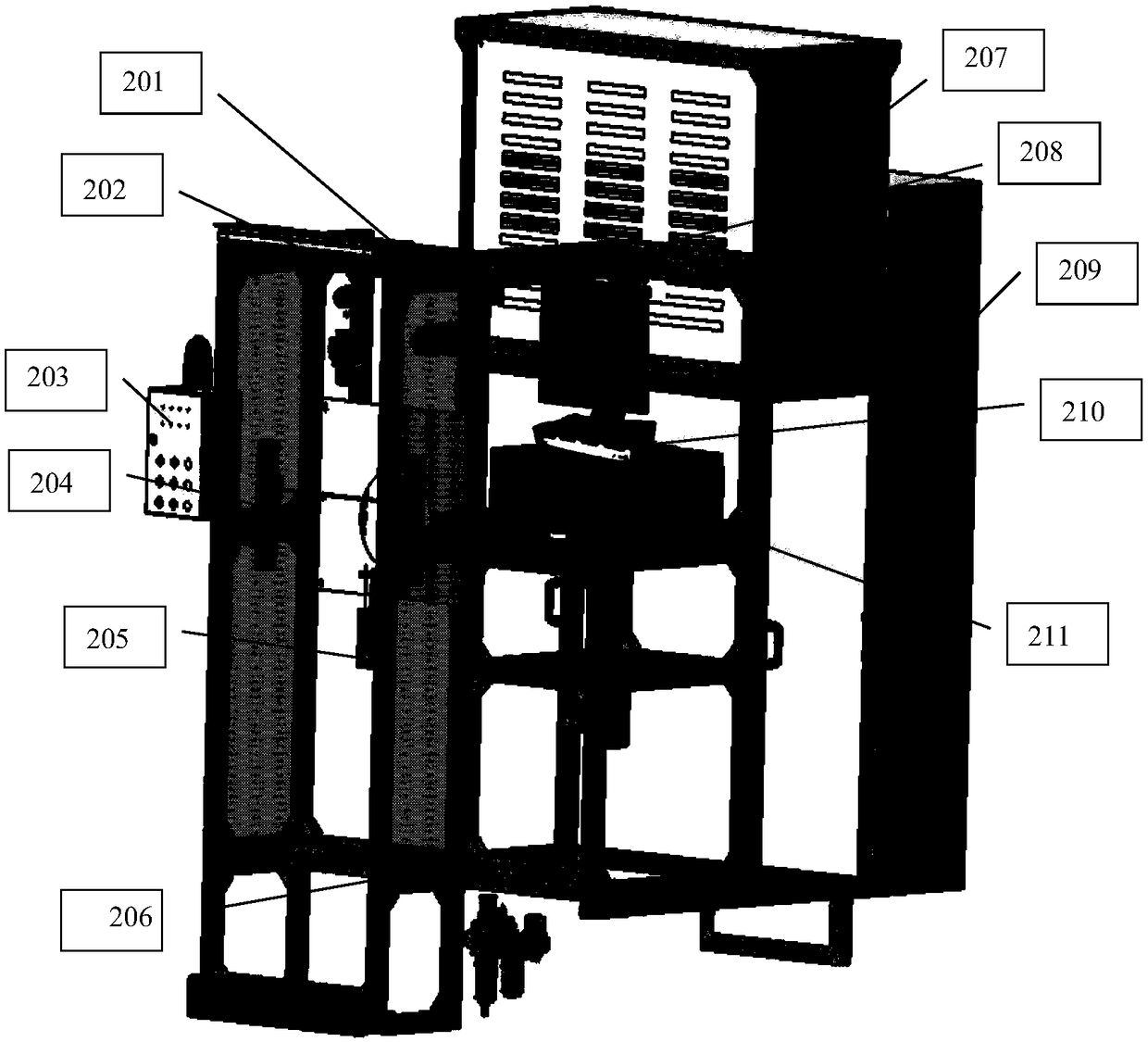

[0014] 1. Refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 , a kind of automobile shock absorber performance testing test bench according to the specific embodiment, its composition includes: bed 1, protection and control system 2, power and transmission system 3, upper transmission and force measuring mechanism 4, crank connecting rod and workpiece The clamping adjustment mechanism 5 and the fixture 6; wherein the protection and control system 2, the power and transmission system 3, the upper transmission and force measuring mechanism 4 are connected to the bed 1 through screws; the crank connecting rod and the workpiece clamping adjustment mechanism 5 are connected through The bearing is connected to the transmission shaft of the power and transmission system 3; the fixture 6 is connected to the crank connecting rod and the workpiece clamping adjustment mechanism 5 through the clamping positioning block.

[0015] 2. Refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com