Method and apparatus for online test of laser damages of optical element

A technology for optical components and on-line testing, applied in measurement devices, fluorescence/phosphorescence, material analysis through optical means, etc., can solve the problem of difficult accurate positioning of damage morphology, lack of intuition and continuity, and in-depth study of damage evolution of optical components and lack of mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

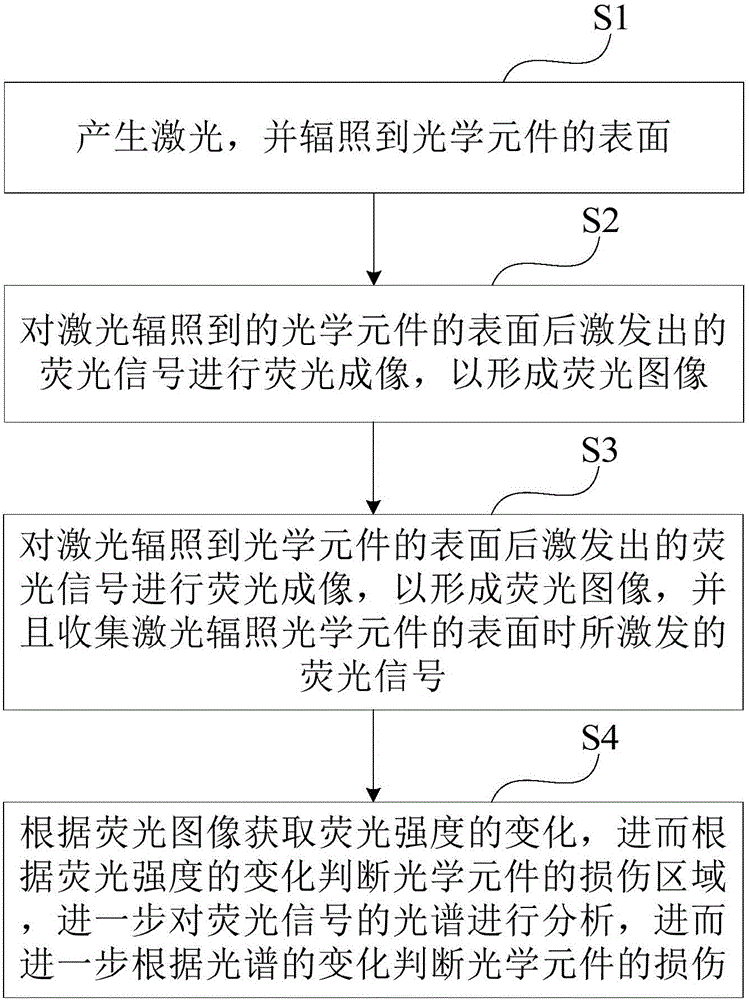

[0022] see figure 1 , figure 1 It is a flow chart of an online method for testing laser damage of an optical element provided by an embodiment of the present invention. like figure 1 As shown, the method of the present embodiment includes the following steps:

[0023] Step S1: Generate laser light and irradiate the surface of the optical element.

[0024] Step S2: performing fluorescence imaging on the fluorescence signal excited after the laser irradiates the surface of the optical element to form a fluorescence image.

[0025] Step S3: performing fluorescence imaging on the fluorescence signals excited after the laser irradiates the surface of the optical element to form a fluorescence image, and collecting the fluorescence signals excited when the laser irradiates the surface of the optical element.

[0026] Step S4: Obtain the change of the fluorescence intensity according to the fluorescence image, and then judge the damage area of the optical element according to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com