Combined testing device and testing method of laser damage thresholds of film and optical element

A technology of laser damage threshold and optical components, which is applied in the direction of optical testing of flaws/defects, testing of optical properties, measurement of scattering characteristics, etc. It can solve problems such as large errors in test results, poor practicability, and misjudgment of the adaptability of various thin film materials. , to achieve the effect of extreme error and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

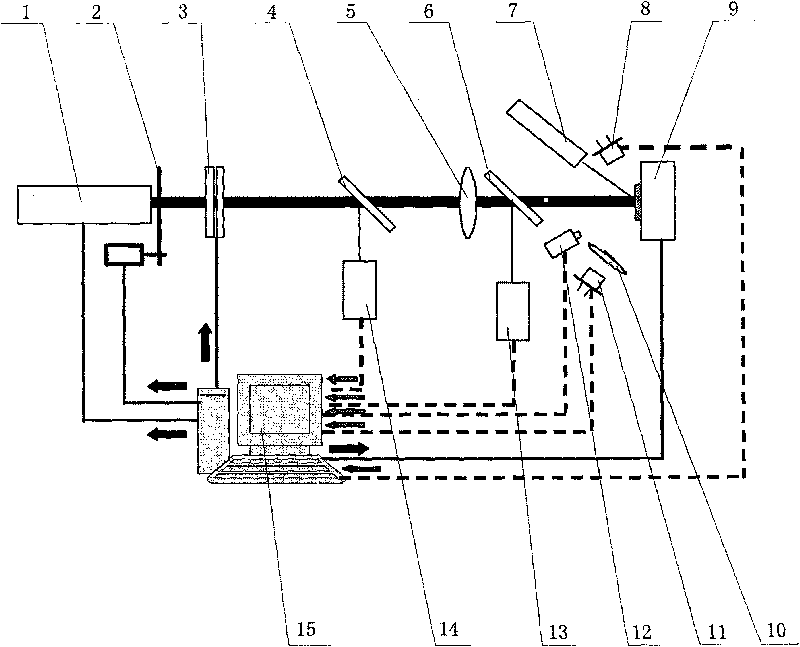

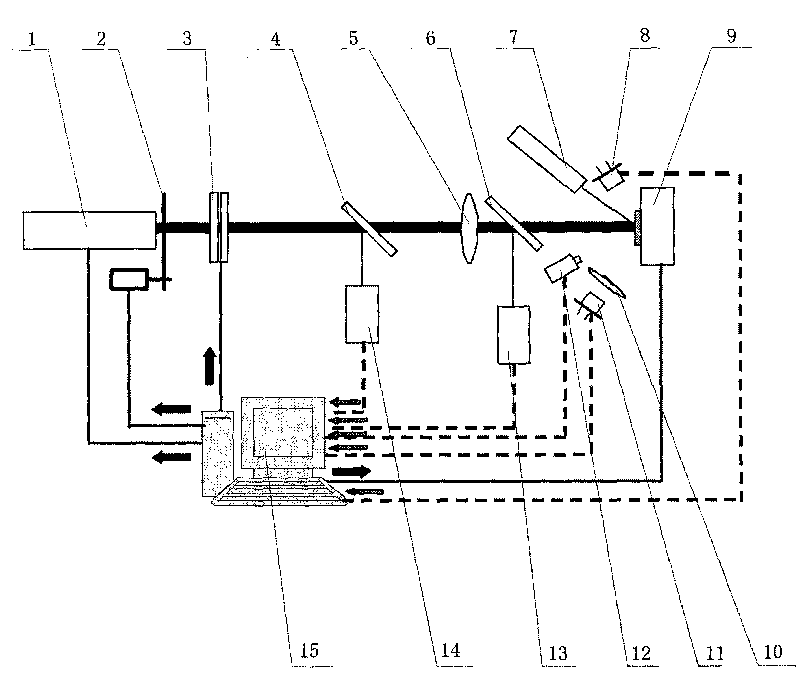

[0018] Below in conjunction with accompanying drawing, the present invention will be further described.

[0019] see figure 1 , a thin film and optical element laser damage threshold combined testing device, including a testing component and a processing component. The test components include a Nd:YAG laser 1 arranged on a main optical axis, a switch baffle 2, an attenuator 3, a first beam splitter 4, a focusing lens 5, a second beam splitter 6, an auxiliary laser 7, a photoelectric Diode array 8 , sample stage 9 , converging lens 10 , photodetection device 11 , CCD camera 12 , beam profiler 13 and energy meter 14 . Wherein the auxiliary laser 7 is set at 45 degrees away from the main optical axis, and its emission beam is towards the sample stage 9, and the said CCD camera 12 is arranged in the area between the auxiliary laser 7 reflected light beam and the main optical axis; the said photodiode array 8 is located at In the cone angle of 60 degrees of the sample surface nor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com