Polarized Airy liquid crystal formwork, preparation method and generating system

A liquid crystal and polarization technology, applied in the field of liquid crystal orientation control, which can solve the problems of low resolution, cumbersome steps, and low laser damage threshold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

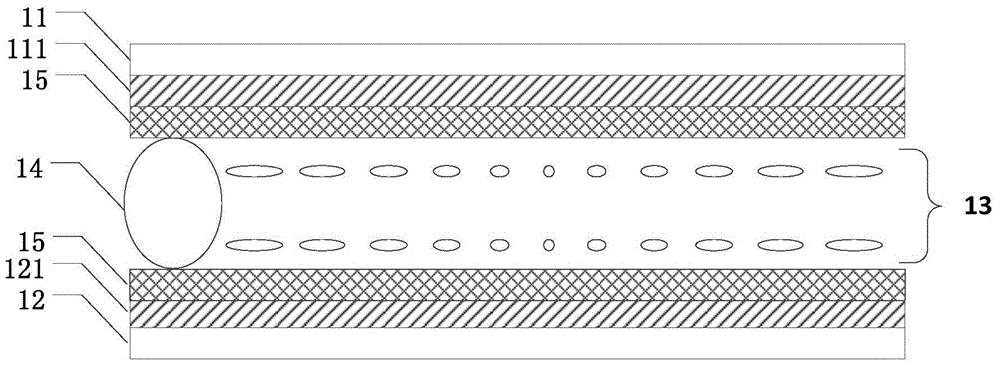

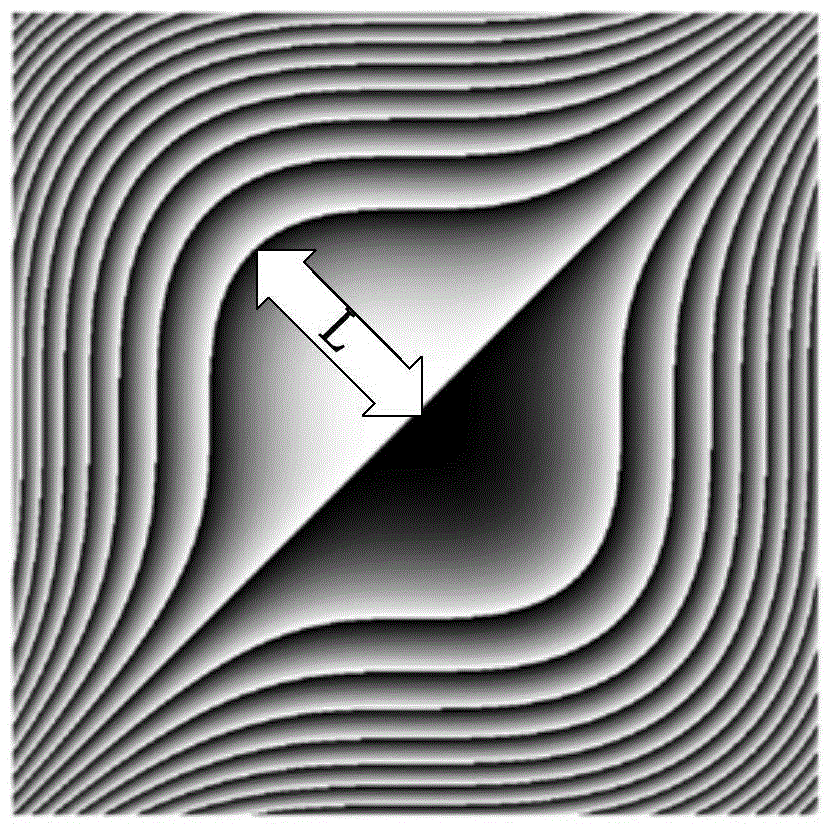

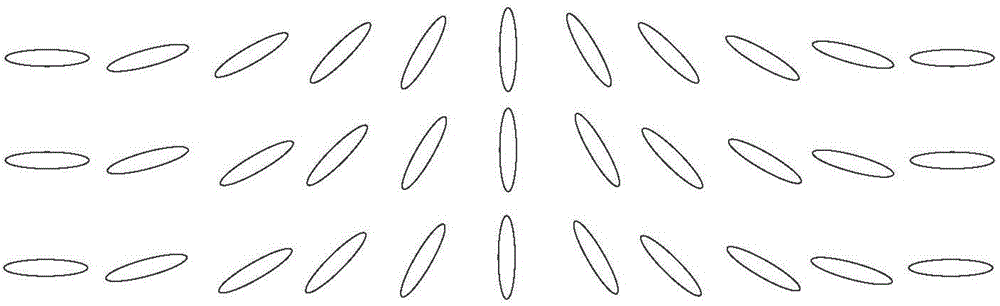

[0047] An embodiment of the present invention provides a polarized Airy liquid crystal template, figure 1 A schematic diagram of a cross-sectional structure of a polarized Airy liquid crystal template provided in Embodiment 1 of the present invention, as shown in figure 1 As shown, the polarized Airy liquid crystal template includes: a first substrate 11 and a second substrate 12 oppositely arranged, and a liquid crystal layer 13 between the first substrate 11 and the second substrate 12; wherein, the first A spacer particle 14 is arranged between the first substrate 11 and the second substrate 12 to support the liquid crystal layer 13; the side of the first substrate 11 and the second substrate 12 adjacent to the liquid crystal layer 13 is provided with a light control Alignment film 15, the photo-controlled alignment film 15 has a cubic phase control pattern whose molecular director direction is periodically and gradually changed, and the width of each cycle of the cubic pha...

Embodiment 2

[0056] Embodiment 2 of the present invention also provides an Airy beam generation system, Figure 8 A schematic structural diagram of the Airy beam generation system provided for Embodiment 2 of the present invention, as shown in Figure 8 As shown, the Airy beam generation system includes: the polarized Airy liquid crystal template 81 described in the above-mentioned embodiments, the light source 82 positioned at the incident side of the polarized Airy liquid crystal template 81 to generate incident light, and positioned at the polarized Airy liquid crystal template 81 to generate incident light. The lens 83 and the imaging device 84 on the light emitting side of the Airy liquid crystal template 81, wherein the optical axes of the light source 82, the polarized Airy liquid crystal template 81, the lens 83 and the imaging device 84 are located on the same straight line. Turn on the light source 82 to emit incident light, and irradiate the incident light of the polarized Airy ...

Embodiment 3

[0061] Embodiment 3 of the present invention also provides a method for preparing a polarized Airy liquid crystal template, Figure 10 A schematic flow chart of a method for preparing a polarized Airy liquid crystal template provided in Embodiment 3 of the present invention, as shown in Figure 10 shown. The methods include:

[0062] Step 110, forming a photo-alignment film on one side of the first substrate and the second substrate;

[0063] Optionally, before forming the photo-controlled alignment film, in order to increase the wettability and adhesion between the photo-controlled alignment film and the first substrate and the second substrate, use ITO (indium tin oxide conductive film) washing solution (acetone, alcohol, etc.) Mixed reagents) were ultrasonically cleaned for 30 minutes, and then ultrasonically cleaned twice with ultrapure water for 10 minutes each. After drying in an oven at 120° C. for 40 minutes, UVO (ultraviolet ozone) cleaning was performed for 30 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com