Pretreatment method of atmospheric plasma on surface of automobile accessory

A technology of atmospheric pressure plasma and auto parts, applied in the direction of surface pretreatment, device for coating liquid on the surface, chemical instruments and methods, etc., can solve the problems of unqualified products, low production efficiency, cumbersome procedures, etc. Achieve the effects of saving grinding and high-pressure washing, improving production efficiency and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

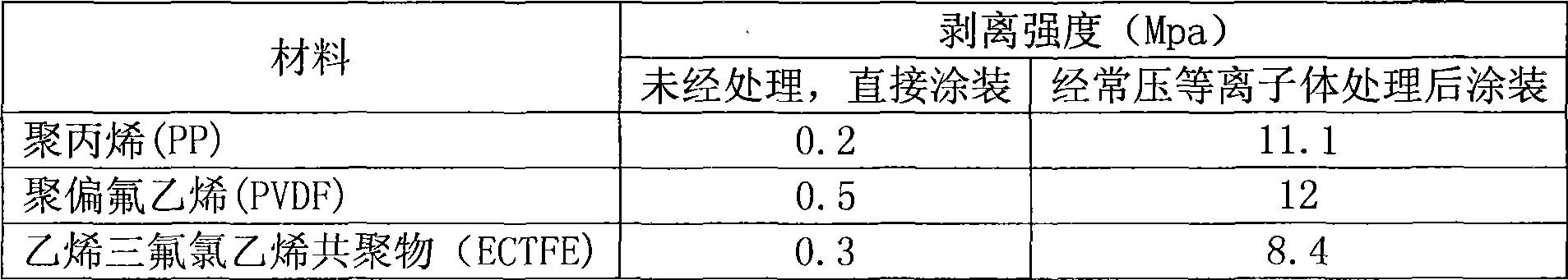

Examples

Embodiment Construction

[0017] The present invention is described further below:

[0018] Place the workpiece to be processed on the working table of the atmospheric pressure plasma processing equipment; the spray gun of the atmospheric pressure plasma processing equipment moves at a constant speed relative to the workpiece at a position of 3 mm to 40 mm from the surface of the workpiece, and dissociates the air from the air under normal pressure into The plasma beam is sprayed onto the surface of the workpiece, and the surface of the workpiece is treated with atmospheric pressure plasma.

[0019] Plasma, also known as plasma, is an ionized gas-like substance composed of atoms deprived of some electrons and positive and negative electrons generated after atoms are ionized; when the temperature of ordinary gas rises, the thermal motion of gas particles intensifies, making the particles A strong collision occurs between them, and electrons in a large number of atoms or molecules are knocked off, thereb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com