External bag opening shaping method of automatic vacuum packaging machine for tea and apparatus thereof

A vacuum packaging machine and vacuum packaging technology, which is applied in the directions of packaging, transportation and packaging, special packaging objects, etc., can solve the problems of the foldable edge of the outer bag mouth, waste of manpower, material resources, deformation of the outer bag mouth, etc. Achieve the effect of reducing packaging costs, improving tea quality, and working reliably

Inactive Publication Date: 2010-08-18

李文峰

View PDF4 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the existing outer bag opening mechanism and the outer bag suction mechanism are only simply pressed together, and the outer bag opening mechanism and the outer bag suction mechanism are relatively moved to press the outer bag pocket, which is easy to cause the outer bag The foldable edge of the mouth moves, which leads to the deformation of the outer bag mouth, so that the finished bag mouth after vacuum packaging is out of shape, and must be disassembled or discarded directly, which wastes manpower and material resources and increases costs.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

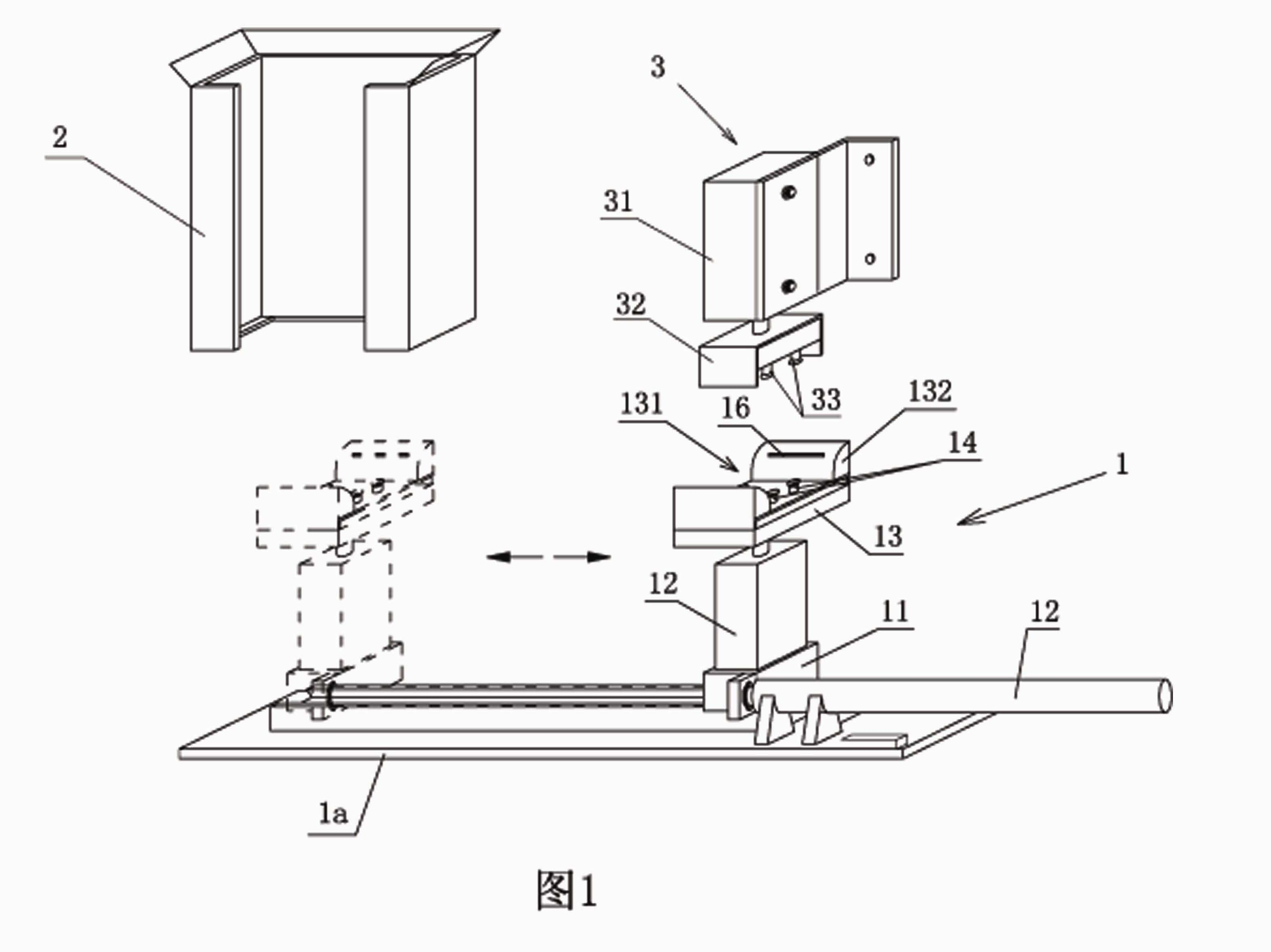

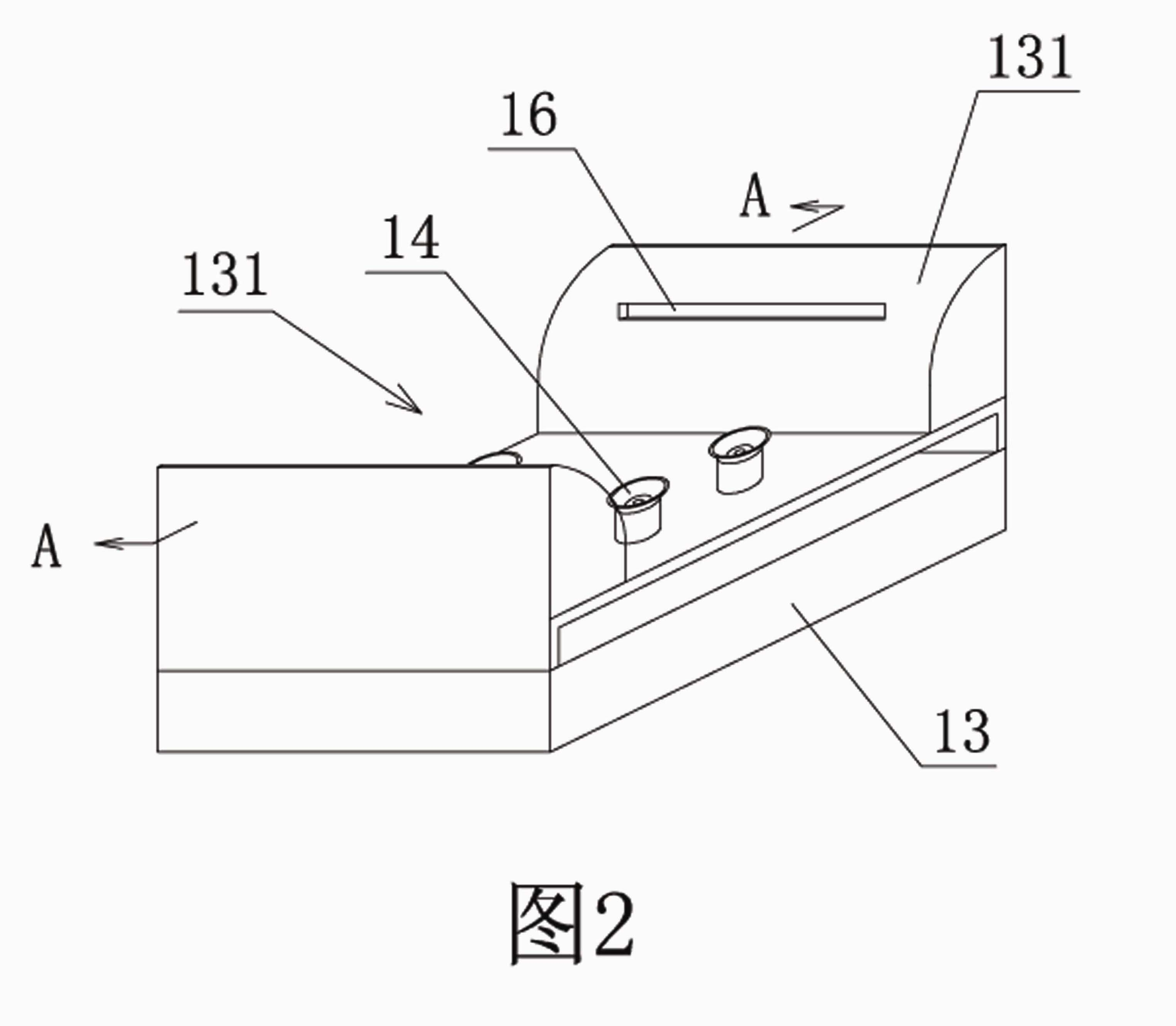

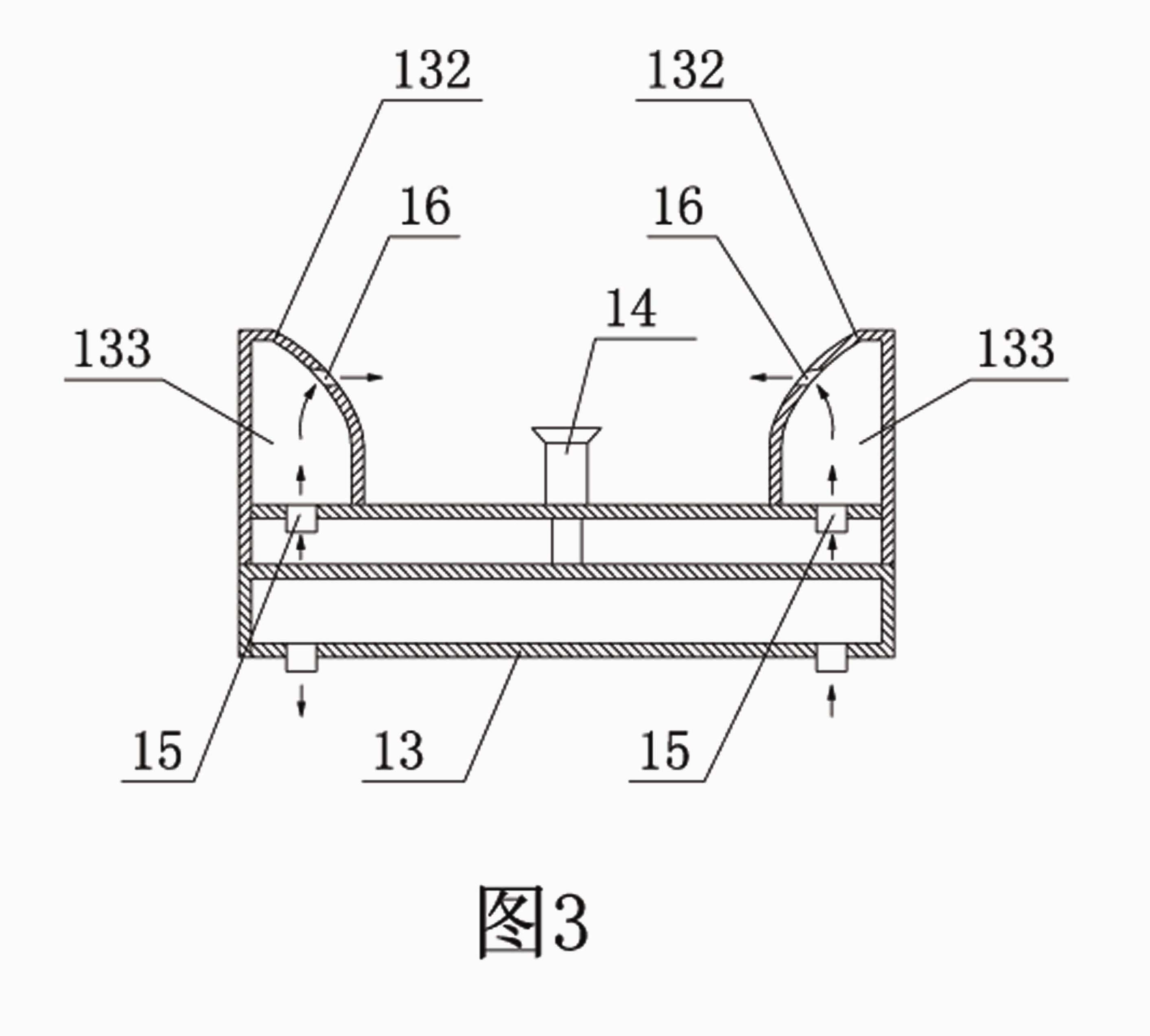

The invention provides an external bag opening shaping method of an automatic vacuum packaging machine for tea and an apparatus thereof. The apparatus comprises an empty external bag absorbing and sending mechanism, which is capable of reciprocating between an empty external bag holding device and an empty external bag expanding mechanism and is provided with a bag-fetching sucker holder with a bag-fetching sucker; a through groove is arranged at the middle of the top surface of the bag-fetching sucker holder; the bag-fetching sucker is installed on the bottom surface of the groove; the opposite sides of two side walls of the groove are correspondingly provided with a shaping and blowing opening; the bag-fetching sucker holder is provided with an air inlet for connecting an external air source and an air passage for communicating with the shaping and blowing opening and the air inlet. After the empty external bag is charged, in the process that the bag expanding sucker and the bag-fetching sucker are close to each other again, the shaping and blowing opening aims at the middle part of the foldable side of the empty external bag and blows continuously; the continuous blowing forcibly makes the middle part of the foldable side of the empty external bag fold inwards and ensures that the external bag opening recovers the folded shape of the side after the bag expanding sucker and the bag-fetching sucker are compacted with each other. The invention has the advantages of simple structure, reliable work, automatic shaping of the external bag opening and improvement of the excellent rate of the finished product to the maximum.

Description

[0001] Technical field [0002] The invention belongs to automatic tea packaging equipment, in particular to a method and device for shaping the outer bag opening of an automatic vacuum packaging machine for tea. [0003] Background technique [0002] In order to prolong the shelf life, freshness, moisture and odor of tea, facilitate storage and better adapt to the needs and use of consumers at different levels, the tea is usually vacuum-packaged and sold in small packages of 5-10 grams. In order to realize the automatic filling of the outer bag, the current common vacuum packaging machines include an outer bag suction mechanism and an outer bag opening mechanism matched with the outer bag suction mechanism. The outer bag suction mechanism is placed from the outer bag. An empty outer bag is sucked from the dispenser and transferred to the corresponding position of the outer bag opening mechanism. The opening of the empty outer bag is expanded by the outer bag opening mechanism, a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B65B31/00B65B43/18B65B43/30

Inventor 李文峰

Owner 李文峰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com