Flexible all-coating soft film and preparation method thereof

A flexible and soft film technology, applied in the field of flexible all-inclusive soft film and its preparation, can solve the problems of short service life, falling off of the protective film, affecting the use effect, etc., to achieve automatic repair of scratches, simplify the production process, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

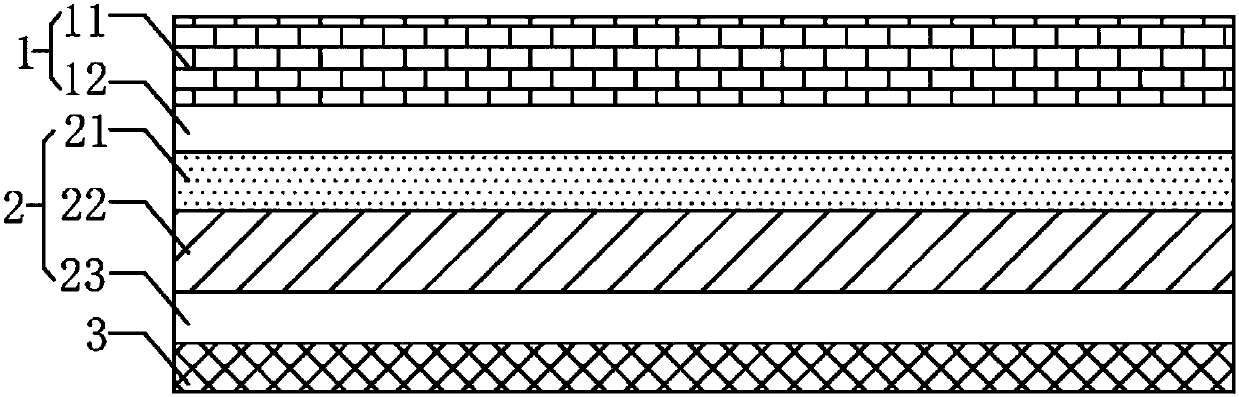

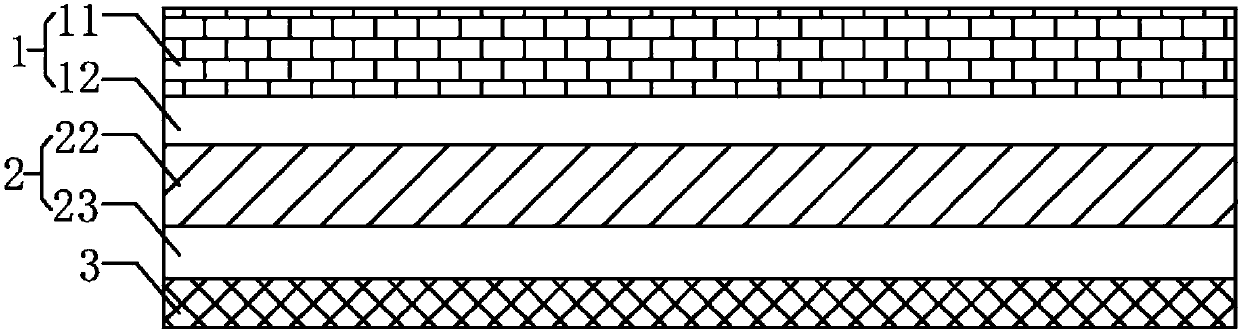

[0041] See figure 1 , a flexible all-encompassing soft film, including a protective film layer 1, a use layer 2 and a peeling layer 3 that are sequentially bonded from top to bottom, and the protective film layer 1 includes a substrate layer 11 that is sequentially bonded from top to bottom And the protective film adhesive layer 12, the use layer 2 includes a self-repairing layer 21, a flexible soft film layer 22 and an adhesive layer 23 that are laminated sequentially from top to bottom, and the lower surface of the protective film adhesive layer 12 is in contact with the The upper surface of the self-healing layer 21 is attached, and the lower surface of the adhesive layer 23 is attached to the upper surface of the release layer 3 .

[0042] The substrate layer 11 is a PET film with a thickness of 23 μm; the protective film adhesive layer 12 is a silicone pressure-sensitive adhesive layer with a thickness of 5 μm and a peeling force of 1 gf / 25 mm.

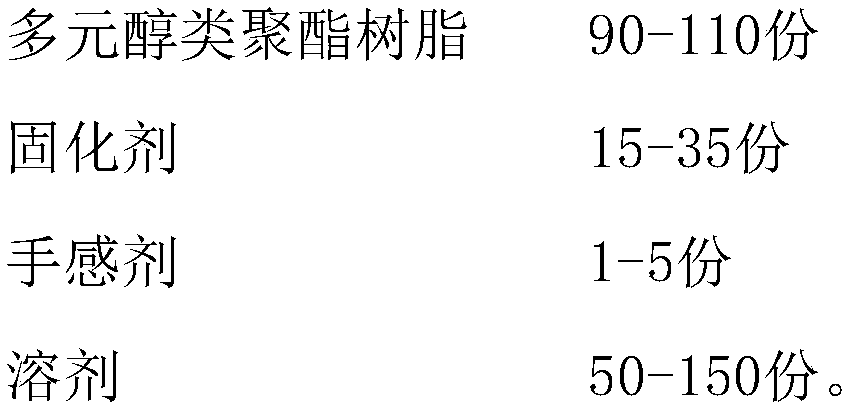

[0043] The self-healing ...

Embodiment 2

[0054] A flexible all-encompassing soft film, comprising a protective film layer 1, a use layer 2 and a peeling layer 3 that are laminated sequentially from top to bottom, and the protective film layer 1 includes a substrate layer 11 and a substrate layer that are sequentially laminated from top to bottom The protective film adhesive layer 12, the use layer 2 includes a self-repairing layer 21, a flexible soft film layer 22 and an adhesive layer 23 that are laminated sequentially from top to bottom, and the lower surface of the protective film adhesive layer 12 and the self-repairing layer The upper surface of the repairing layer 21 is attached, and the lower surface of the adhesive layer 23 is attached to the upper surface of the release layer 3 .

[0055] The substrate layer 11 is a PET film with a thickness of 35 μm; the protective film adhesive layer 12 is a silicone pressure-sensitive adhesive layer with a thickness of 8 μm and a peeling force of 2 gf / 25 mm.

[0056] The ...

Embodiment 3

[0066] A flexible all-encompassing soft film, comprising a protective film layer 1, a use layer 2 and a peeling layer 3 that are laminated sequentially from top to bottom, and the protective film layer 1 includes a substrate layer 11 and a substrate layer that are sequentially laminated from top to bottom The protective film adhesive layer 12, the use layer 2 includes a self-repairing layer 21, a flexible soft film layer 22 and an adhesive layer 23 that are laminated sequentially from top to bottom, and the lower surface of the protective film adhesive layer 12 and the self-repairing layer The upper surface of the repairing layer 21 is attached, and the lower surface of the adhesive layer 23 is attached to the upper surface of the release layer 3 .

[0067] The substrate layer 11 is a PET film with a thickness of 50 μm; the protective film adhesive layer 12 is a silicone pressure-sensitive adhesive layer with a thickness of 11 μm and a peeling force of 3 gf / 25 mm.

[0068] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com