Method for making foam shoe body by integral forming

A manufacturing method and an integrated technology, which can be applied to footwear, other home appliances, home appliances, etc., and can solve problems such as soles that are not suitable for multi-color systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

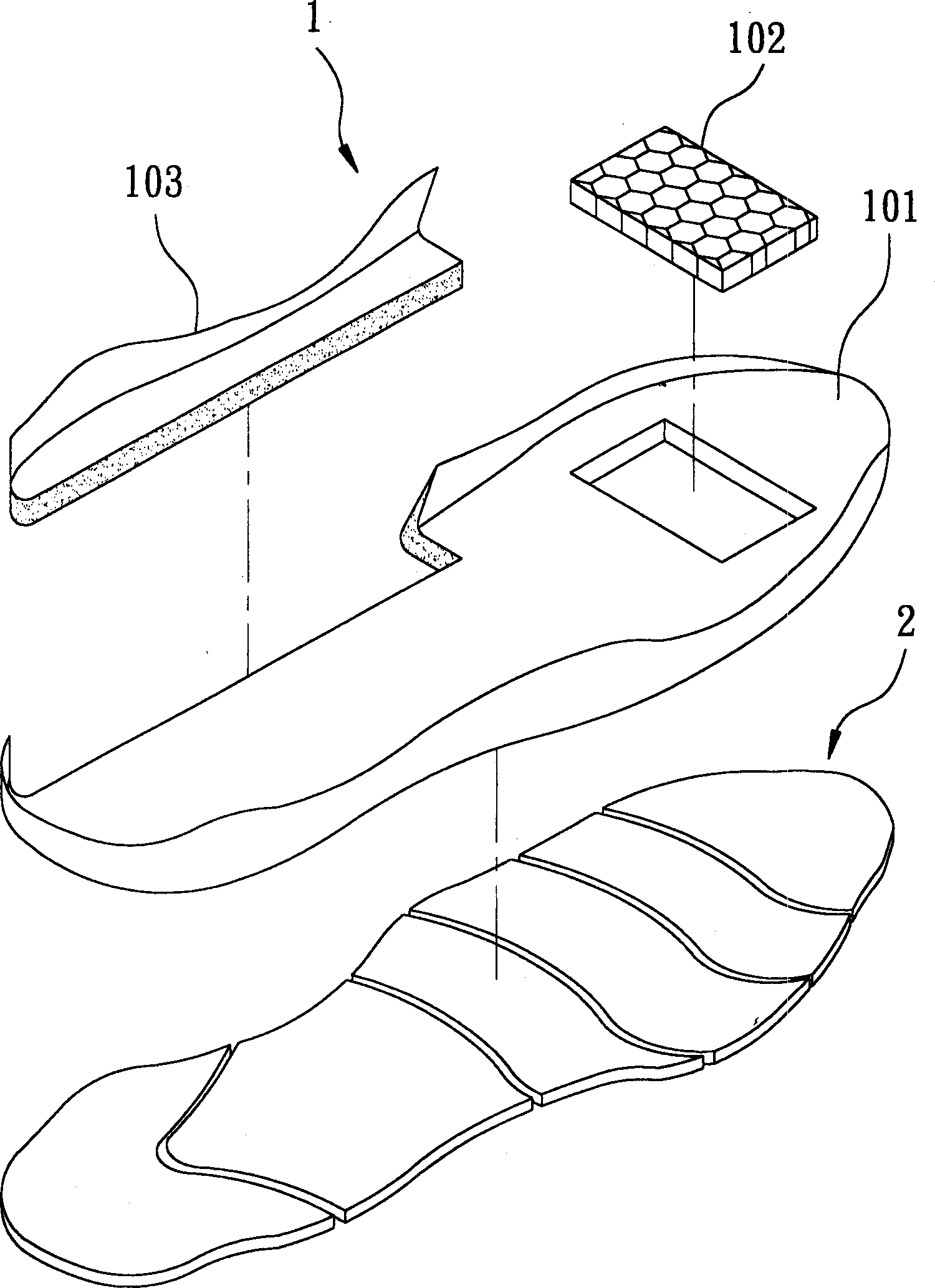

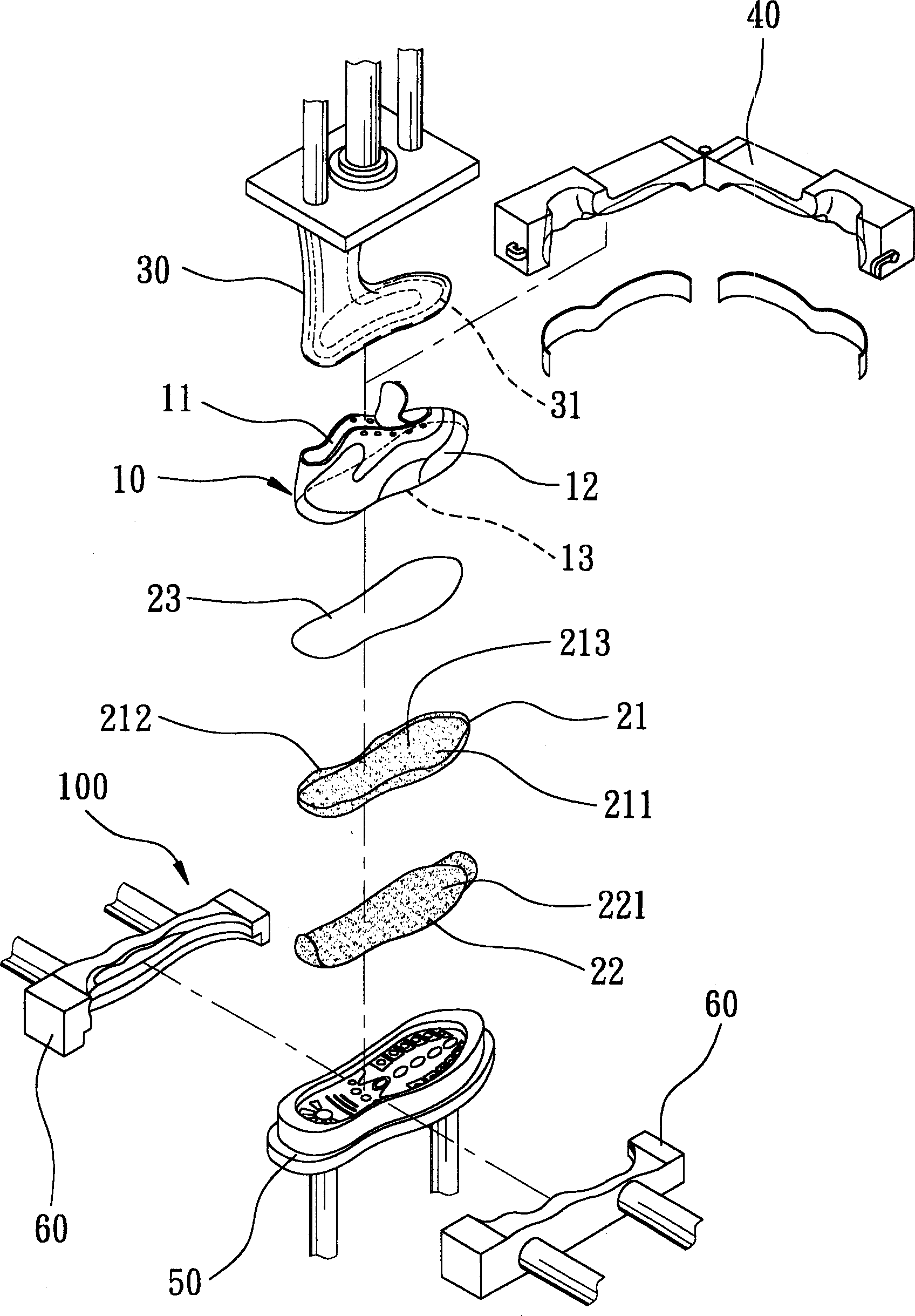

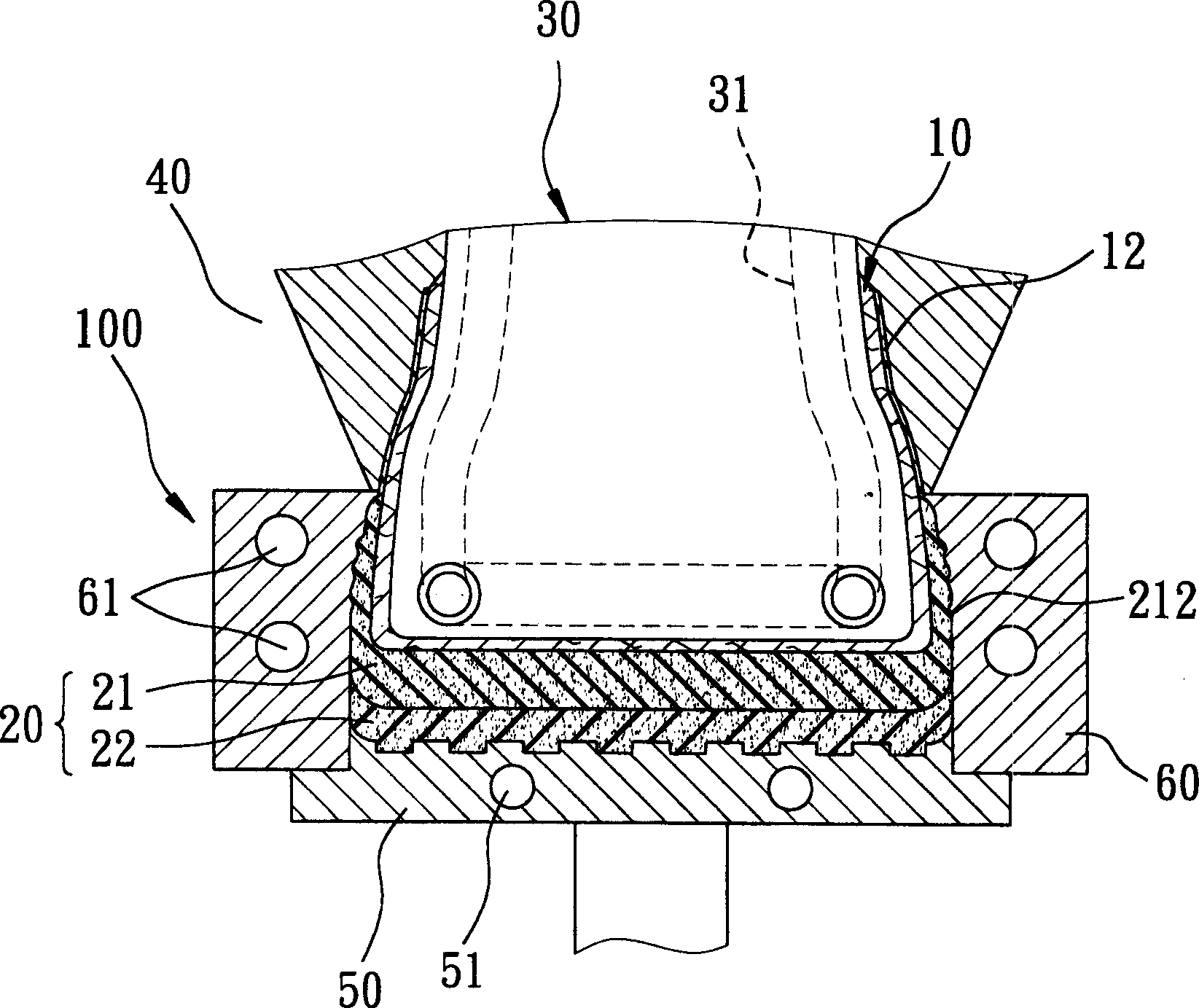

[0025] refer to figure 2 , 3 As shown, the first preferred embodiment of the manufacturing method of foamed shoe body integral molding of the present invention includes the following steps:

[0026] 1. Preparation of a shoe upper component and a shoe sole unit: the shoe upper component 10 is formed by combining more than one piece of material by sewing, and has a top opening 11 at the top edge, an outer surface 12 surrounding the outer circumference, and A bottom surface 13 located at the bottom of the shoe upper assembly 10 and connected to the outer surface 12, the sole unit 20 in this embodiment includes a foamed EVA shoe midsole blank 21 and a preformed shoe outsole 22, wherein the shoe midsole embryo 21 is a semi-finished product with a size slightly larger than the finished product, and has a top surface 211 and a side wall 212 extending upward from the periphery of the top surface 211. The two cooperate to define a chamber 213 that can accommodate objects.

[0027] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com