Organic light emitting display device with touch screen function and manufacturing method thereof

A technology of light-emitting display and touch function, applied in semiconductor/solid-state device manufacturing, input/output process of data processing, instruments, etc. The effect of compact structure and high product quality rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

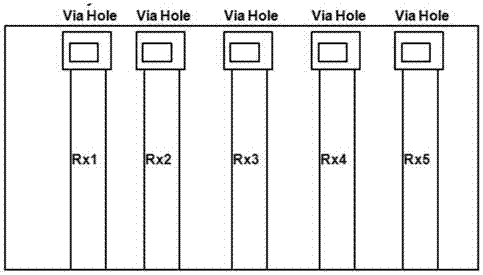

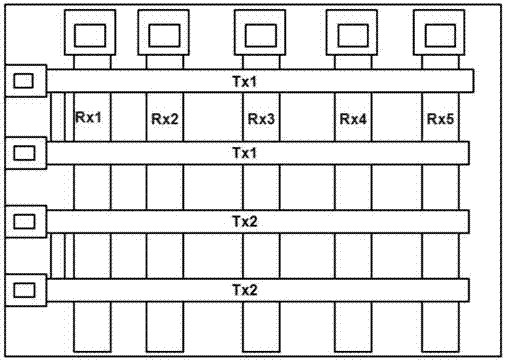

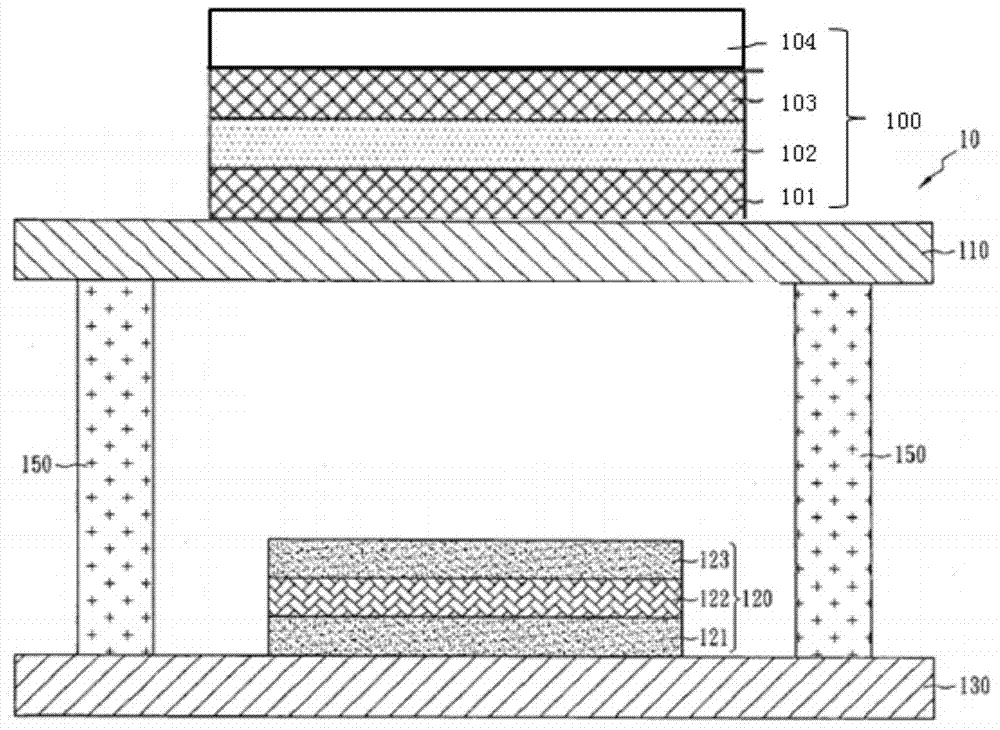

[0036] At present, traditional OLED displays can also be integrated with touch technology, please refer to figure 1 A schematic diagram of the cross-sectional structure of the OLED touch display device. As shown in the figure, the touch display device 10 is mainly composed of an OLED structure to achieve a display function. The structure includes a lower substrate 130, a top cover 110, an OLED device 120 and a sealing layer 150, wherein the OLED device 120 It is stacked above the lower substrate 130 , and the upper cover 110 is further disposed above the OLED device 120 and integrated with the lower substrate 130 through the sealing layer 150 . In order to allow the device 10 to have a touch function at the same time, a capacitive touch sensing layer 100 is formed on the upper cover 110. The capacitive touch sensing layer 100 is composed of a first transparent conductive layer 101, an insulating layer 102 , a second transparent conductive layer 103 and an insulating protectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com