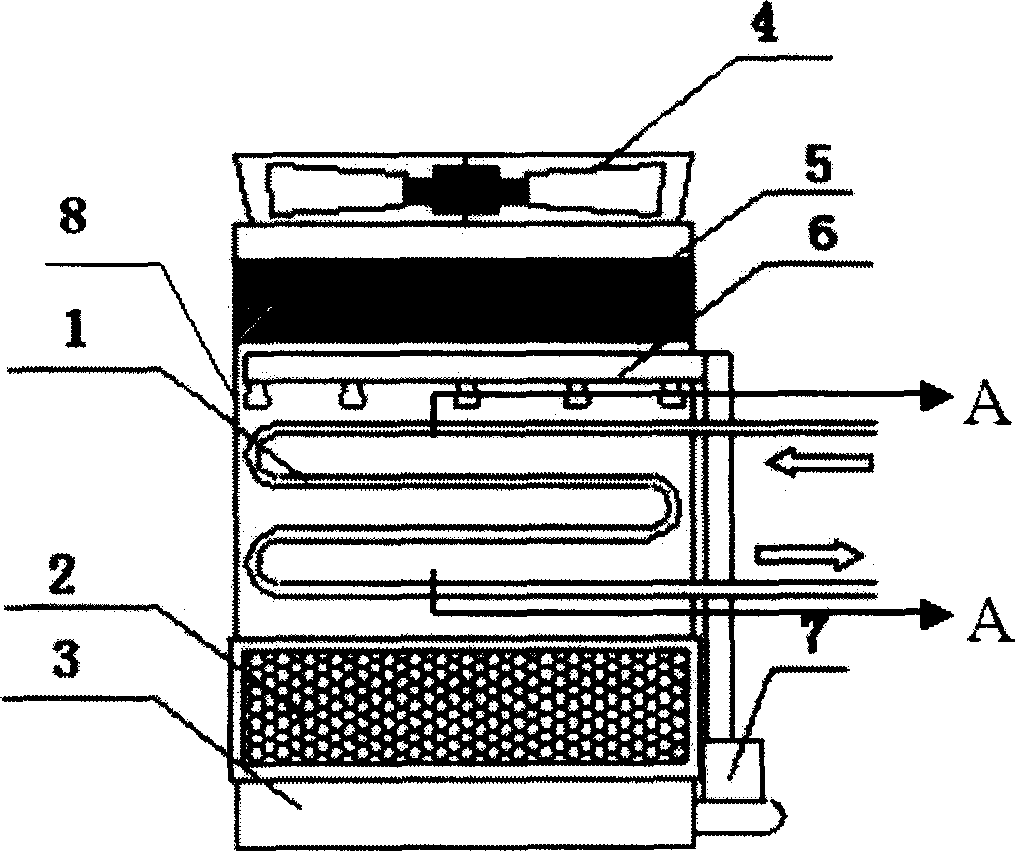

Spring tube evaporation type cold exchange device

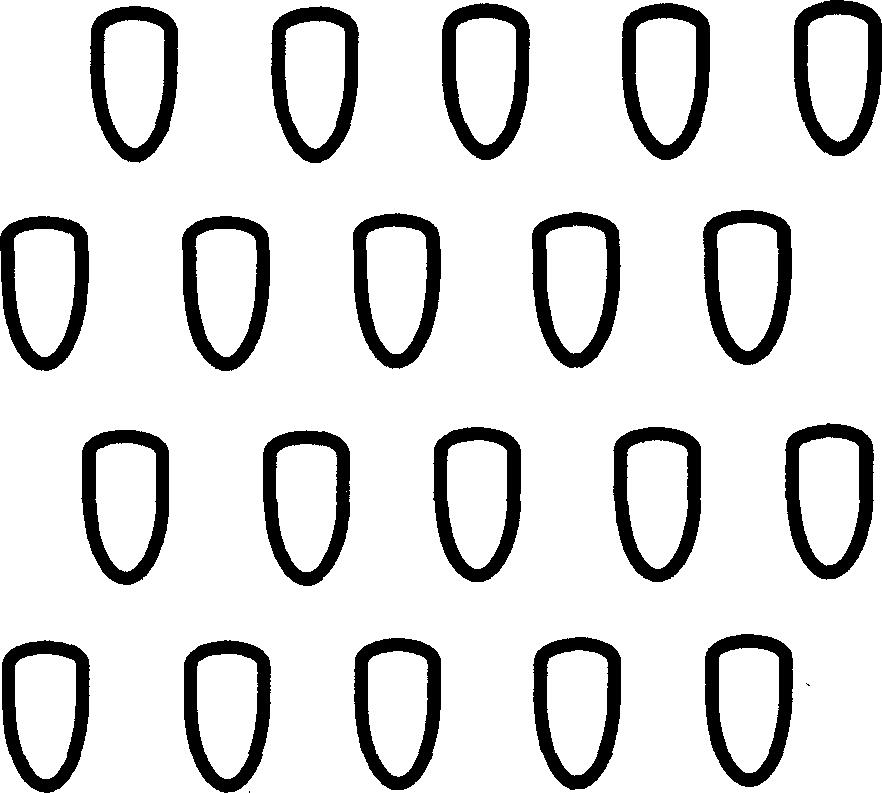

An evaporative and elastic technology, applied in heat exchange equipment, lighting and heating equipment, tubular elements, etc., can solve the problems of reducing air flow resistance, large flow resistance, increasing energy consumption, etc., to increase heat exchange area, Strengthen the renewal process and increase the effect of heat transfer temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] specific implementation

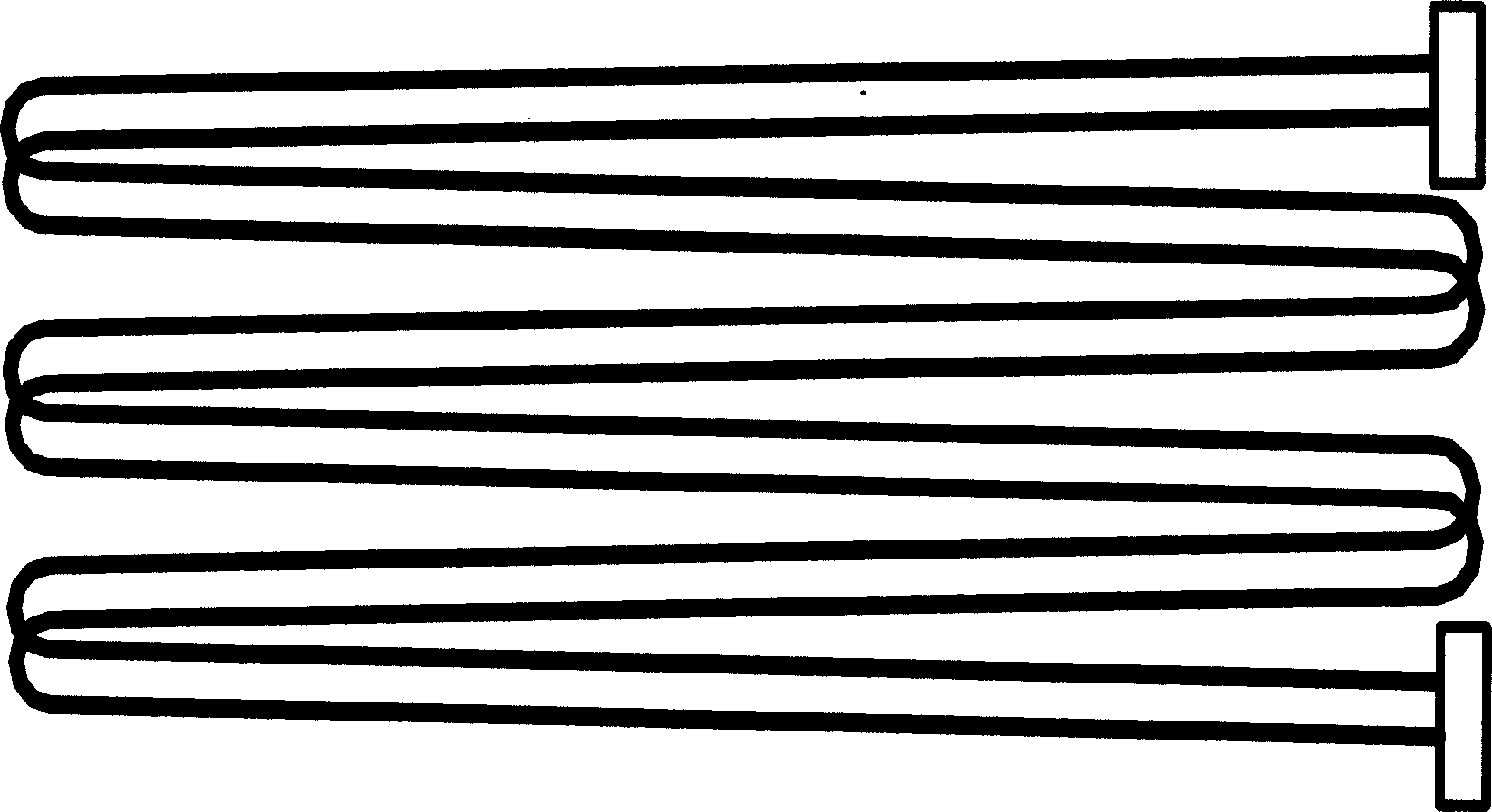

[0021] The general mode of realizing the present invention can be following process: (1) according to figure 1 The processing and manufacturing method and technology of the bullet-shaped tube evaporative cooling equipment shown can be processed, manufactured and installed by using the processing, manufacturing and technology of ordinary evaporative cooling equipment. Specifically, steel, copper and copper can be used. , aluminum and other metals are used as materials, and the general machining and connection methods are used to process, manufacture and install; (2) first design, process and manufacture the various parts and connectors of the cooling equipment, the cooling equipment box 8 and the water collection tank 3 It can be formed by connecting steel plates through connecting parts. The air inlet grid 2 and water retaining grid 5 can be processed by general grid processing technology and equipment. The fan 4, water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com