Medical clamp and processing method thereof

A processing method and forceps head technology, applied in the field of medical forceps, can solve the problems of easy breakage, poor bonding reliability, and insufficiently dense knife-edge tissue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

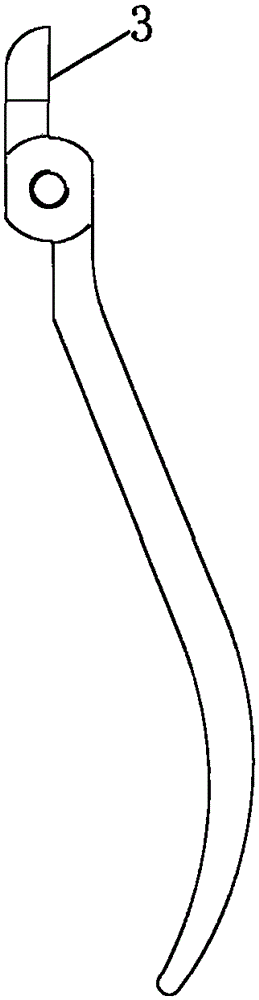

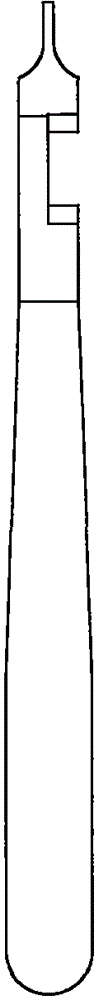

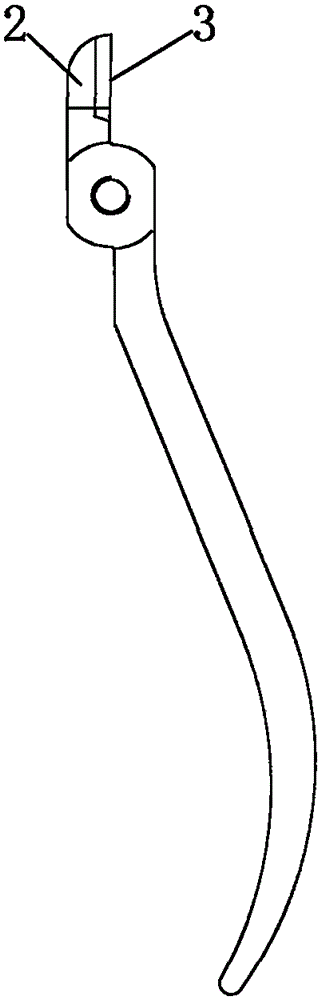

[0072] Embodiment 1: a kind of medical forceps, such as Figure 5 , 6 shown, including:

[0073] The clamp head 2 is made of medium-low hardness stainless steel material; the clamp head 2 and the handle 1 are integrally formed of medium-low hardness stainless steel material, and the clamp head 2 is used as the base body of the welding jaw 3;

[0074] Jaw 3 made of harder stainless steel; jaw 3 is the part of the pliers that is in direct contact with the steel wire when in use, and is a general term for thicker jaws and thinner knife edges; harder stainless steel material is relative to For medium and low hardness stainless steel materials, its hardness is higher than that of medium and low hardness stainless steel materials, such as high hardness stainless steel materials;

[0075] As a flux for bonding pliers and jaws;

[0076] The pliers 2 and the jaws 3 are melted with flux while quenching to weld them together. The flux is cladding on the joint and joint surface of the...

Embodiment 2

[0081] Embodiment 2: a kind of medical forceps, such as Figure 14 , 15 shown, including:

[0082] The pincers 2 made of 17-4 stainless steel, the jaws 3 made of 11Cr17Mo stainless steel; the flux 5 used for bonding the pincers 2 and the jaws 3; the pincers 2 and the jaws 3 are in While quenching, the flux 5 is melted to weld them together; at the same time, the clamp head 2 and jaw 3 are connected together by stainless steel screws 6 , and the threads of the stainless steel screws 6 are clad with flux 5 .

[0083] The flux is cladding on the joint and joint surface of the pliers head 2 and the jaw 3, and the flux is one of nickel-based brazing material, silver-based brazing material or gold-based brazing material Or several kinds of mixed brazing materials.

[0084] The processing method of the above-mentioned medical forceps is as follows:

[0085] Such as Figure 14 , Figure 15 As shown, first, the handle 1 and the jaw 2 are made of 17-4 stainless steel, and the jaw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com