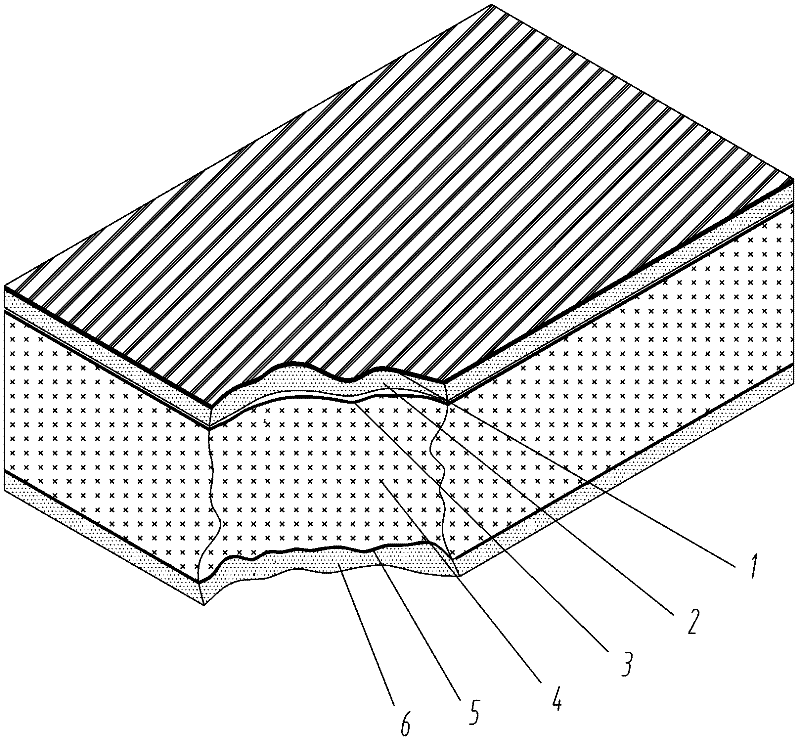

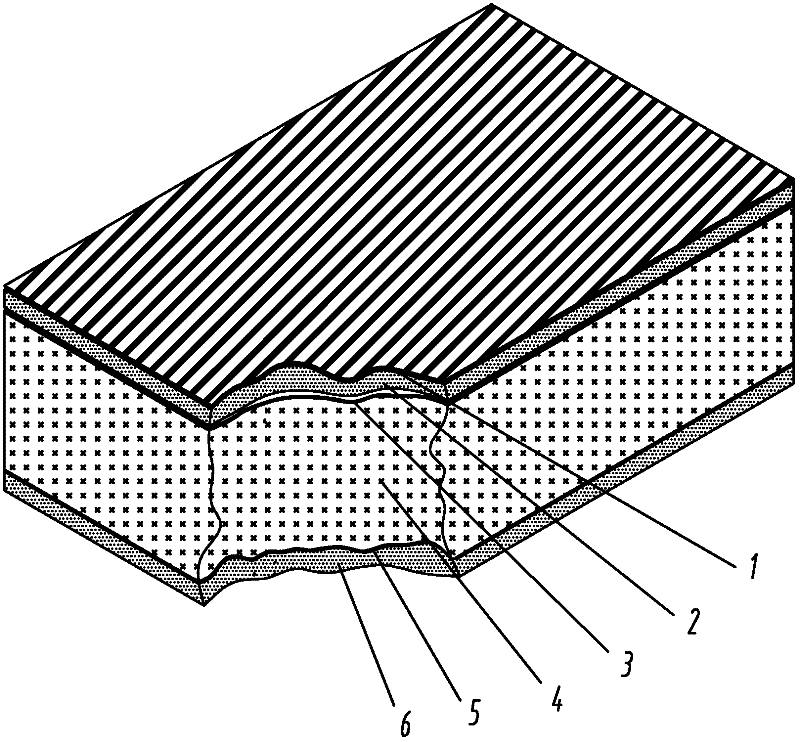

Low-carbon fireproof thermal insulation decoration integrated board and preparation method thereof

A technology of fire-proof and heat-preserving integrated panels, which is applied in the field of architectural decorative panels, can solve the problems of poor durability, easy to fall off, easy to crack, etc., and achieve the effects of reducing ecological environment damage, good thermal insulation performance, decoration, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] A method for preparing a low-carbon fire-proof, heat-preservation and decorative integrated board is carried out according to the following steps,

[0057] Step 1: Prepare the surface layer of inorganic mineral tailings

[0058] First, aluminum magnesium silicate powder 10-50, light-burned magnesium powder 1-50, magnesium cementitious material regulator 1-50, silica fume powder 1-20, phosphoric acid or sulfate powder 1-10, ore tailings 1-70, mineral sand or colored quartz sand 1-70, hollow glass beads 3-30, iron oxide ore powder 1-20, mineral wool fiber 1-30, reinforced glass fiber 1-30, polypropylene fiber 1-30, Lignin 5-30, mica powder 5-30, according to the ratio, stir evenly at high speed (stirring speed at 800-1600 rpm) to form surface layer raw materials, and spread evenly on the surface under vacuum and balanced temperature conditions of 10-30 degrees Celsius On the smooth surface of the resin mold, the average paving thickness is 3-5mm;

[0059] Step 2: Pave t...

Embodiment 1

[0077] Inorganic mineral tailings surface layer of low-carbon fireproof, thermal insulation and decorative integrated board, by weight, 1Kg / part

[0078] Aluminum magnesium silicate powder 10 Kg, lightly burned magnesium powder 5Kg, magnesium cementitious material regulator 1 Kg,

[0079] Silica fume powder 10Kg, phosphoric acid or sulfate powder 1 Kg, ore tailings 70 Kg,

[0080] 1 Kg of ore sand or colored quartz sand, 3 Kg of hollow microspheres, 1 Kg of iron oxide ore powder,

[0081] Mineral wool fiber 1 Kg, reinforced glass fiber 3 Kg, polypropylene fiber 1 Kg,

[0082] Lignin 5 Kg, mica powder 10Kg.

[0083] The inorganic-organic composite thermal insulation core layer, in parts by weight, 1Kg / part

[0084] Aluminum magnesium silicate powder 10 Kg, lightly burned magnesium powder 5 Kg, silica fume powder 20 Kg,

[0085] Magnesium cementitious material regulator 10 Kg, phosphoric acid or sulfate powder 1 Kg, ore tailing powder 1 Kg, ore sand or colored quartz sand 1 ...

Embodiment 2

[0089] Inorganic mineral tailings surface layer of low-carbon fireproof, thermal insulation and decorative integrated board, by weight, 1Kg / part

[0090] 50 Kg of aluminum magnesium silicate powder, 50 Kg of lightly burned magnesium powder, 50 Kg of magnesium cementitious material regulator,

[0091] Silica fume powder 20 Kg, phosphoric acid or sulfate powder 1 Kg, ore tailings 1 Kg,

[0092] Ore sand or colored quartz sand 1-70, hollow glass beads 3-30, iron oxide ore powder 1 Kg,

[0093] Mineral wool fiber 30 Kg, reinforced glass fiber 1 Kg, polypropylene fiber 30 Kg,

[0094] Lignin 15 Kg, mica powder 30Kg.

[0095] The inorganic-organic composite thermal insulation core layer, in parts by weight, 1Kg / part

[0096] Aluminum magnesium silicate powder 50 Kg, lightly burned magnesium powder 50 Kg, silica fume powder 1-20,

[0097] Magnesium cementitious material regulator 1 Kg, phosphoric acid or sulfate powder 10 Kg, ore tailing powder 70 Kg, ore sand or colored quartz san...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com