Method of co-processing zinc-rich gypsum slag and jarosite slag

A co-processing and gypsum slag technology, applied in the direction of zinc sulfide, calcium carbonate/strontium/barium, etc., to achieve significant environmental benefits, mild process conditions, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

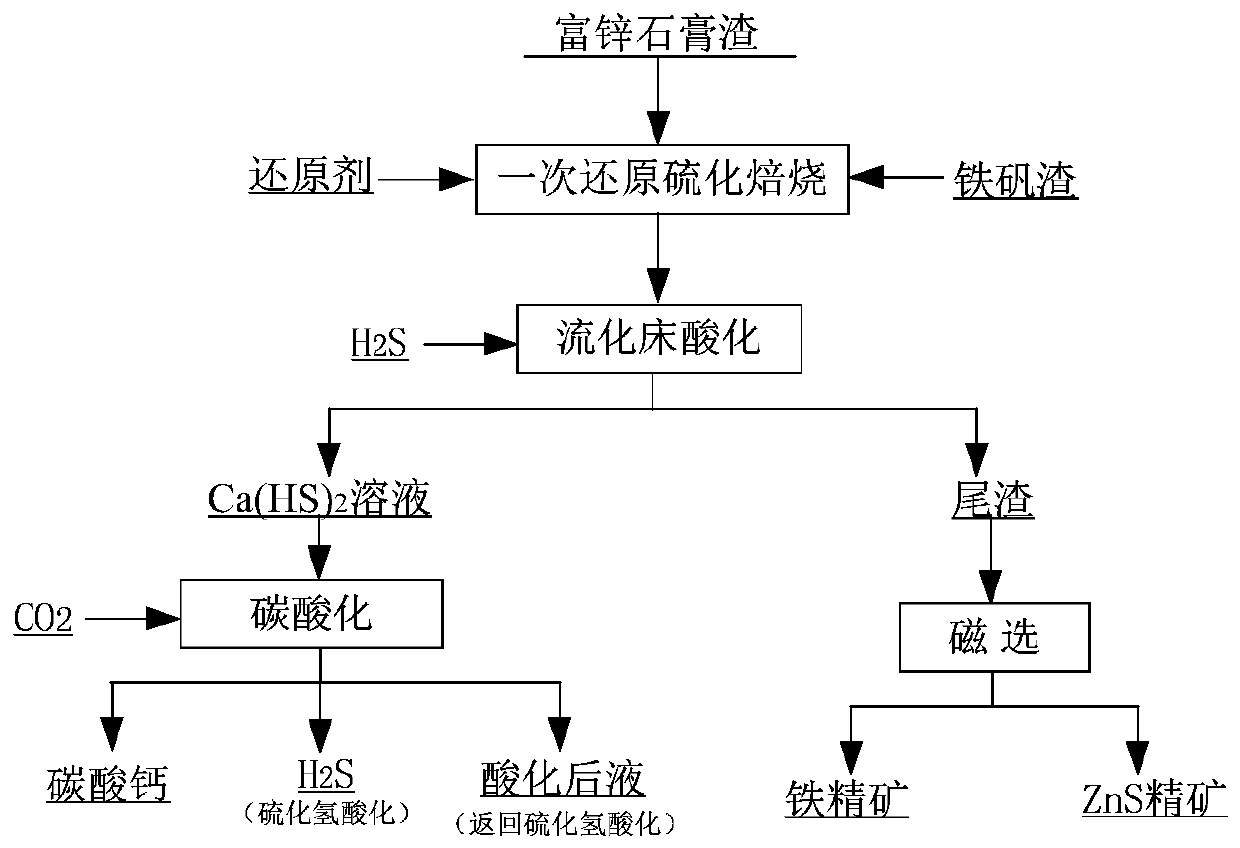

Method used

Image

Examples

Embodiment 1

[0054] The zinc-rich gypsum slag and jarosite slag used in this example come from a large-scale zinc smelter in Zhuzhou, and their specific components are shown in Table 1 and Table 2 respectively. The main components of the zinc-rich slag are calcium sulfate dihydrate and zinc hydroxide, sulfuric acid dihydrate The calcium content is 65.6%, and the zinc hydroxide content is 18.3%.

[0055] Table 1 Main chemical composition / % of zinc-rich gypsum slag

[0056]

[0057] The main chemical composition / % of table 2 jarosite slag

[0058]

[0059] A method for the co-processing of zinc-rich gypsum slag and jarosite slag, the specific steps are as follows:

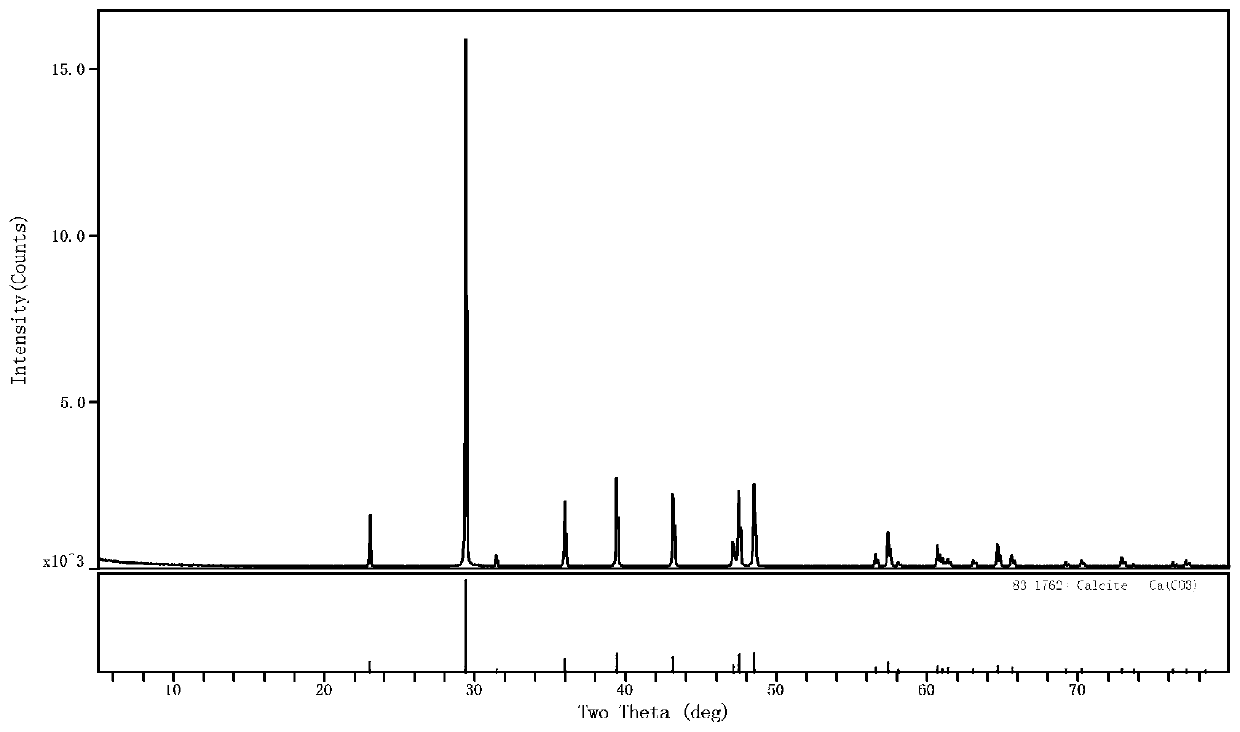

[0060] (1) Get the above-mentioned naturally air-dried zinc-rich gypsum slag 1000kg and 600kg of alumite slag and 400kg of coke powder with a particle size of 80% less than 1mm and mix evenly (gypsum slag: jarosite slag: coke powder is 100:60:50), Put the above mixed and briquetted material in a vacuum reduction furnace, ...

Embodiment 2

[0070] The zinc-containing gypsum slag used in this example comes from a large-scale zinc smelter in Qujing, Yunnan, and its specific components are shown in Table 3. The main components of the gypsum slag are dihydrate, calcium sulfate and zinc hydroxide, and the content of calcium sulfate dihydrate is 87.5%. The zinc hydroxide content is 8.63%, and the main components of the used jarosite slag are shown in Table 2.

[0071] Table 3 Main chemical composition / % of zinc-containing gypsum slag

[0072]

[0073] A method for the co-processing of zinc-rich gypsum slag and jarosite slag, the specific steps are as follows:

[0074] (1) getting the above-mentioned naturally air-dried zinc-rich gypsum slag 1000kg and 400kg of gypsum slag and 400kg of particle size is 80% less than 1mm pulverized coal mixing (gypsum slag: gypsum slag: pulverized coal is 100:40:40), Put the above-mentioned mixed and briquetted material in a vacuum reduction furnace, first roast at 400°C for 60 minut...

Embodiment 3

[0087] The main components of zinc-containing gypsum slag and jarosite slag used in this embodiment are shown in Table 1 and Table 2 respectively.

[0088] A method for the co-processing of zinc-rich gypsum slag and jarosite slag, the specific steps are as follows:

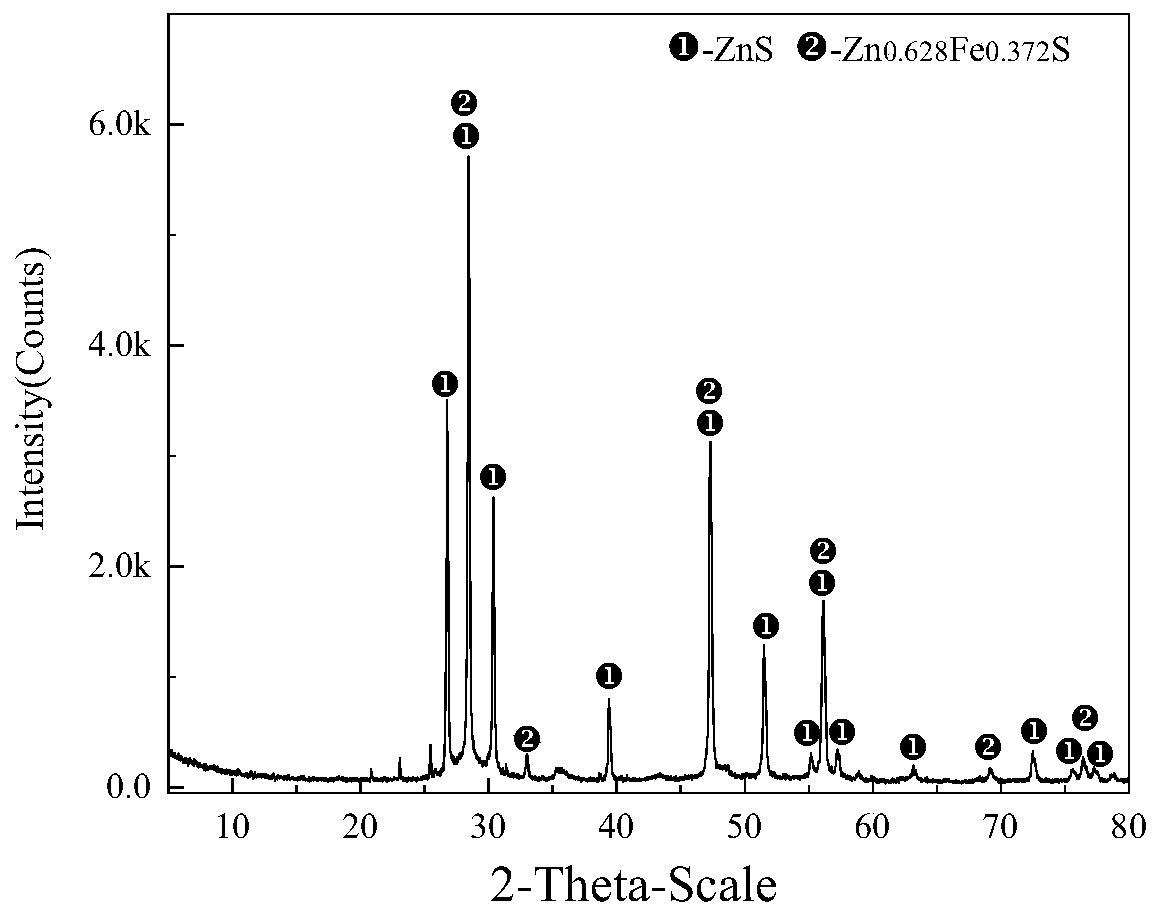

[0089] (1) get the above-mentioned naturally air-dried zinc-rich gypsum slag 1000kg and 800kg of gypsum slag and 600kg of particle size and mix evenly (gypsum slag: gypsum slag: pulverized coal is 100:80:60), Put the above-mentioned mixed and briquetted material in a vacuum reduction furnace, first roast at 400°C for 60 minutes to remove crystal water and free water in the material, and then reduce and sulfide roast at 1100°C for 90 minutes; the roasted sample is cooled to room temperature Take out after; Through chemical analysis, the result shows that the content of zinc, calcium sulfide, total sulfur and metallic iron in the zinc sulfide in the roasted sample is respectively 18.5%, 49.5%, 30.4% and 24.2%, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com