Non-combustible air purification acoustic absorption composite material as well as preparation method thereof

A composite material and air purification technology, applied in chemical instruments and methods, synthetic resin layered products, sound-generating devices, etc., can solve problems such as low tensile strength and easy shedding of surface fibers, and achieve good sound absorption, soft touch, Overcomes the effect of easy shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

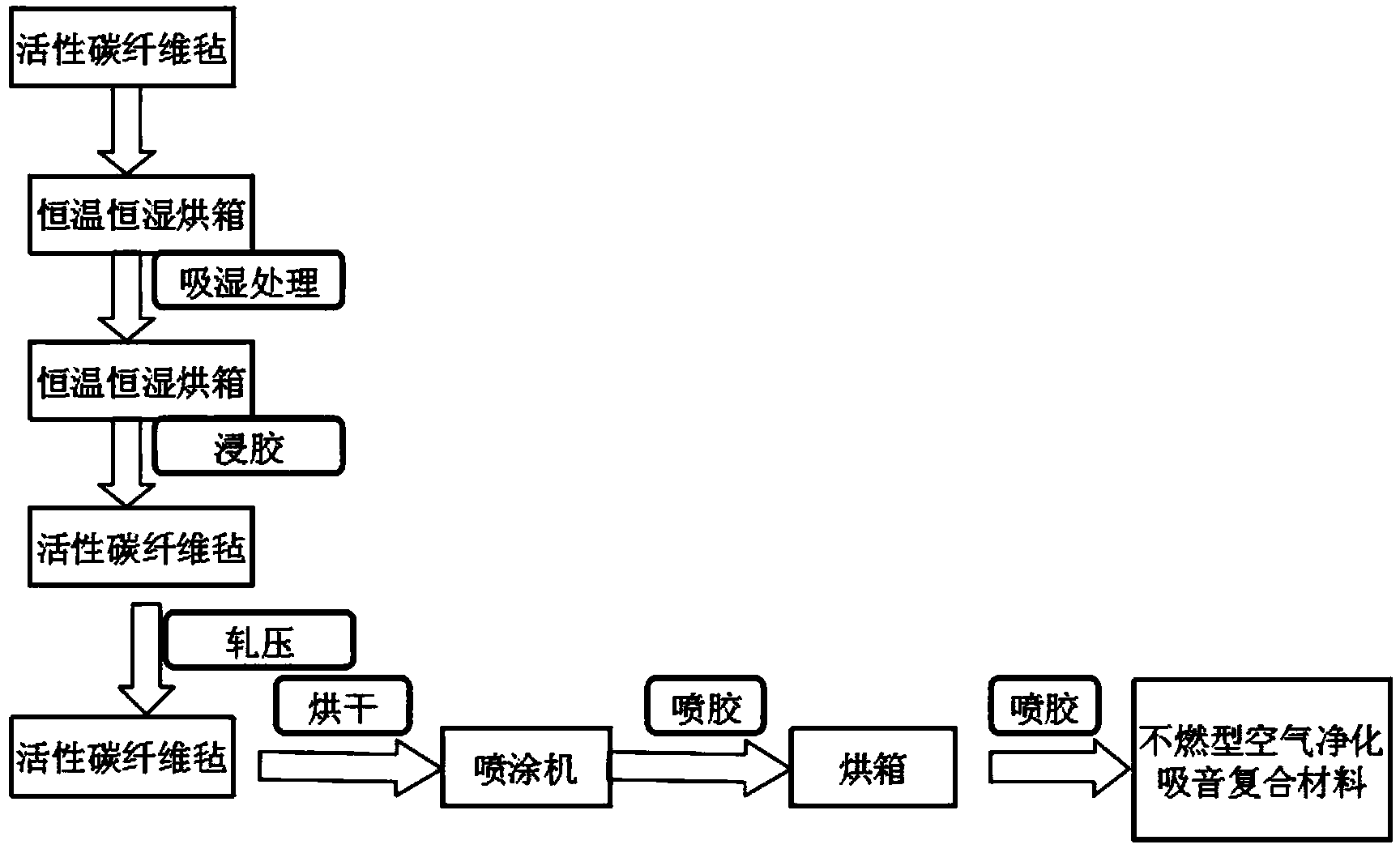

Method used

Image

Examples

Embodiment 1

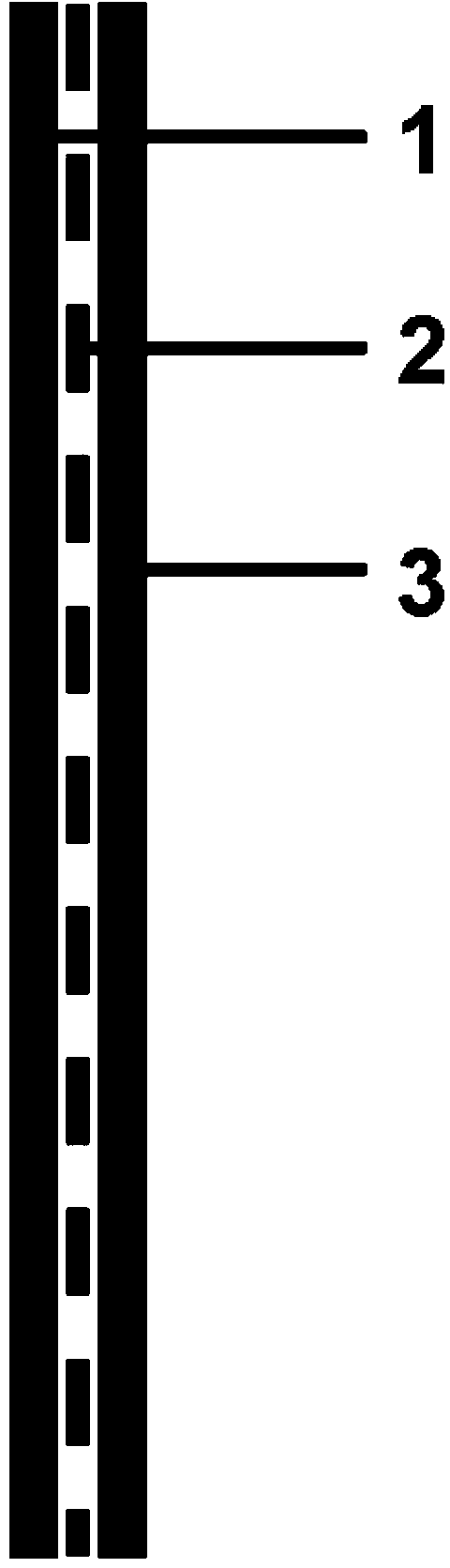

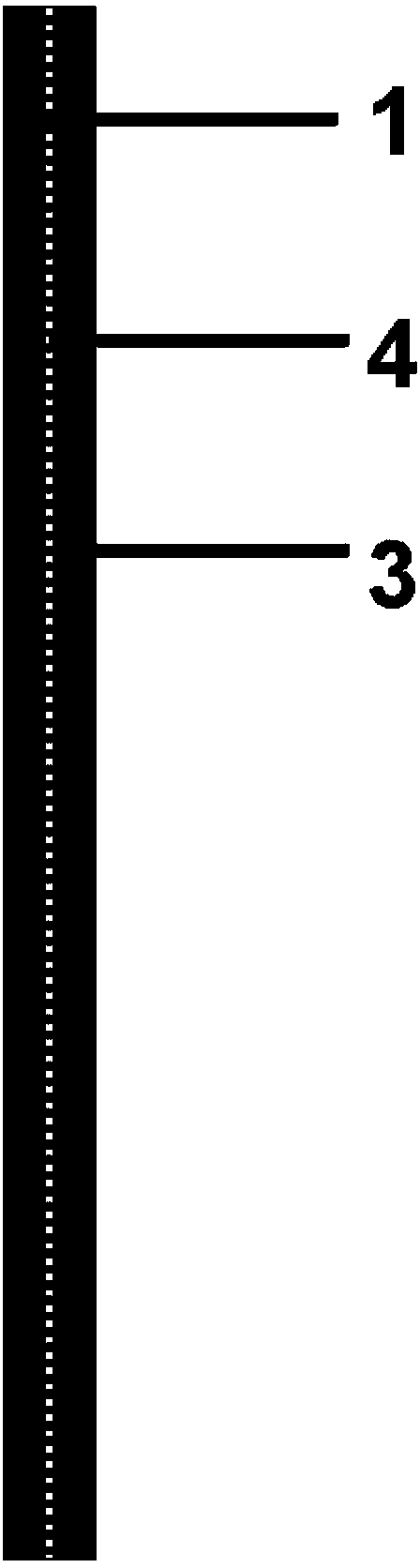

[0026] Embodiment 1: the activated carbon fiber felt is absorbed moisture for 3h at 30°C and 60% humidity, and in the mixed solution of 0.4% aqueous acrylic acid ester and 0.5% sodium silicate, mix the nanometer TiO of mixed solution gross mass 0.1% Photocatalyst, Use the mixed solution containing photocatalyst as the impregnating solution to impregnate the activated carbon fiber, roll and press, the excess rate is 230%, and dry at 120°C for 3 hours to obtain the impregnated mat; do waterproof treatment on one side of the impregnated felt, After drying at 100°C for 2 minutes, use a water-based acrylic adhesive with a glass transition temperature of -15°C and a solid content of 3% for surface spraying. The amount of spraying glue is 10g / m2. figure 2 , to obtain the glue-sprayed felt, and dry it with the sandwich structure of "sprayed glue-treated felt-barbed wire-sprayed glue-treated felt" at a drying temperature of 120°C and a drying time of 2 hours to obtain a non-combustible...

Embodiment 2

[0027] Embodiment 2: the activated carbon fiber felt is absorbed moisture for 3h at 40°C and 70% humidity, and in the mixed solution of 0.3% aqueous acrylic acid ester and 0.6% sodium silicate, mix the nanometer TiO2 photocatalyst of 0.05% of the total mass of the mixed solution, Use the mixed solution containing photocatalyst as the impregnating liquid to impregnate the activated carbon fiber, roll it, and the excess rate is 200%, and dry it at 100°C for 3 hours to obtain the impregnated mat; do waterproof treatment on one side of the impregnated felt, After drying at 130°C for 5 minutes, use a water-based acrylic adhesive with a glass transition temperature of 0°C and a solid content of 4% for surface spraying. The amount of spraying glue is 15g / m2. figure 2 , to obtain the glue-sprayed felt, and dry it with the sandwich structure of "sprayed glue-treated felt-barbed wire-sprayed glue-treated felt" at a drying temperature of 130°C and a drying time of 1 hour to obtain a non-...

Embodiment 3

[0028] Embodiment 3: the active carbon fiber mat absorbs moisture for 5h at 60°C and 70% humidity, and mixes the nanometer TiO2 photocatalyst with 0.15% of the total mass of the mixed solution in the mixed solution of 0.2% water-based acrylate and 0.4% sodium silicate. The mixed liquid containing photocatalyst is used as the impregnating liquid to impregnate the active carbon fiber, rolling and pressing, the excess rate is 300%, and after drying at 130°C for 2 hours, the impregnated felt is obtained; one side of the impregnated felt is waterproofed, and after Dry at 130°C for 1 minute, then use a water-based acrylic adhesive with a glass transition temperature of -25°C and a solid content of 2% for surface spraying, and the amount of spraying glue is 20g / m 2 , see eg figure 2 , to obtain the glue-sprayed felt, and dry it with the sandwich structure of "sprayed glue-treated felt-barbed wire-sprayed glue-treated felt" at a drying temperature of 150°C and a drying time of 1 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com