In-situ visualization method for cavitation behavior of fused brazing filler metal in solid liquid interface in ultrasonic-assisted brazing

A technology of solid-liquid interface and molten solder, applied in welding equipment, metal processing equipment, manufacturing tools, etc., to achieve the effect of optimizing technology and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

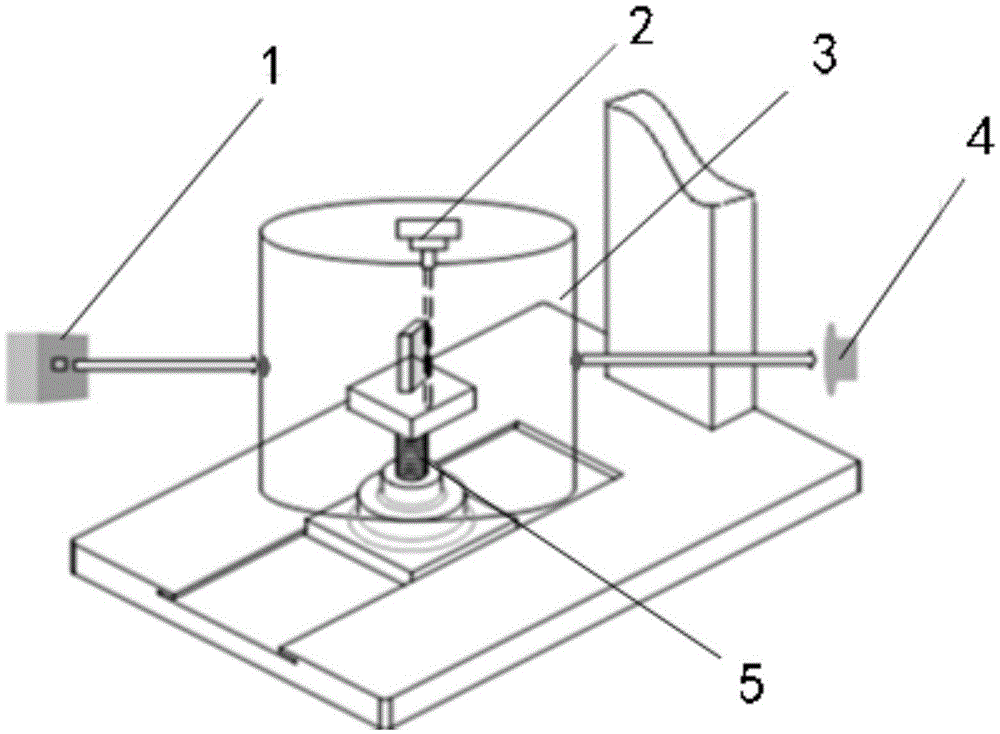

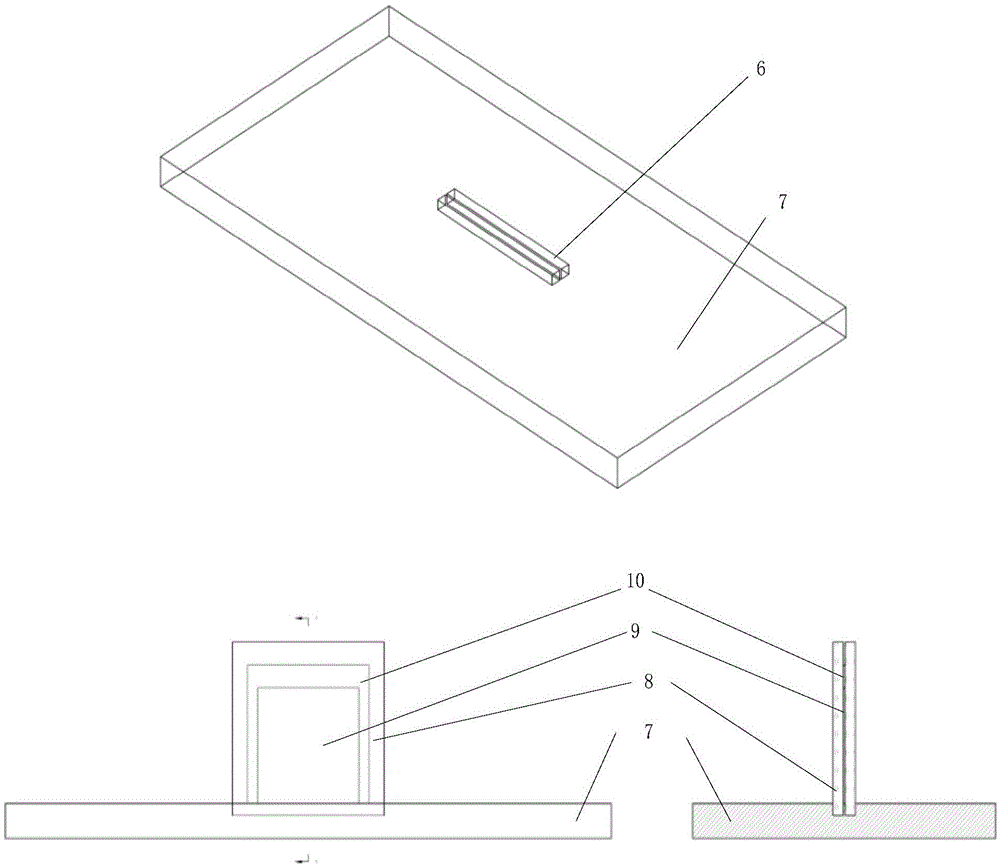

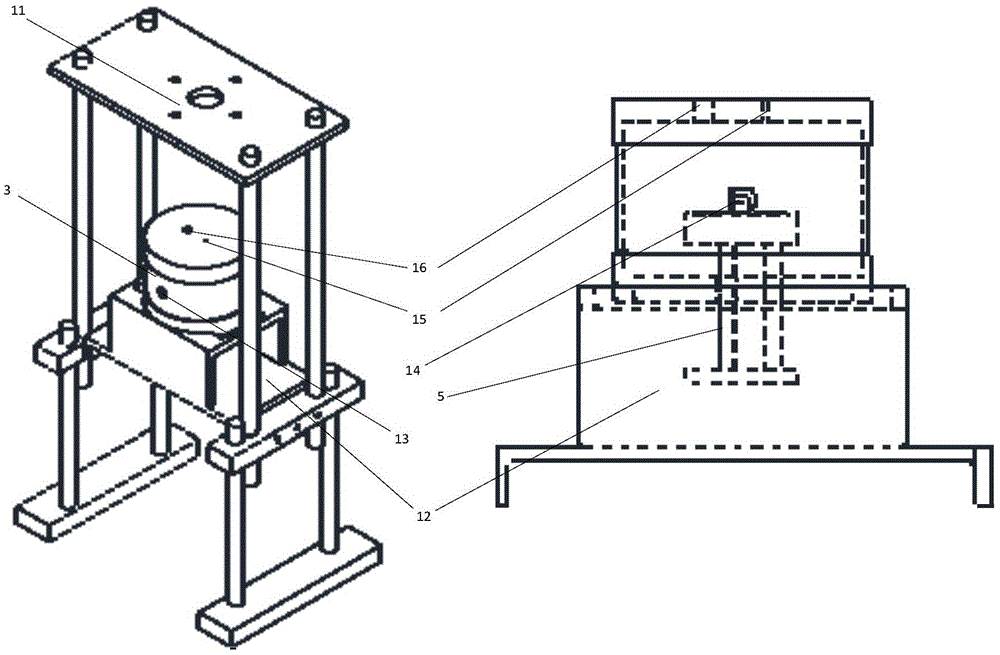

Method used

Image

Examples

Embodiment 1

[0052] Using the above-mentioned synchrotron radiation imaging method and device, Al-11.5Si-1.5Mg solder alloy (melting point 585°C) was selected to make an ultra-thin sample of 200 μm by sandpaper grinding, and TC4 titanium alloy was selected as the base material, and the test temperature was set At 610°C, observe the generation and distribution of bubbles at the solid-liquid interface during the heating process and after ultrasonic application. Among them, a) there are no bubbles at 0°C, and there are gaps at the interface; b) bubbles appear at 610°C when ultrasonic is applied for 10s; c) bubbles become larger and gaps decrease at 620°C when ultrasonic is applied for 60s. Such as Figure 4 Shown:

Embodiment 2

[0054] Using the above-mentioned synchrotron radiation imaging method and device, select Al-11.5Si-1.5Mg solder alloy (melting point 585°C), grind it with sandpaper to make an ultra-thin sample of 200 μm, select 1060 aluminum alloy as the base material, and set the test temperature At 600°C, observe the generation and distribution of bubbles at the solid-liquid interface during the heating process and after ultrasonic application. Among them, a) there are no bubbles at 0°C, and there are gaps at the interface; b) bubbles appear at 600°C when ultrasonic is applied for 10s; c) bubbles become larger when ultrasonic is applied for 50s at 610°C. Such as Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com