Built-in cone type filter bag

A filter bag and cone-type technology, applied in the field of inlaid cone-type filter bags, can solve the problems of high operating cost, large amount of compressed gas for cleaning dust, and increased investment, so as to reduce manufacturing costs, improve cleaning efficiency, increase The effect of a large filter area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

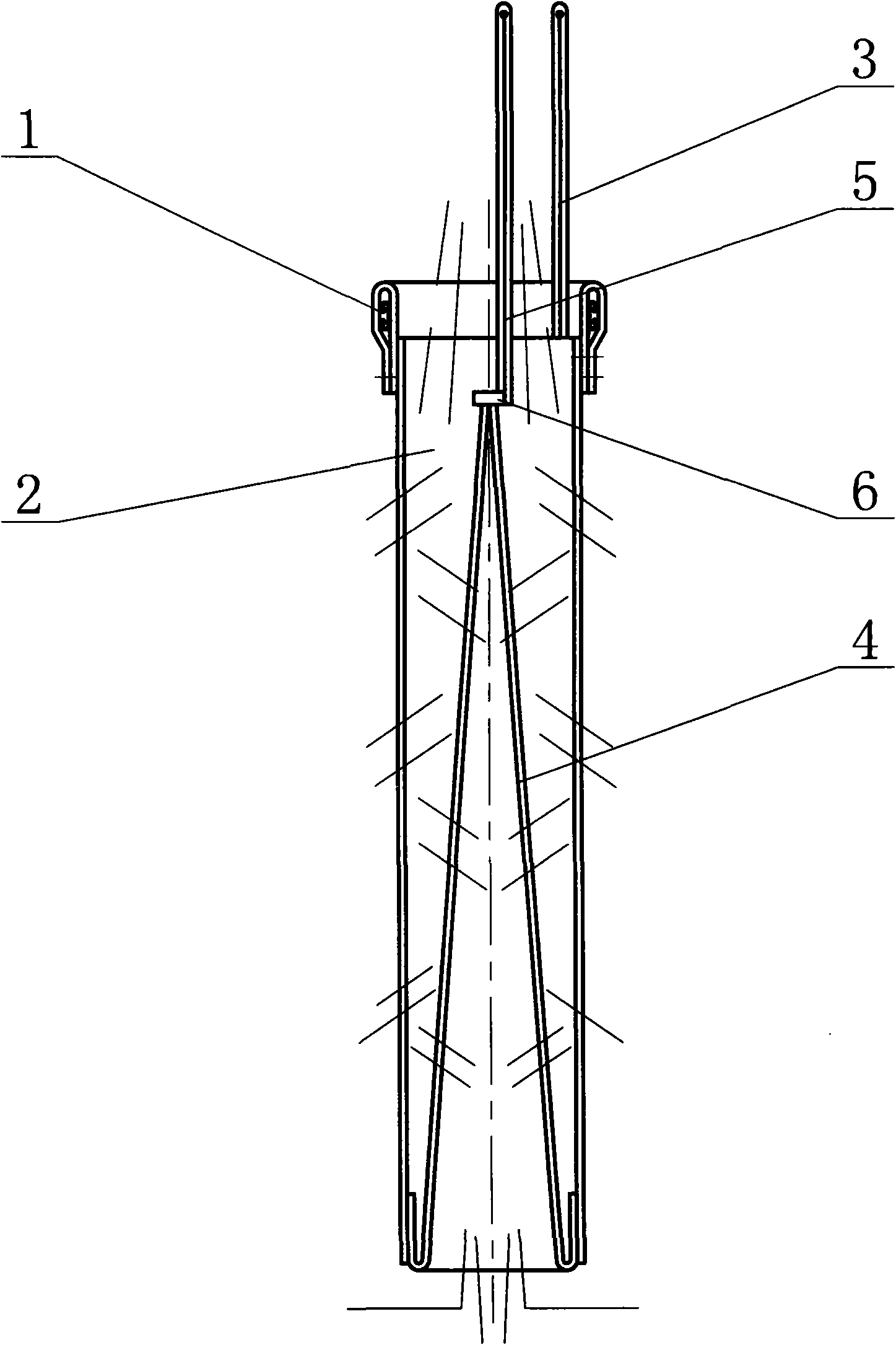

[0011] Please refer to Figure 1 , the inner tapered filter bag of the present invention comprises a pocket mouth 1, a straight bag 2, an outer drawstring 3, a cone pocket 4, an inner drawstring 5, and a cone pocket buckle 6, and the outer drawstring 3 is sewn on the inner side of the pocket mouth 1, The mouth 1 is sewn on one end of the straight bag 2, the straight bag 2 and the cone bag 4 have no bottom, the other end of the straight bag 2 is sewn to the cone bottom of the cone bag 4 to form an opening, the cone bag 4 is inside the straight bag 2, and the inside The drawstring 5 is sewn with the cone top of the cone bag 4, and the cone bag button 6 is sewn with the cone top of the cone bag 4. The inner cone filter bag is stitched except for the pocket 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com