Comprehensive gas control method for fully mechanized caving face in three soft and extra thick coal seams

A fully-mechanized caving face and extra-thick coal seam technology, which is applied to gas discharge, earthwork drilling, mining equipment, etc., can solve the problems of gas affecting production safety and achieve the effect of ensuring safe production and production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

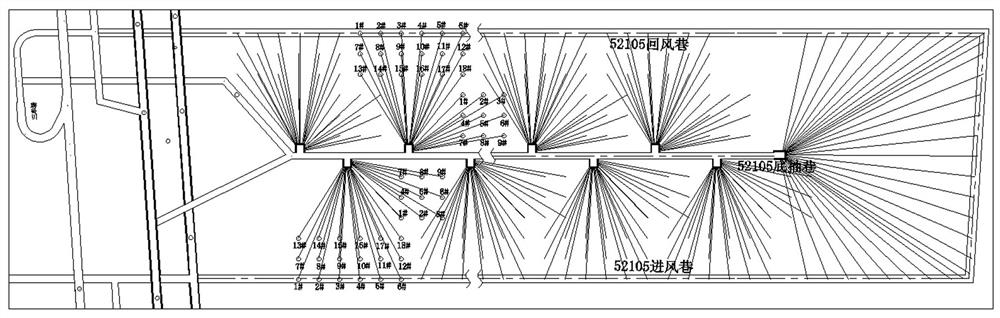

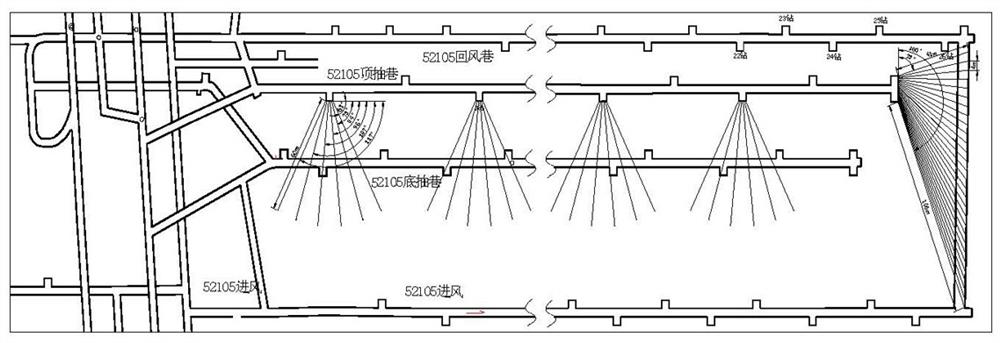

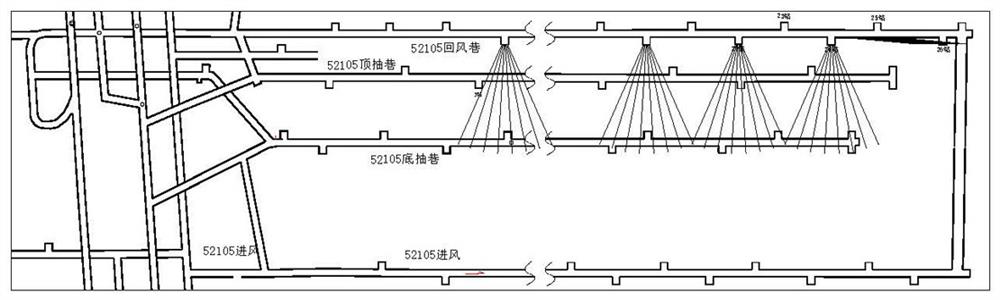

Image

Examples

Embodiment 1

[0024] In this example, the present embodiment is taken by Datong Coal Mine Group Co., Ltd. Xuangang Coal and Electric Coal Mine, Jiaojiazhai Coal Mine:

[0025] Jiaojiazhai mine 521 mining area is high gas production area, the work surface is arranged in the 5 # coal seam, 5 # coal seam is one of the main coal mining layers of our mine, the mine 5 # coal seam thickness is about 9.5-13.9 meters, an average of 11 meters The coal is soft, easy to break, and the Pu's factor is 0.2-0.4.

[0026] Due to the softness of the 5 # coal seam, with the deepening of the depth, the pressure is getting bigger and larger, the gas deposit drilling hole in the coal seam is serious and the hole is difficult, alone rely on the coal seam of water. Gas has Unable to solve the 52105 working surface gas problem.

[0027] In order to ensure the gas problem during the 52105 working surface, ensure the safety production of the work surface, in the following method, gas comprehensive management:

[0028] (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com