Brush type electrostatic dust remover

A technology of dust collector and electrostatic brush, which is applied in the direction of external electrostatic separator, electrostatic separation, electrostatic effect separation, etc. The cumbersome ash work, the effect of avoiding dust accumulation and improving the work progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

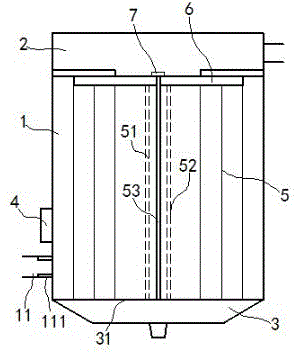

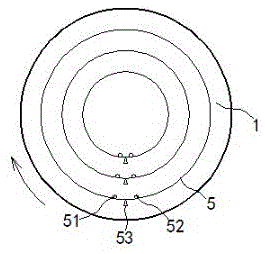

[0015] exist figure 1 , figure 2 In the shown embodiment, the electrostatic brush dust collector includes a dust removal chamber 1, a clean chamber 2 and an ash bucket 3; A dust collection screen 31 is installed between the bucket 3 and the dust removal chamber 1; an air inlet 11 and an exhaust port are respectively provided on the dust removal chamber 1 and the purification chamber 2; a discharge sheet is installed at the air inlet 11 111, the discharge sheet 111 is electrically connected to one pole of the electrostatic generator 4; an electrostatic net cylinder 5 is vertically installed inside the dust removal chamber 1, and the electrostatic net cylinder 5 is driven by a drive turntable installed on the top of the dust removal chamber 1 6 drives the rotation; the upper end of the electrostatic mesh cylinder 5 is connected to the clean chamber 2, and a screen is installed between the clean chamber 2 and the electrostatic mesh cylinder 5; the lower end of the electrostatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com