Meat mincing device used for can production

A technology for grinding and canning meat, which is applied in the field of meat grinding devices for canned food production. It can solve the problems of prolonging the time of grinding meat, low efficiency of mixing seasoning and meat, and long time of grinding meat, so as to reduce the time of grinding meat and improve the stirring time. Efficiency, effect of preventing gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further detailed explanation through specific implementation mode below:

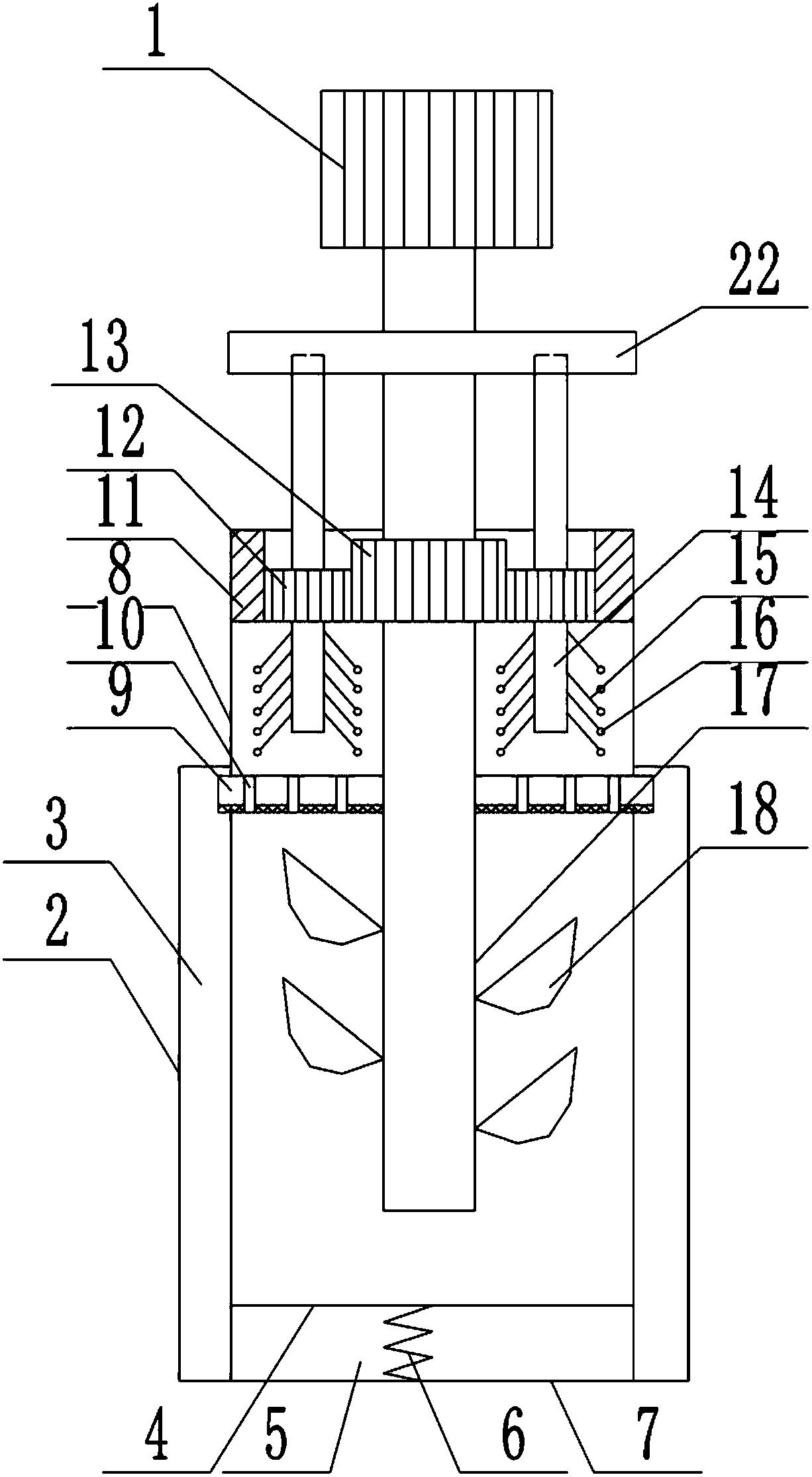

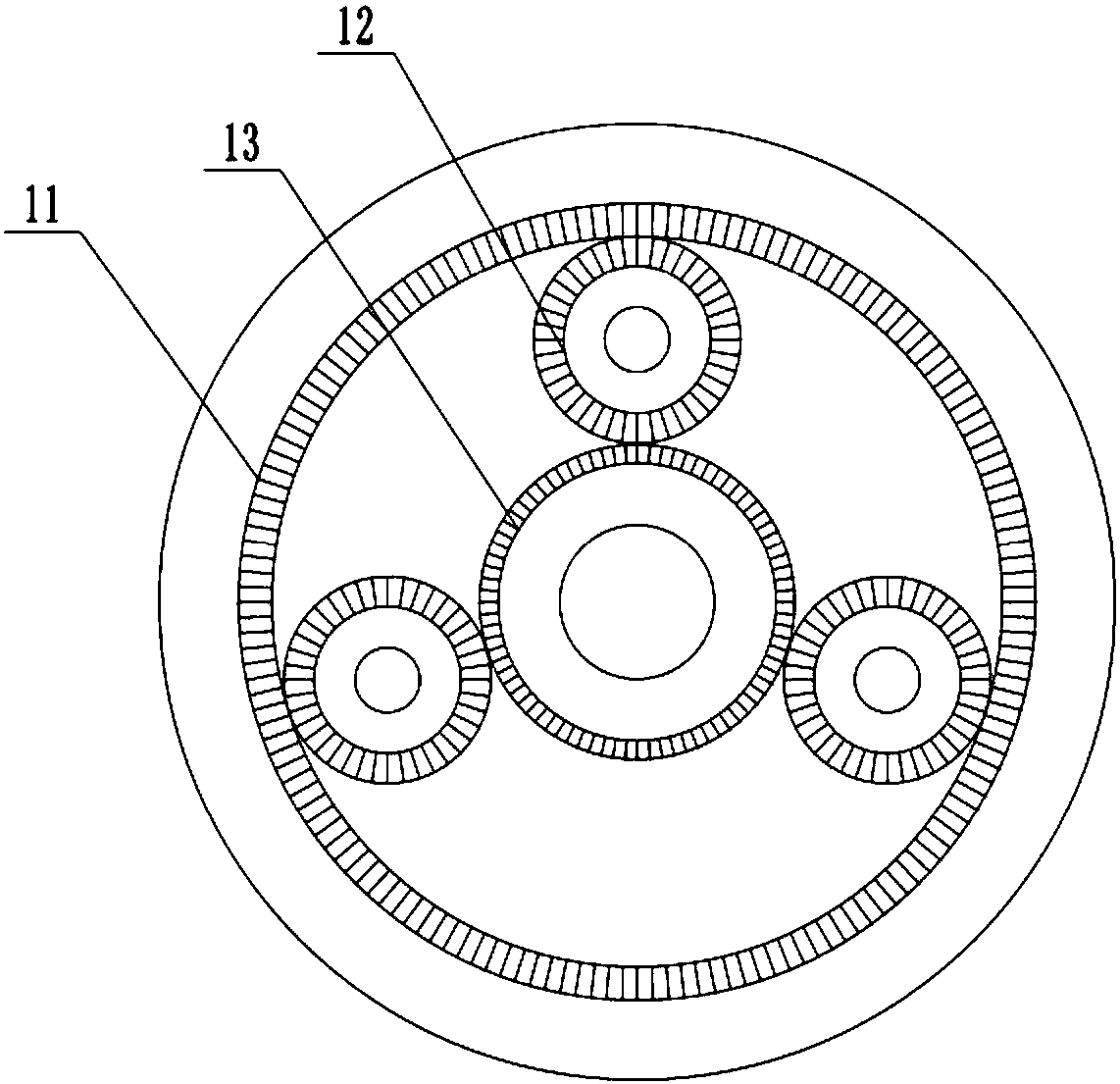

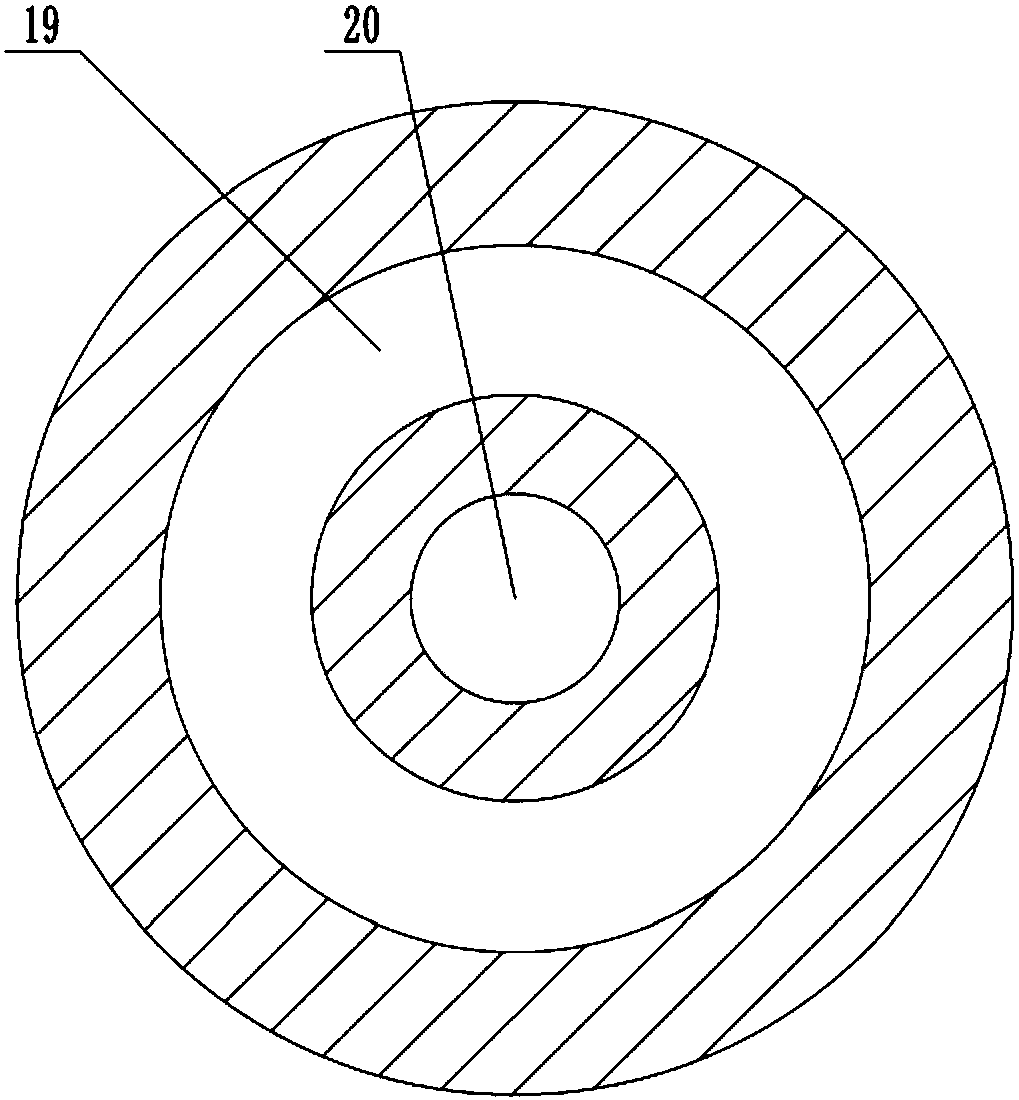

[0017] The reference signs in the drawings of the description include: motor 1, meat grinding cylinder 2, ventilation cavity 3, top plate 4, compression part 5, spring 6, bottom plate 7, material box 8, discharge part 9, discharge hole 10, inner Gear 11, external gear 12, main gear 13, stirring shaft 14, pull rope 15, pendulum 16, meat grinder shaft 17, blade 18, ring groove 19, first circular groove 20, second circular groove 21, fixed plate 22 .

[0018] The embodiment is basically as attached figure 1 Shown: a kind of meat grinder that is used for the production of canned food, comprises meat grinder tube 2 and meat grinder shaft 17, and meat grinder tube 2 is made of glass, is provided with blade 18 on the meat grinder shaft 17, and the bottom of meat grinder shaft 17 The end is located in the meat grinding cylinder 2, the top of the meat grinding shaft 17 is connected with a motor 1, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com