Sludge dewatering and press-filtering device

A technology for sludge dehydration and equipment, which is applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/thickened sludge treatment, etc. It can solve problems such as inability to separate, sludge dehydration extrusion, blockage, etc. , to achieve the effect of low cost, good desliming technical effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

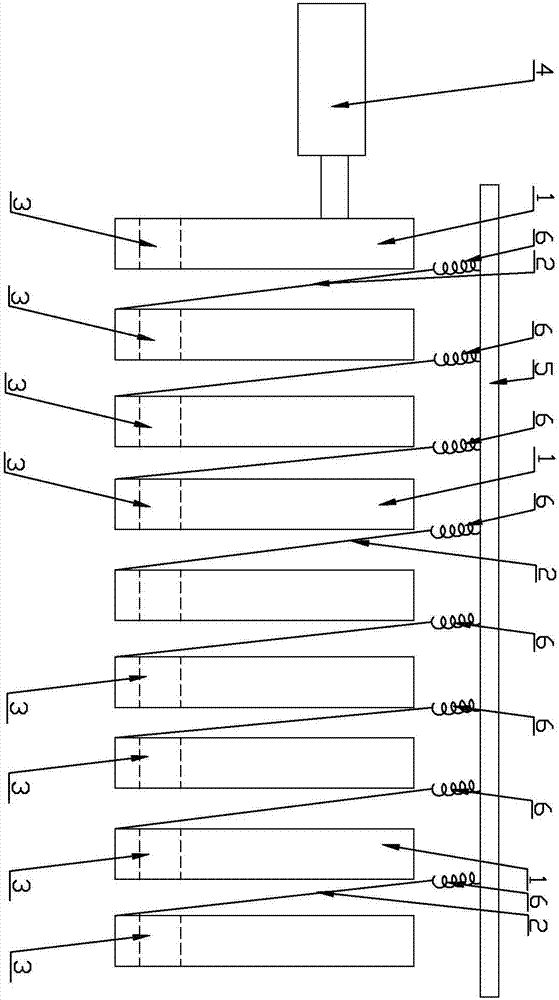

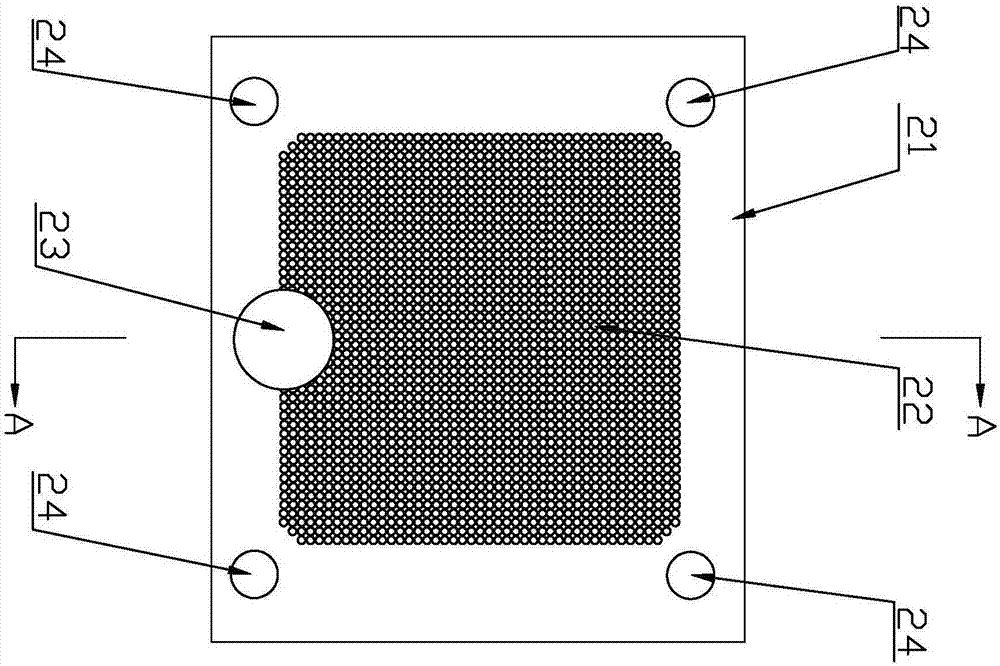

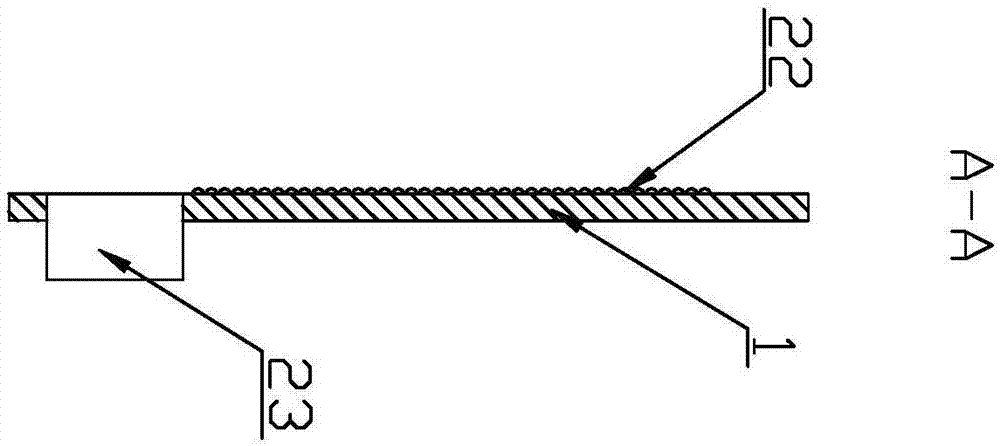

[0022] refer to Figure 1 to Figure 4 , the present invention is a sludge dewatering filter press equipment, comprising a filter press box, a plurality of tympanum plates 1 arranged side by side on the filter press box and a driving motor 4 for pushing and pulling each tympanum plate 1 to move, between adjacent tympanum plates 1 The filter membrane 2 is provided, and also includes a fixed frame 5 and a vibrator arranged on the fixed frame 5 for vibrating or pulling each filter membrane 2, and the lower end of each tympanic membrane plate 1 is also provided with a water hole through the tympanic membrane plate 1 3. The upper end of each filter membrane 2 is connected to the vibrator, and the lower end of each filter membrane 2 is fixedly arranged on the tympanic membrane 1 at the lower part of the water hole 3 .

[0023] Through the setting of the vibrator and the water hole 3, when the tympanic membranes 1 are squeezed and the sludge is separated, the vibrator pulls or shakes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com