Solid waste drying treatment system and treatment process

A solid waste and treatment system technology, applied in the direction of dry goods processing, dry solid materials, progressive dryers, etc., can solve the problems of difficulty in removal, processing effects, and long natural drying time, so as to reduce the footprint. The effect of space, shortening working time and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

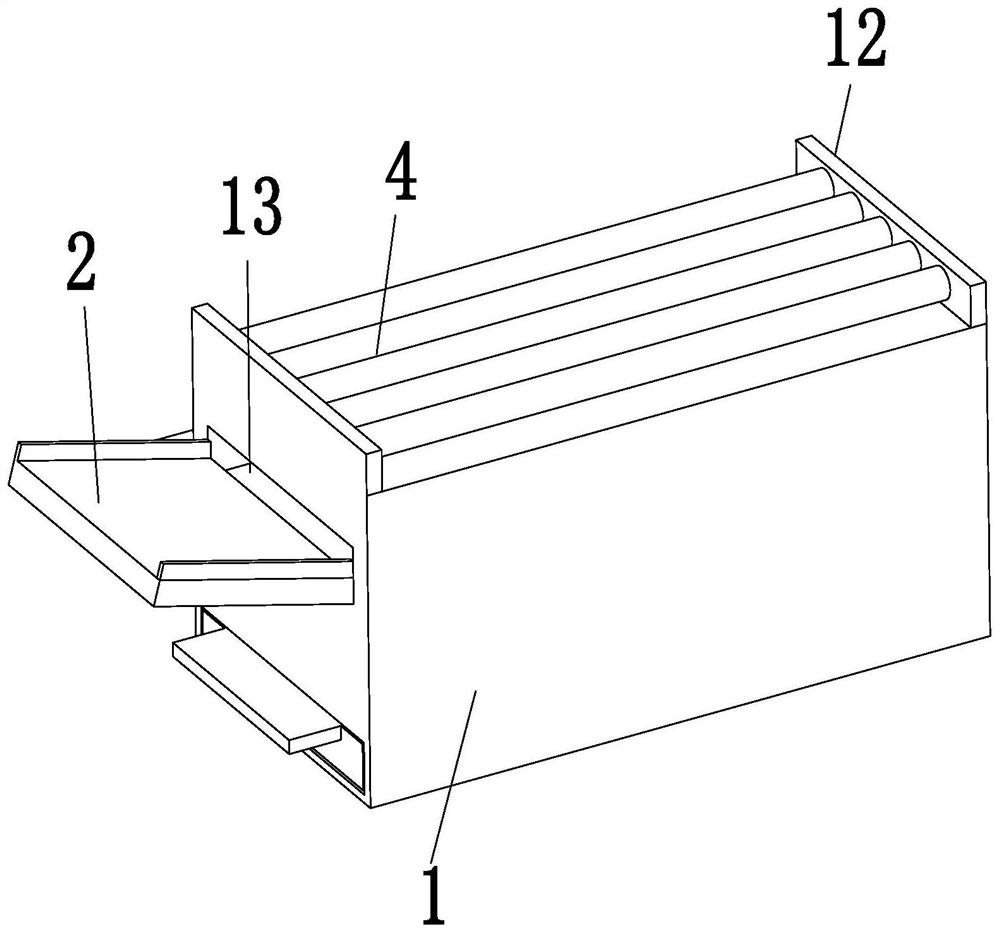

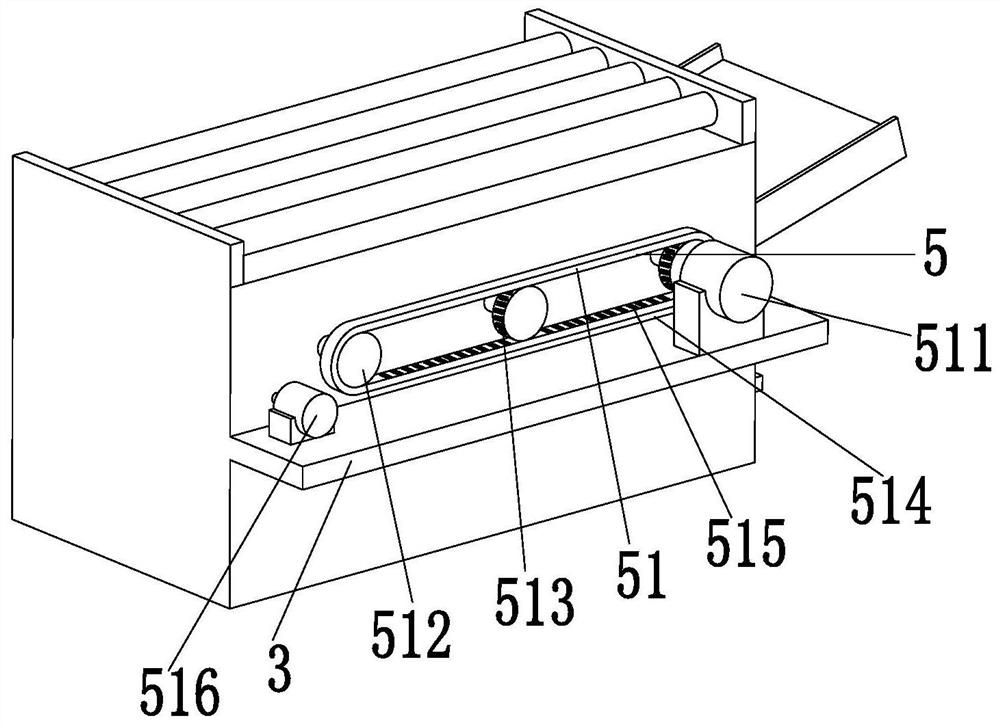

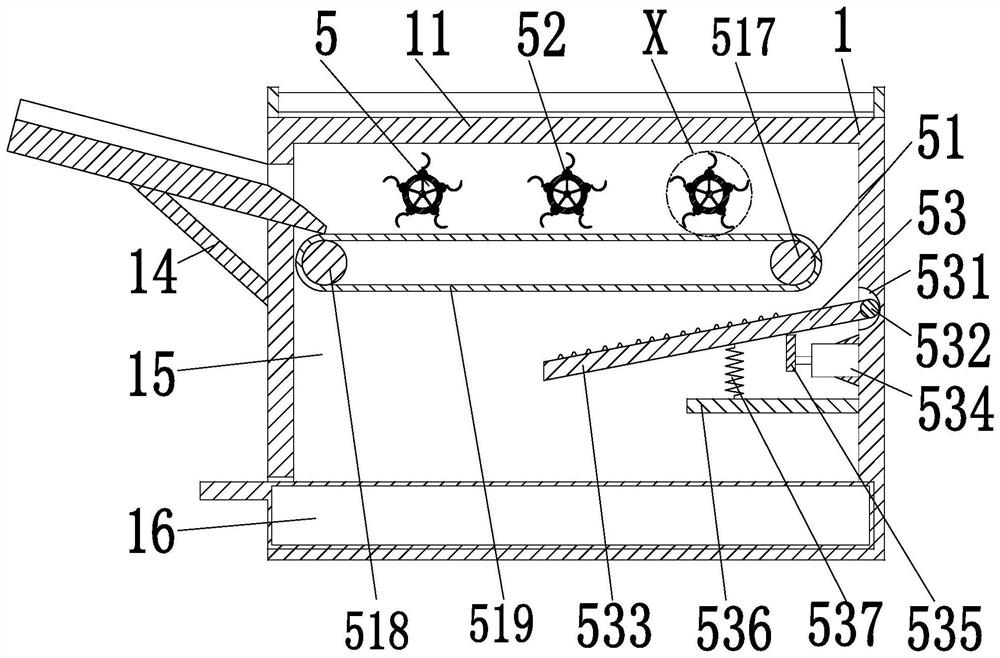

[0034] Such as Figure 1 to Figure 6 As shown, a solid waste drying processing system includes an installation frame 1, a feed plate 2, an installation plate 3, a heating rod 4 and a drying device 5, and a feed plate is fixed on the outer wall of the left end of the installation frame 1 2. The front and rear ends of the feed plate 2 are symmetrically installed with limit baffles 21 to prevent the solid waste from sliding away from the feed plate 2 during the sliding process; the installation frame 1 is equipped with a mounting plate 3 , The upper end of the installation frame 1 is evenly provided with heating rods 4, and the interior of the installation frame 1 is provided with a drying device 5.

[0035]Described installation frame 1 comprises ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com