Rice drying equipment

A technology for drying equipment and rice, which is applied in drying, drying machines, lighting and heating equipment, etc. It can solve the problems of uneven distribution of rice, high water content of rice, steamed outer layer of rice, etc., and achieve the thickness of rice accumulation Consistent, evenly distributed, quality-assured results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

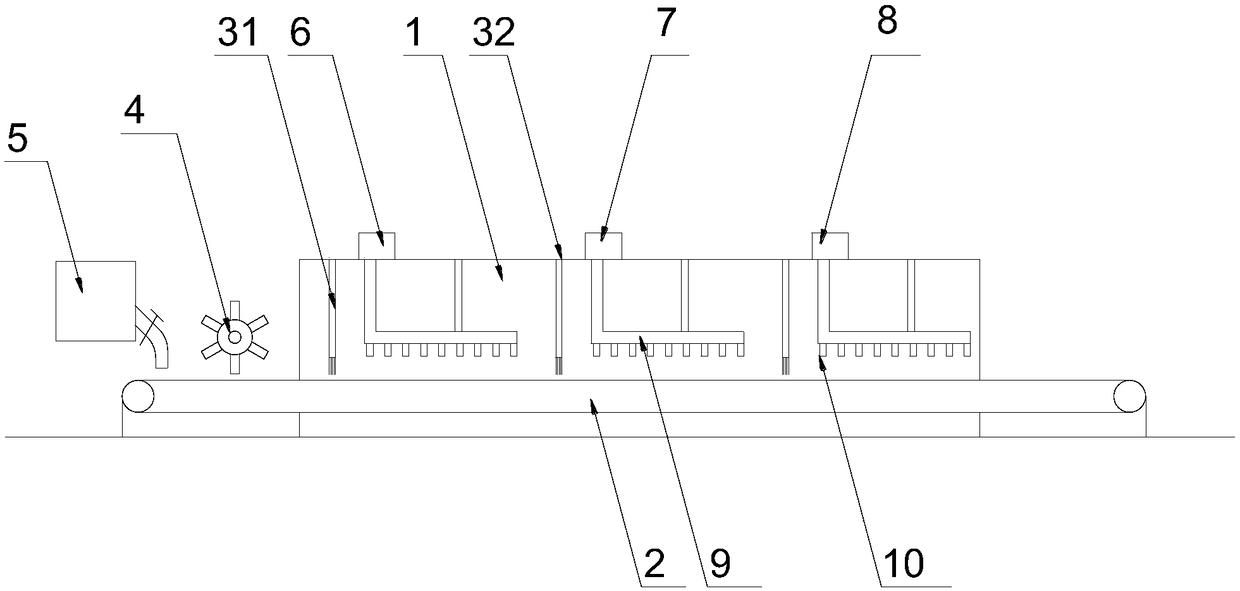

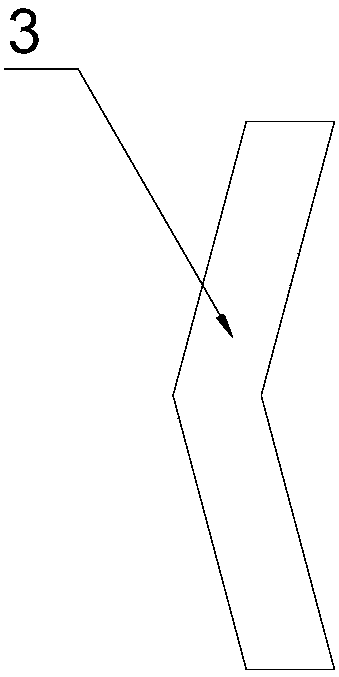

[0019] Such as Figure 1-2 as shown, figure 1 It is a structural schematic diagram of a kind of rice drying equipment proposed by the present invention, figure 2 It is a top view of the baffle in the rice drying equipment proposed by the present invention.

[0020] refer to Figure 1-2 , a kind of rice drying equipment that the present invention proposes, comprises drying chamber 1, conveyor belt 2, baffle plate 3, rotating roller 4, feeder 5, fan 6, first hot air blower 7, second hot air blower 8, air duct 9 and the air spray head 10; Wherein, the baffle plate 3 comprises the first baffle plate 31, the second baffle plate 32 and the third baffle plate 33;

[0021] A conveyor belt 2 is arranged inside the drying bin 1, and the two ends of the conveyor belt 2 protrude from the outside of the drying bin 1; There are rotating rollers 4, and the rotating rollers 4 are located between the feeder 1 and the drying bin 1; the outer circumference of the rotating rollers 4 is evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com