Control method of ball mill

A control method and ball mill technology, applied in the field of ball mill control, can solve problems such as untimely lubrication of the ball mill, material blockage at the inlet and outlet of the ball mill, damage to equipment, etc., and achieve the effects of preventing material blockage, preventing material inlet port blockage, and optimizing the program

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

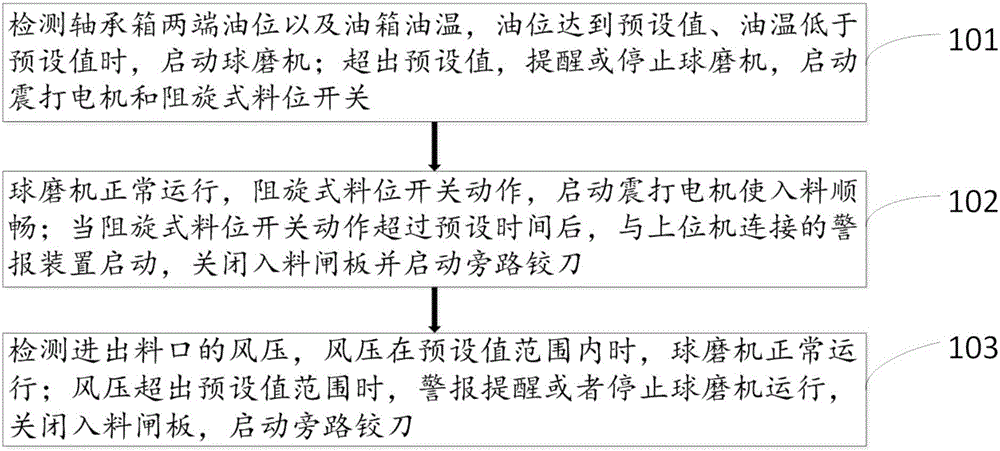

[0025] like figure 1 As shown, a control method of a ball mill comprises the following steps:

[0026] Step 1) Detect the oil level at both ends of the bearing box of the ball mill through the oil level detection device, and the temperature detection device detects the oil temperature of the oil tank. When the oil level reaches a preset value and the oil temperature is lower than the preset temperature, the upper computer controls the ball mill to start; When the oil level or oil temperature exceeds the preset value range, the upper computer interface will remind or directly control the stop of the ball mill, and start the vibrating motor and the anti-rotary material level switch located at the material inlet of the ball mill.

[0027] When the oil level at both ends of the bearing box is above 30%, and the temperature of the oil tank is lower than 80°C, the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com