Energy accumulating pulse micro feeding system for precise fine abrasive water jet

A technology of abrasive water jet and feeding system, which is applied in the direction of grinding/polishing equipment, etc., can solve problems such as unstable feeding, achieve the effects of improving processing quality, preventing accumulation and agglomeration, and eliminating interruption of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

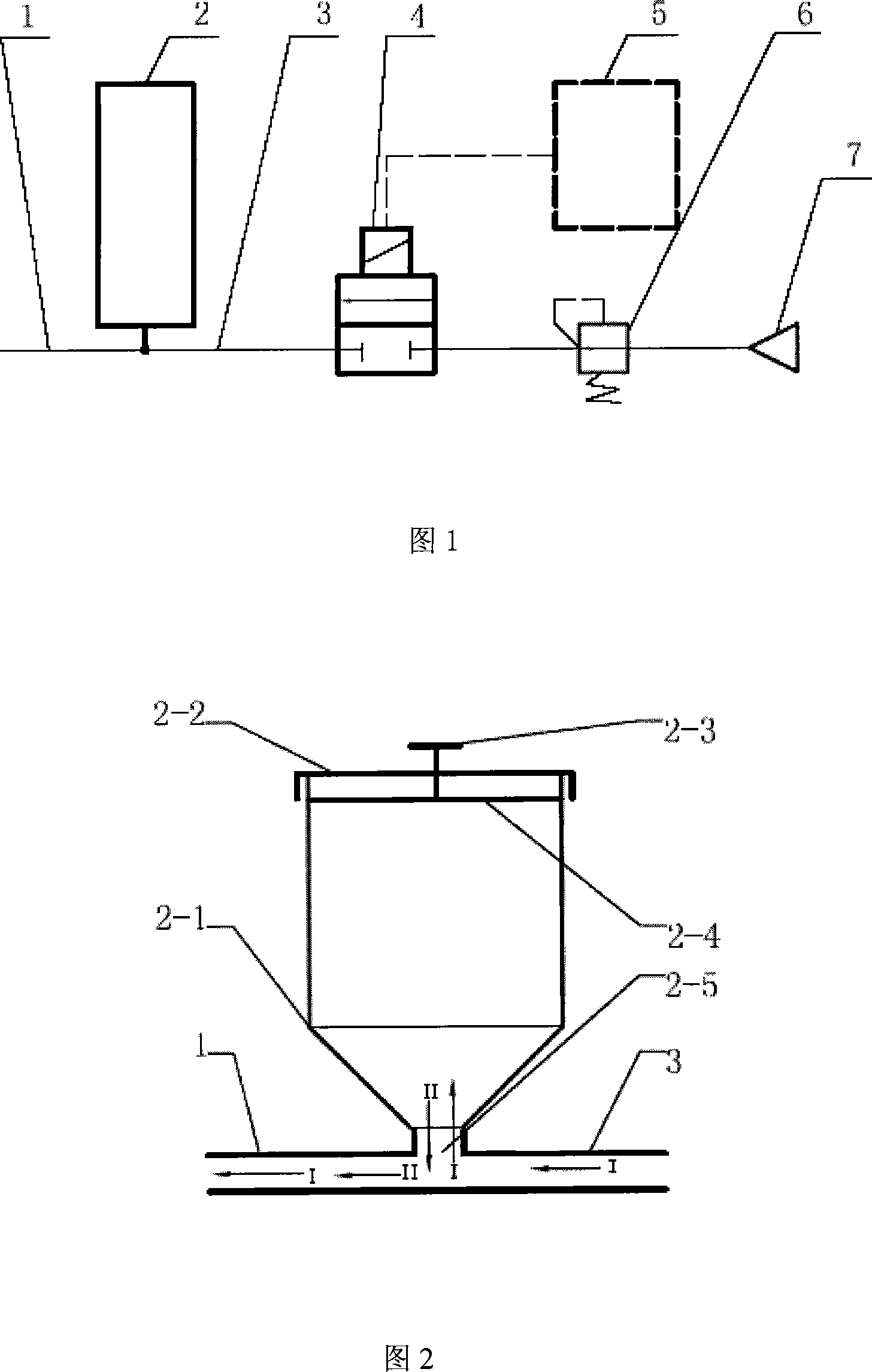

[0021] Describe the implementation process of the present invention in detail in conjunction with accompanying drawing, as shown in Fig. 1, Fig. 2:

[0022] The precision micro-abrasive water jet energy-storage pulse micro-feeding system is mainly composed of a feed pipe 1, an energy-storage silo 2, an air supply pipe 3, a high-frequency switch valve 4, a frequency conversion control circuit 5, a pressure regulating valve 6 and a low-pressure air source 7 and other components. The air inlet of the pressure regulating valve 6 is connected to the air source 7 through a pipeline, the air outlet of the pressure regulating valve 6 is connected to the air inlet of the high-frequency switching valve 4 through a pipeline, and the circuit of the high-frequency switching valve 4 is connected to the frequency conversion control circuit 5-phase connection, the air outlet of the high-frequency switching valve 4 is connected to the discharge port of the energy storage type silo and connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com