Supply system for suspension smelting furnace

A suspension smelting furnace and reaction furnace technology, applied in furnaces, vertical furnaces, furnace components, etc., can solve the problems of heavy structure and large investment in the intermediate silo, and achieve the effect of eliminating material supply interruption, low investment and light structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

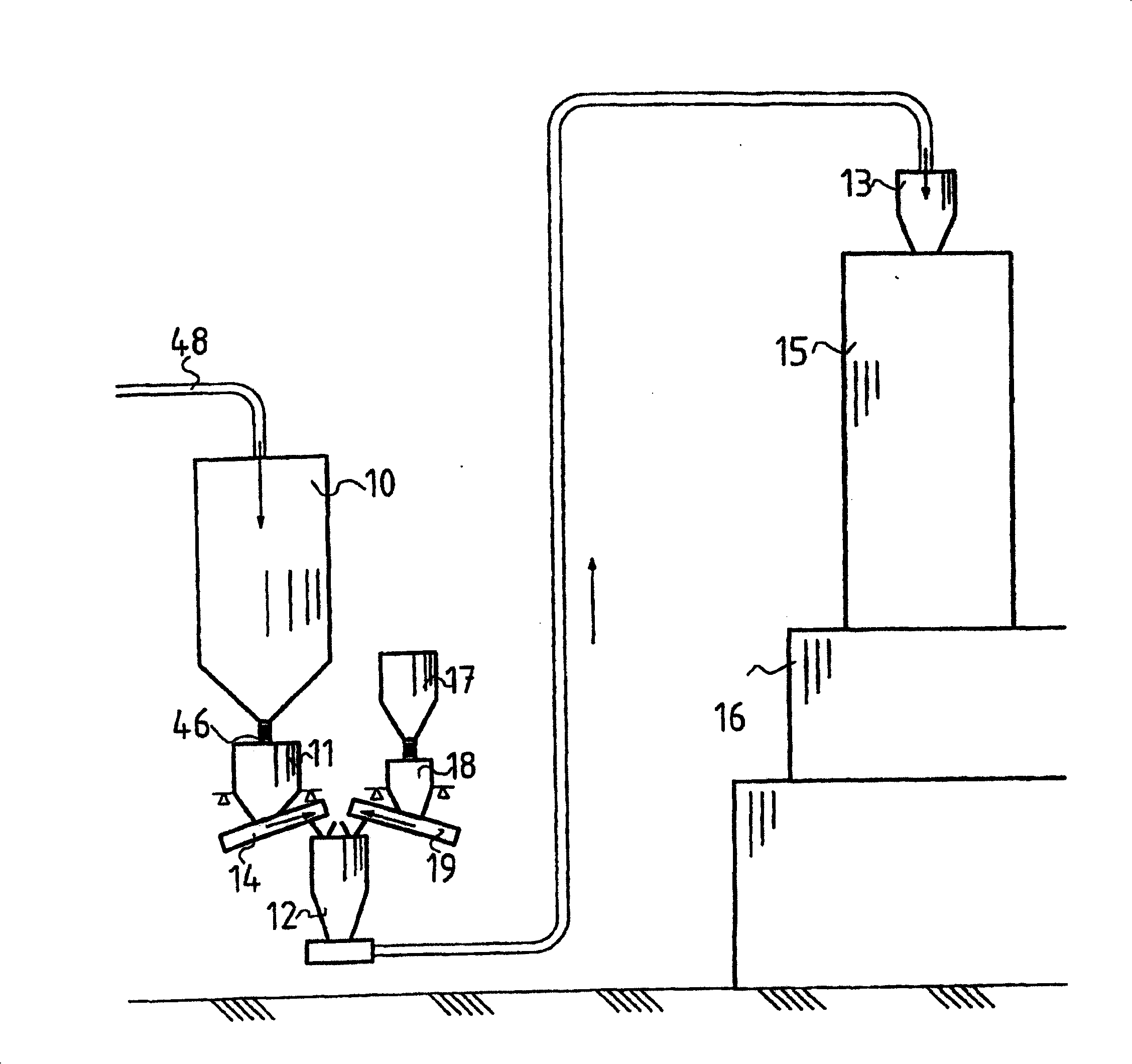

[0020] exist figure 1 In the shown arrangement, a dry mixture of metal concentrate and flux is fed into silo 10 via conduit 48 . The outlet 46 of the silo is adapted to convey the concentrate mixture into the loss-in-weight feed controller 11 . Screw conveyor 14 conveys the precise mass flow of concentrate mixture into pneumatic conveyor 12, which is a dilute phase pneumatic conveyor. A pneumatic conveyor 12 conveys the concentrate mixture upwards to a concentrate nozzle 13 of a suspension smelting furnace 16 . Such as figure 1 As shown, the outlet 46 of the silo 10 is substantially lower than the top of the reaction shaft 15 and the concentrate nozzle 13 . The soot is sent into the feed bin 17. The feed rate of concentrate mixture and soot must be carefully controlled. Thus, the soot is fed into a feed rate controller 18 which conveys a controlled mass flow of soot into the pneumatic conveyor 12 via the screw conveyor 19 . The flow of concentrate mixture and soot is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com