Heat carrier destructive distillation system for coal and method thereof

A carrier and dry distillation technology, which is applied in the direction of direct heating dry distillation, special form dry distillation, petroleum industry, etc., can solve the problems of unavailable semi-coke products, no use value, low thermal efficiency, etc., to reduce dry distillation time and increase heat Utilization rate, full combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

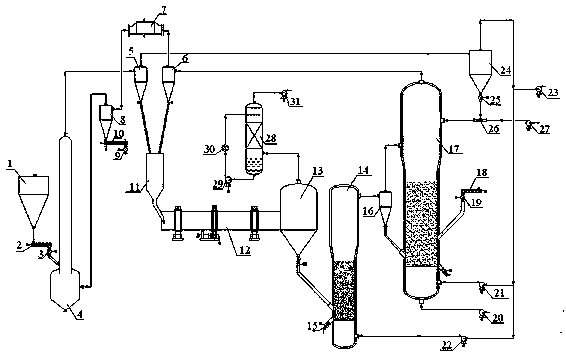

[0037] like figure 1 As shown, a heat carrier carbonization system for coal includes a raw coal bunker 1 , an airflow dryer 4 , and a circulating fluidized bed hot blast stove 17 .

[0038] The bottom of the raw coal bunker 1 is equipped with a screw metering conveyor I2, which is connected to the airflow dryer 4 through the air lock valve I3; the top of the airflow dryer 4 is connected to a drying primary separator 5 through the pipeline I, one of which is The side is connected to the secondary cyclone separator 8 of the hot blast stove through the pipeline II; the top of the drying primary separator 5 is connected to the drying secondary separator 24 through the pipeline III, and the mixer 11 is connected to the bottom; the secondary cyclone separator of the hot blast stove The bottom of 8 is provided with a cooling paddle machine 10, one side of which is connected to the waste heat boiler 7 through a pipe IV; the top of the cooling paddle machine 10 is provided with a cooli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com