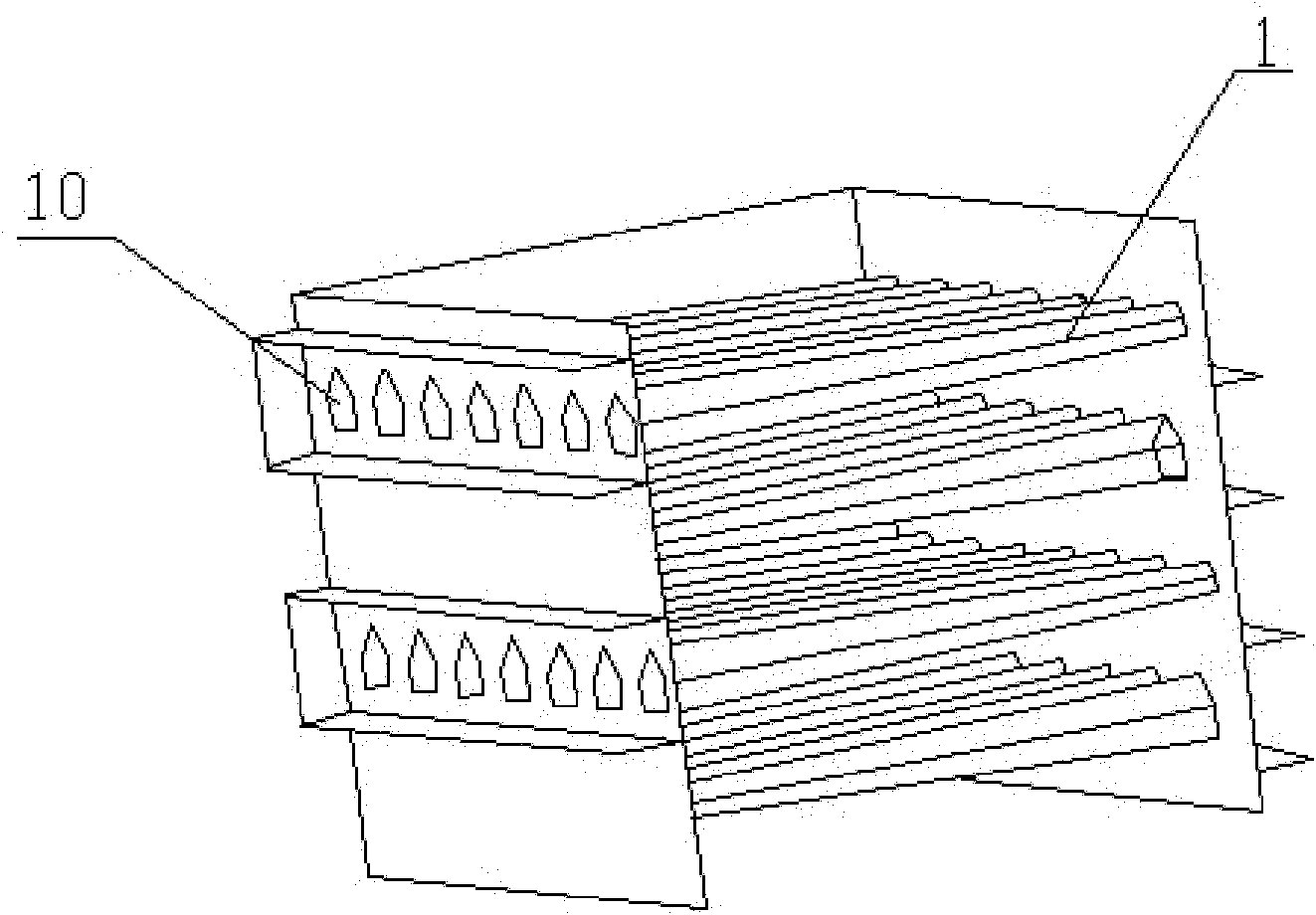

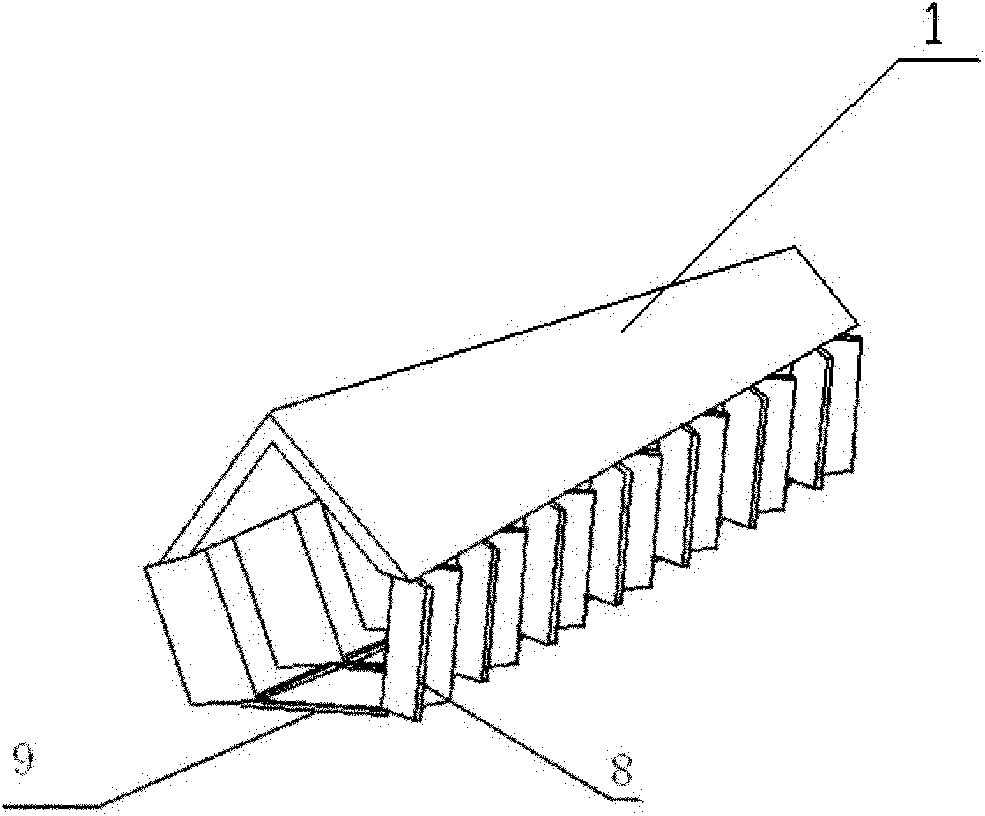

Efficient internal thermal type oil extraction device for powder oil shale and extraction method thereof

A technology of powder oil and internal heating, which is applied in the petroleum industry, special forms of dry distillation, direct heating dry distillation, etc., can solve the problems that restrict the development of oil shale oil extraction industry, low oil yield, low heat transfer efficiency, etc., and achieve Simple structure, reduced residence time, and improved carbonization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

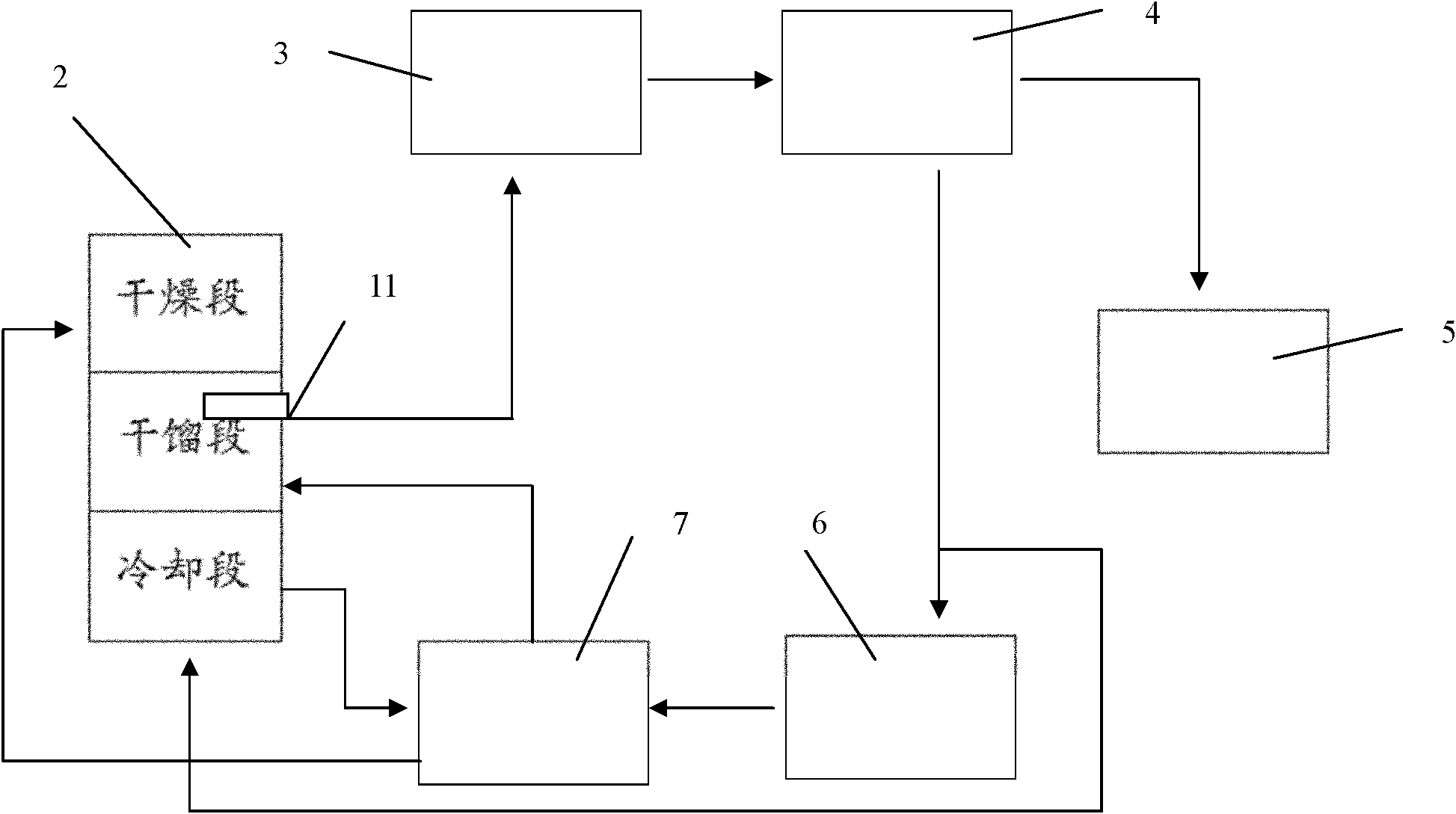

Embodiment 1

[0030] The raw material powdered oil shale enters the carbonization furnace from the feeding device, and after passing through the drying section, it directly exchanges heat with the hot gas gas at 550°C in the constant temperature carbonization section, heats the raw material powdered oil shale to 450°C, and produces Oil and gas: The decomposed oil and gas enter the condensing system from the top of the furnace through the oil and gas collection device to condense, and then cool down to liquid shale oil and enter the oil storage tank. The oil shale that has been fully carbonized in the retort furnace forms semi-coke, which enters the cooling section at the lower part of the retort furnace under its own gravity, and the cooled shale semi-coke is discharged from the bottom. Part of the uncondensed gas gas passes into the burner for combustion, and the other part enters the cooling section of the carbonization furnace to recover the sensible heat of semi-coke, and then enters the...

Embodiment 2

[0032] The raw material powdered oil shale enters the carbonization furnace from the feeding device, and after passing through the drying section, it conducts direct heat exchange with the hot gas gas at 600°C in the constant temperature carbonization section, heats the raw material powdered oil shale to 475°C, and produces Oil and gas: The decomposed oil and gas enter the condensing system from the top of the furnace through the oil and gas collection device to condense, and then cool down to liquid shale oil and enter the oil storage tank. The oil shale that has been fully carbonized in the retort furnace forms semi-coke, which enters the cooling section at the lower part of the retort furnace under its own gravity, and the cooled shale semi-coke is discharged from the bottom. Part of the uncondensed gas gas is passed into the burner for combustion, and the other part enters the cooling section of the retort furnace to recover the sensible heat of semi-coke, and then enters t...

Embodiment 3

[0034] The raw material powdered oil shale enters the retort furnace from the feeding device, and after passing through the drying section, it exchanges heat directly with the hot gas gas at 650°C in the constant temperature retort section, heats the raw material powdered oil shale to 500°C, and produces Oil and gas: The decomposed oil and gas enter the condensing system from the top of the furnace through the oil and gas collection device to condense, and then cool down to liquid shale oil and enter the oil storage tank. The oil shale that has been fully carbonized in the retort furnace forms semi-coke, which enters the cooling section at the lower part of the retort furnace under its own gravity, and the cooled shale semi-coke is discharged from the bottom. Part of the uncondensed gas gas is passed into the burner for combustion, and the other part enters the cooling section of the retort furnace to recover the sensible heat of semi-coke, and then enters the metal honeycomb h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com