Intelligent steamer filling control method for wine making process

A control method and retort installation technology, which are applied in the field of liquor brewing, can solve the problems of energy waste, inability to complete steam rushing, restrict retort installation efficiency, etc., and achieve the effects of saving energy consumption, realizing automation, and improving retort installation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Based on the control system of Jinshiyuan Liquor Industry Luzhou-flavor liquor automatic brewing equipment production line, the infrared thermal imager obtains real-time data through the network port and network cable of the production line system, the steam electromagnetic regulating valve automatically adjusts the opening degree through analog communication, and the retort robot passes through The retort installation software program executes the retort installation action, and then the three are centralized to the industrial computer production line software in the control room through the serial port for real-time communication processing to complete the linkage of the entire retort installation process.

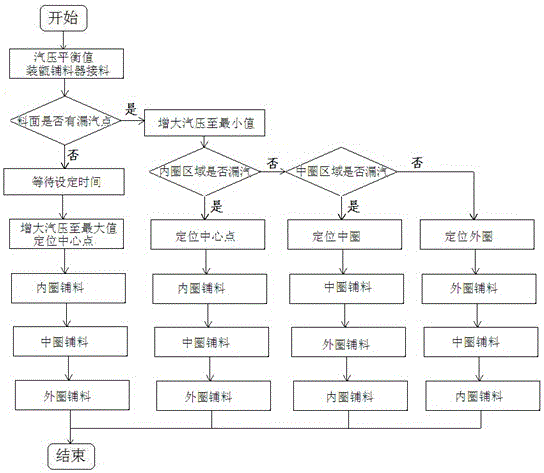

[0017] like figure 1 As shown, the intelligent retort control of the present invention is realized by capturing the steam leakage point on the material surface in the retort barrel by the infrared thermal imager to control the initial position of the retort materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com