Spouting furnace system for semicoke destructive distillation of oil shale or shale semicoke and destructive distillation method thereof

An oil shale and eruption technology, which is applied in coking ovens, special forms of dry distillation, and the petroleum industry, can solve problems such as low efficiency, low oil yield, and low thermal efficiency, so as to reduce residual volume, increase oil yield, The effect of high dry distillation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

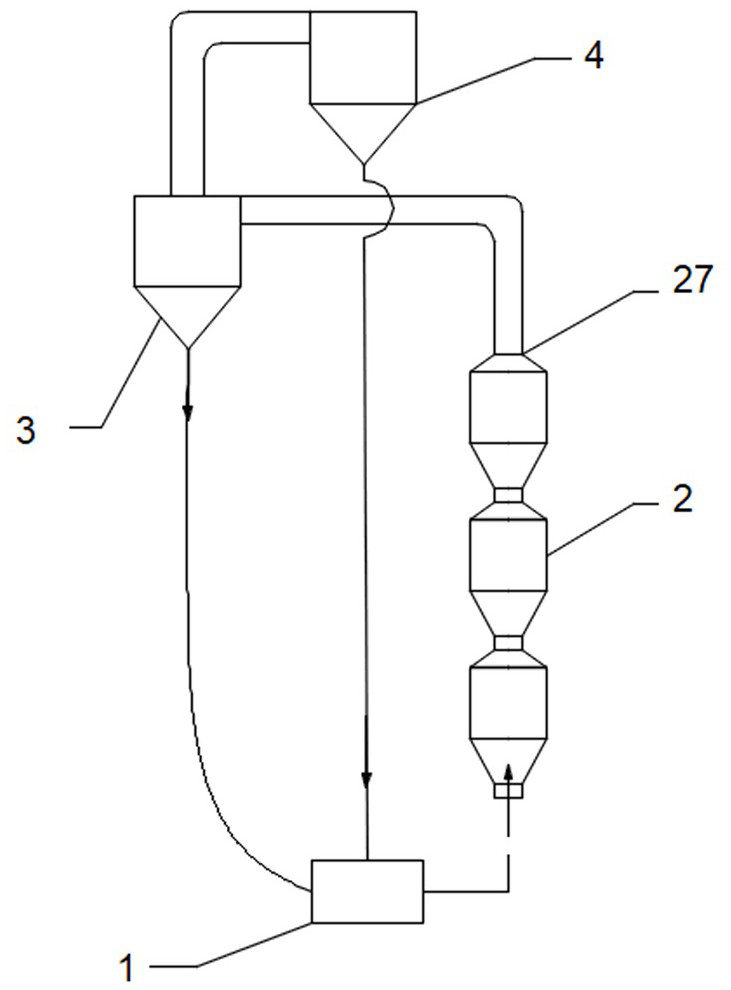

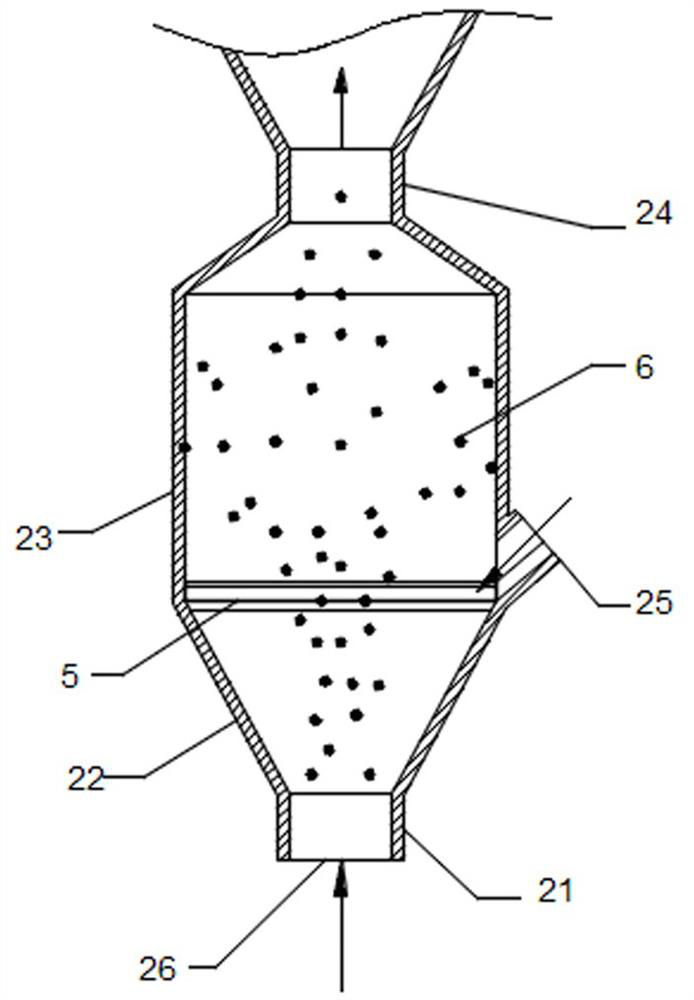

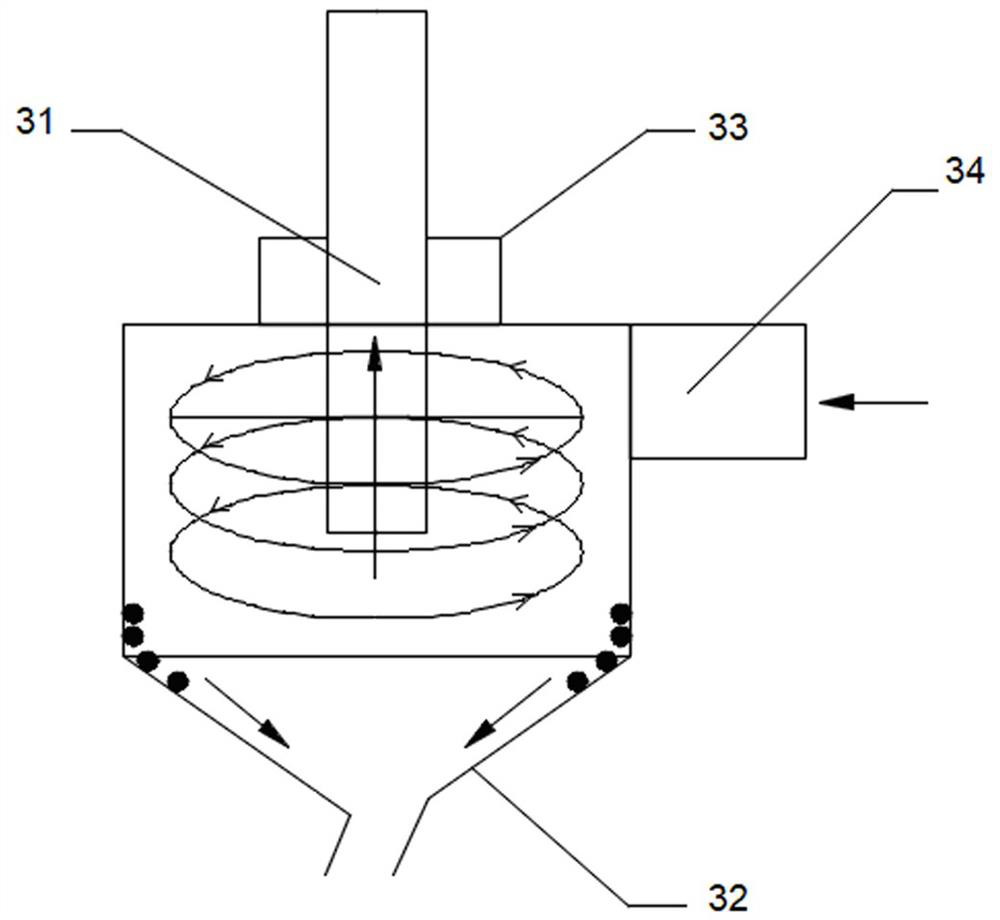

[0046] like Figures 1 to 3 The shown one kind of effervescent furnace system for oil shale or shale semi-coke dry distillation, which includes a effervescent furnace and a cyclone dust collector (3, 4), and the effervescent furnace includes a bottom-to-top pass through a lower neck 21 1. A furnace unit 2 composed of a truncated conical shell 22 and a cylindrical shell 23, wherein the lower neck 21 is connected to the small diameter round port of the truncated conical shell 22, and the cylindrical shell 23 is connected to the large diameter of the truncated conical shell 22 Round ports, the efflux furnace is composed of one to four furnace units 2, and the furnace units 2 are connected by conical shells 24, and the small diameter circles of the conical shells 24 are connected to the lower constriction. At the mouth 21, the large diameter circle of the conical shell 24 is connected to the port of the column shell 23, and the furnace body unit 2 at the bottom of the column shell...

Embodiment 2

[0060] combine Figure 4 to Figure 6 As shown, in the present embodiment, the material spreading box 5 includes a pair of semi-annular material spreading boxes 51 arranged symmetrically and with openings at both ends, and the semi-annular material spreading boxes 51 are all adapted to the shape of the material inlet 25. "匸"-shaped feed inlet 52, and two "匸"-shaped feed inlets 52 are closely connected, and the semi-annular spreading box 51 has a semi-annular chamber, and along the semi-annular chamber to A conical spreading chamber 53 with the same slope as the conical shell 22 is extended downward, and a dividing plate 54 with a feeding hole 55 is arranged between the semi-annular chamber and the conical spreading chamber 53, and The partition 54 is laid with a semi-annular baffle 56 with the same area and opening specifications, and the feed port 52 is provided with a driving rod 57, and the end of the driving rod 57 is connected to the partition nearby by rotation. 54, the ...

Embodiment 3

[0065] The difference from the above-mentioned Example 1 is that in this example, the shale semi-coke after carbonization of oil shale is repeated the above-mentioned dry distillation method: S1: First, the shale semi-coke is crushed and sent to a mill for grinding, Grind until the particles with a particle diameter of less than 1 mm account for more than 90%. The grinding methods include but are not limited to a closed-circuit grinding system matched with a tube mill and a powder separator, and a roller grinding system with a powder separator. The wind used in the process is hot air at 180-250°C to dehydrate the materials in the grinding process;

[0066] S2: The kiln exhaust gas is introduced into the furnace body from the lower neck 21 of the furnace body unit 2 at the bottom of the effervescent furnace, and the material obtained from the above S1 is sprinkled into the furnace body from the feeding port, and the oil and gas above the effervescent furnace is turned on Outlet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com