Lightweight oil shale hierarchical destructive distillation equipment

A light-weight oil shale technology, which is applied in the field of lightweight oil shale graded retort equipment, can solve the problems of unutilized latent heat, large power consumption, and low thermal efficiency, so as to reduce the configuration of grinding equipment, ensure stability, and improve The effect of oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

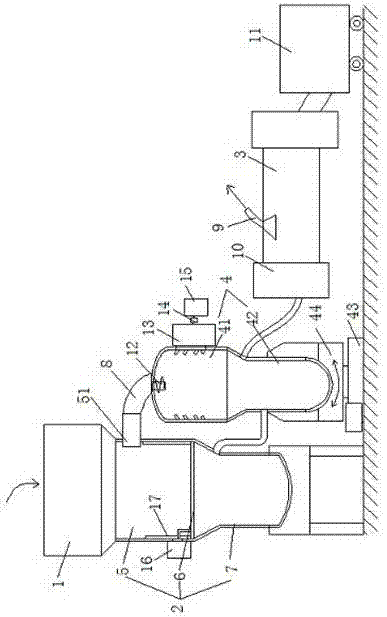

[0018] Such as figure 1 As shown, a lightweight oil shale graded retort equipment includes a crushing device 1, a compression and classification device 2, a sandblasting retort device 4, a filter 10, an oil-gas separation device 3, an oil-gas dust collector 9, and an oil collector connected in sequence 11, wherein: the compression and classification device 2 is a cylindrical structure, and it includes a compression and classification chamber 5 connected sequentially from top to bottom, a mesh screen 6 that can move up and down, and a first-stage dry distillation calciner 7, wherein the diameter of the compression and classification chamber 5 is Larger than the diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com