Permanent double layer well body structure for realizing gas well continuous circulation

A wellbore structure and permanent technology, applied in wellbore/well components, flushing wellbore, earthwork drilling, etc., can solve the problems of unrealized continuous circulation and narrowness of drilling operations, and achieve the effect of continuous reservoir evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

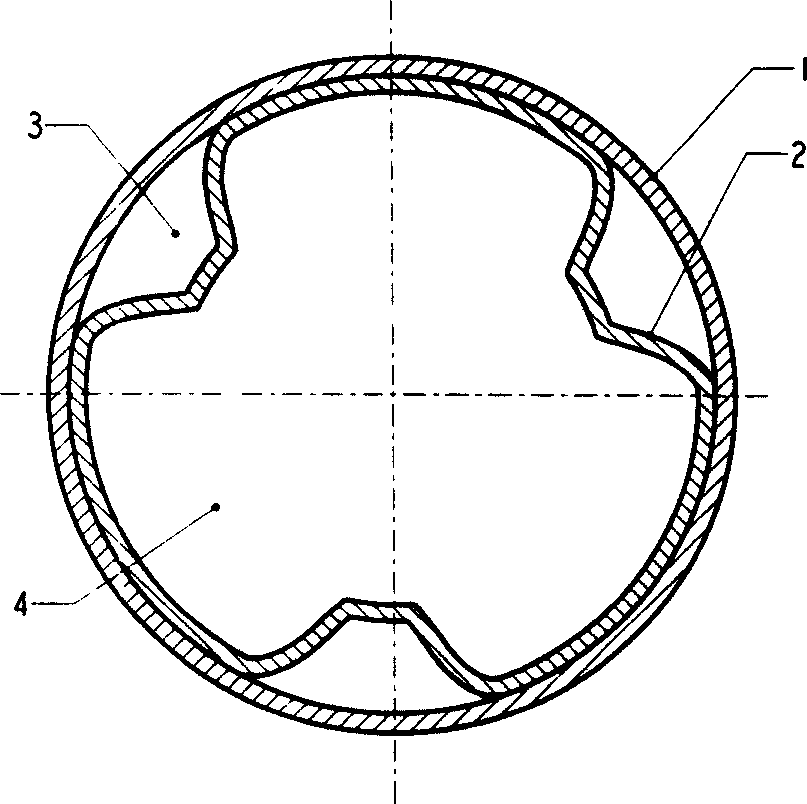

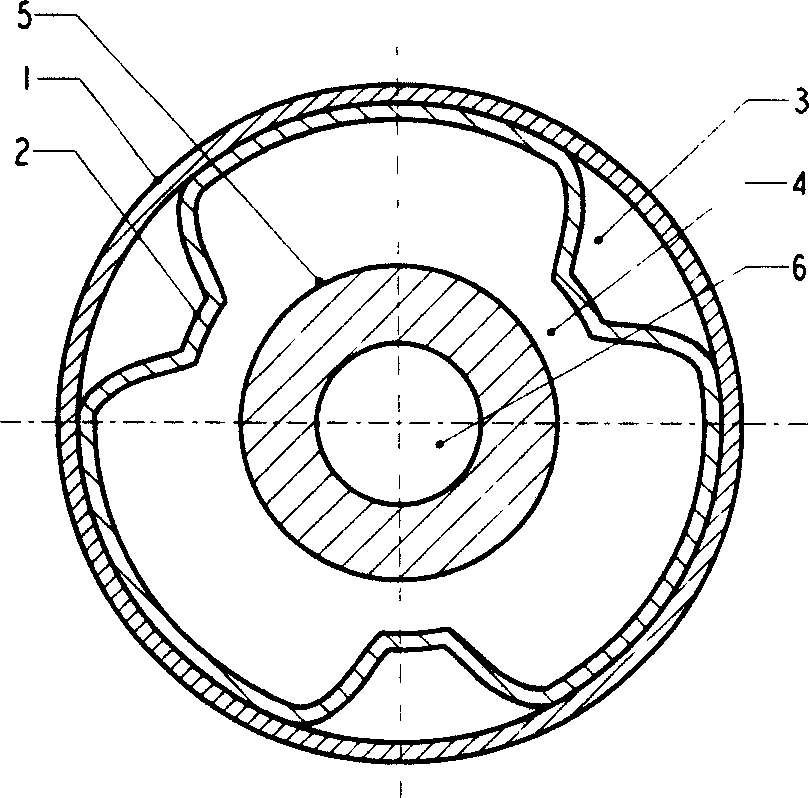

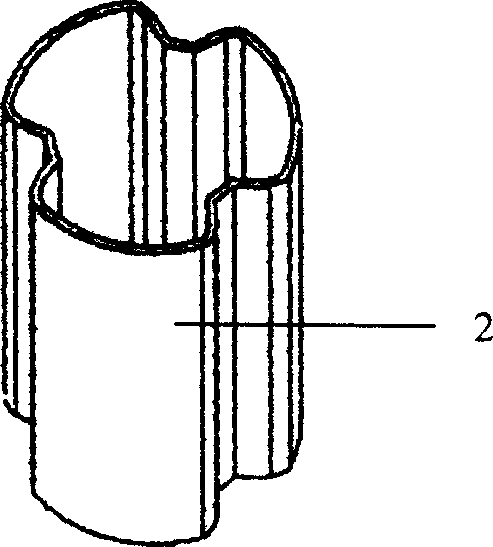

[0031] The double-layer wellbore structure includes a cemented casing (or a solid open hole wall) (1), a thin-walled inner pipe (2) inside the casing (1), and a thin-walled inner pipe (2) It can be a special-shaped tube or a round thin-walled tube. The upper end of the inner pipe (2) is fixed on the wellhead with a casing head adapted to it, and there is an upper guide nipple for guiding the drill bit and the centralizer to enter the inner pipe (2) when running in; the lower end of the inner pipe (2) is connected to the casing (1) It adopts plug-in sliding spline structure connection (allows the inner pipe (2) to slide up and down in a small range, but cannot rotate in the circumferential direction, so as to prevent the inner pipe (2) from twisting and deforming in the well), and guides the drill bit when pulling out, The centralizer enters the lower guide nipple of the inner tube (2). The special-shaped inner pipe (2) can be trilobal or other shapes. The entire inner pipe (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com