Continuous circulation device and method for operation of assembling casing pipe

A circulation device and casing technology, applied in drilling equipment and methods, earthwork drilling, drilling equipment, etc., can solve problems such as difficult control of liquid pressure, long static time, resistance in casing running, etc., to reduce shrinkage diameter and collapse, reasonable and compact structure, and the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

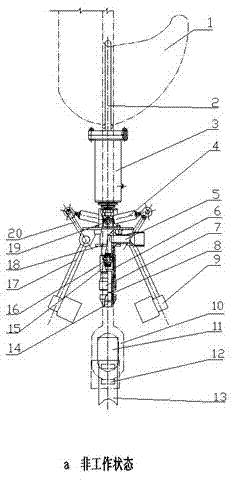

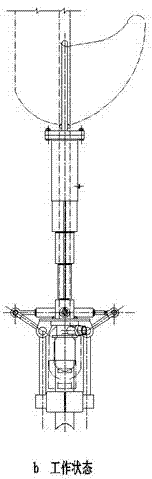

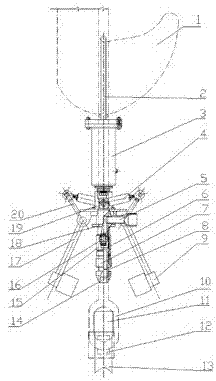

[0031] The present invention will be described in detail below with reference to the drawings.

[0032] The continuous circulation device for casing running operation of the present invention includes a clamping system and a perfusion and circulation system.

[0033] The clamping system includes: a hanging ring 2, a vertical hydraulic cylinder 3, a combined connecting frame 19, a combined connecting head 18, an earring connecting liquid cylinder 4, a driving arm 20, a secondary grasping arm 17 and a secondary grasping card 9. The vertical hydraulic cylinder 3 is connected below the hanging ring 2, and the combined connecting frame 19 and the combined connecting head 18 are connected below the vertical hydraulic cylinder 3. The rodless ends of the two earrings connecting the hydraulic cylinder 4 are hingedly mounted on the combined connecting frame 19 back to back, There is a rod end connected to the driving arm 20, the other end of the driving arm 20 is fixedly connected to the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com