Technological method for producing biogas by utilization of organic matter

A technology of bio-natural gas and process method, which is applied in the field of bio-energy development and environmental protection, and can solve the problems of high production cost of bio-natural gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

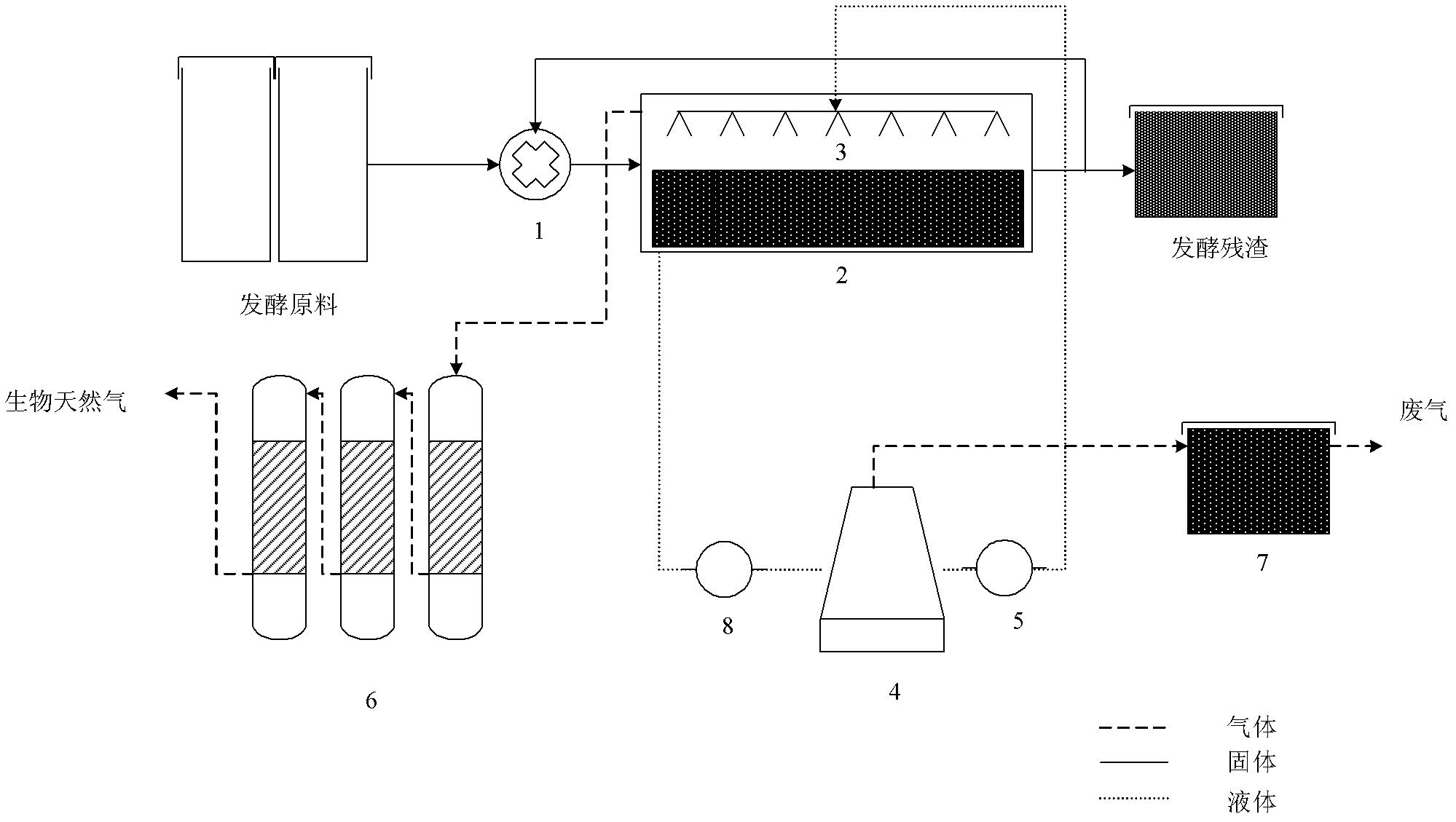

[0025] The present invention provides a process method for producing bio-natural gas by utilizing organic matter. The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods. The following detailed description is only to illustrate the general principles of the present invention, and is not restrictive. Reasonable adjustments and modifications can be made according to the different properties and processing requirements of the raw materials to be processed in the actual application process.

[0026] refer to figure 1 , first, according to the physical and chemical characteristics of organic waste and fermentation requirements, the raw materials are sent to the pretreatment device 1, and according to the properties of the raw materials, physical, biological or chemical methods can be used for pretreatment, and then the inoculum and fermentation raw materials are added to carry out Mixing, the mass ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com