Wire feeding reduction gearbox

A reduction box and wire feeding technology, which is applied in the field of spring equipment manufacturing and processing, can solve the problems of decreased positioning accuracy of the wire feeding wheel, troublesome adjustment of the wire feeding wheel, and inconvenient adjustment operation, so as to improve production efficiency, reduce work burden, Avoid intermittently added effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

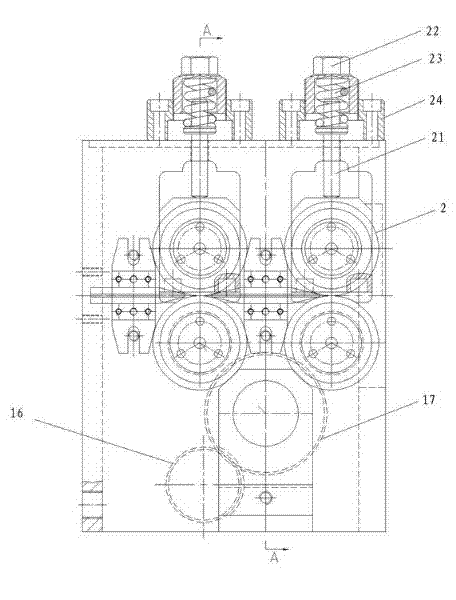

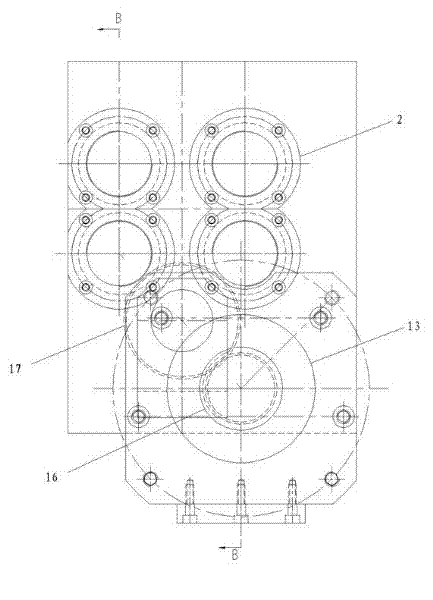

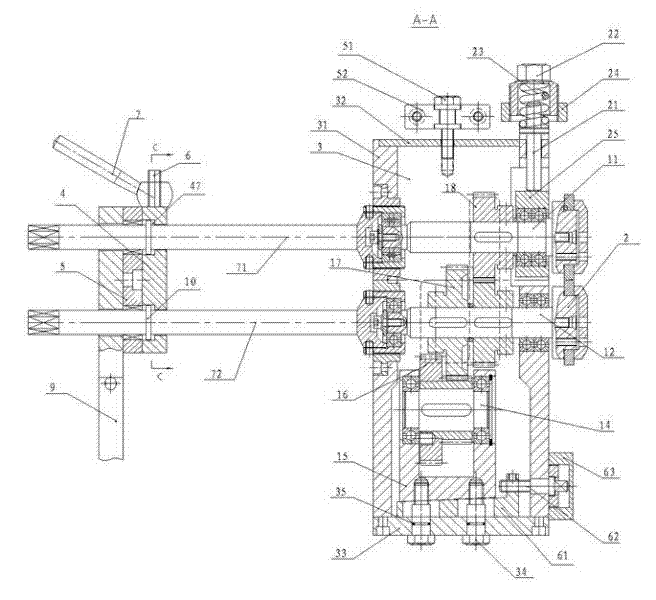

[0026] combine Figure 1 to Figure 5 , the preferred embodiments of the present invention will be described in further detail.

[0027] A wire-feeding reduction box, including a wire-feeding shaft 1 and a wire-feeding wheel 2. In this embodiment, there are four wire-feeding shafts 1, which are divided into two groups and arranged up and down. The upper one is the upper feeding shaft 11, and the lower one is the lower feeding shaft 12 , the upper wire feeding shaft 11 and the lower wire feeding shaft 12 are all worn and supported on the wire feeding box body 3, and the end position stretches out of the wire feeding box body 3, and the wire feeding wheel 2 is installed.

[0028] The tails of the upper wire feed shaft 11 and the lower wire feed shaft 12 are respectively connected to the upper wire feed adjustment shaft 71 and the lower wire feed adjustment shaft 72, and a fixing mechanism is installed on the upper wire feed adjustment shaft 71 and the lower wire feed adjustment s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com