Clamping-installing type quick clamping mechanism and installation method thereof

A clamping mechanism and clamping technology, which is applied in the direction of workpiece clamping devices and manufacturing tools, can solve the problems of insufficient flexibility of the clamping device and narrow application range, and achieve the effect of flexible pressure adjustment and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

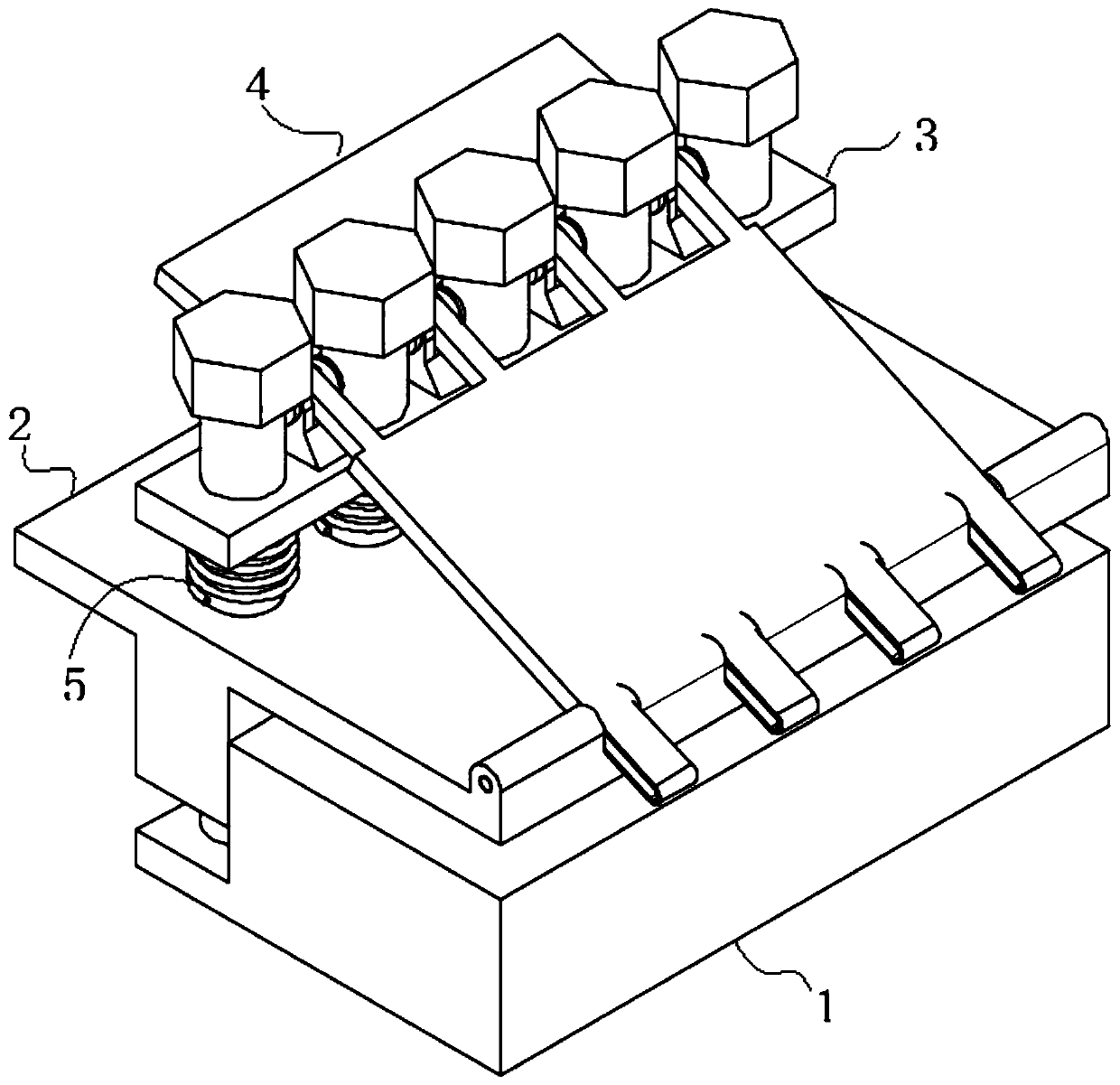

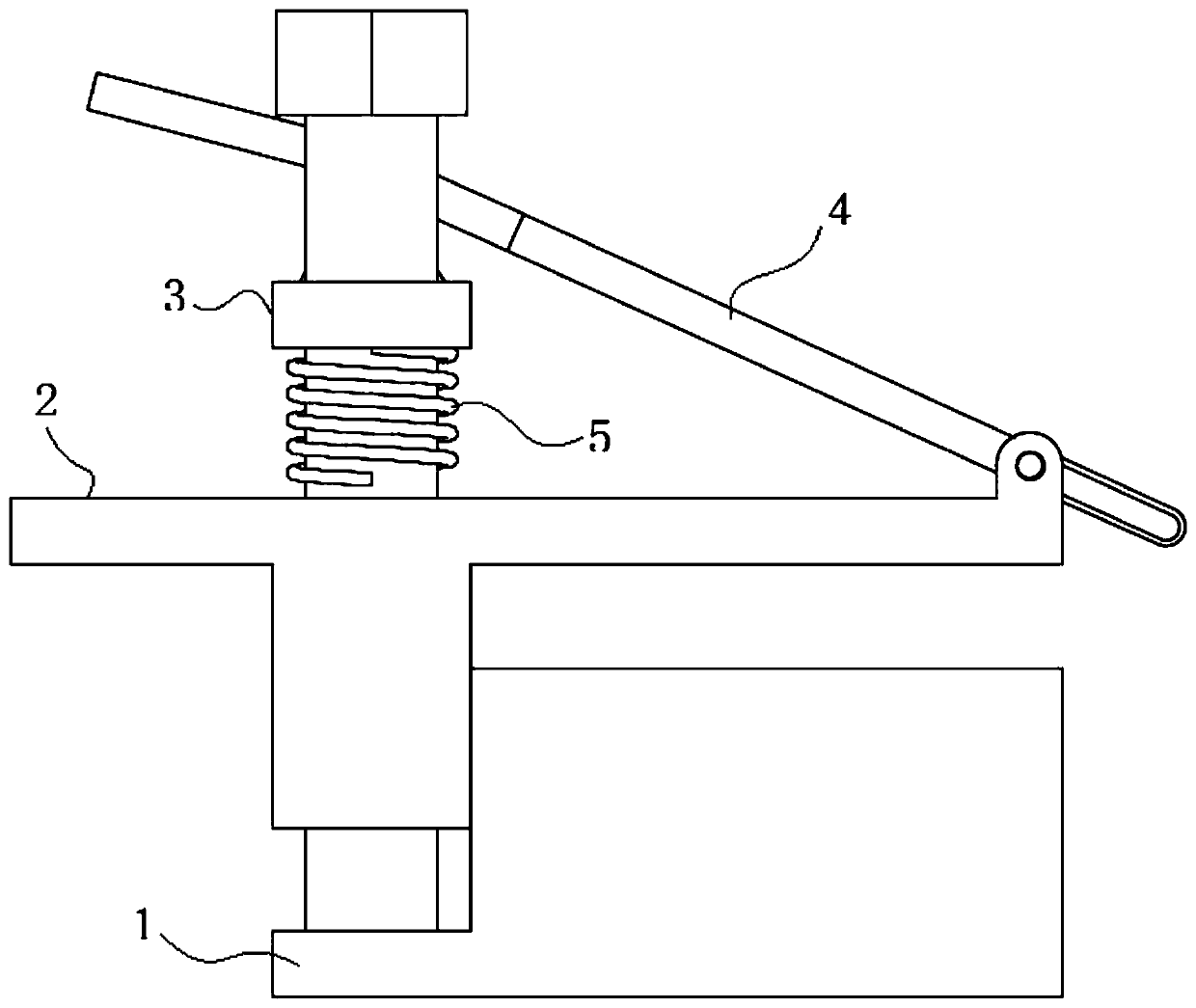

[0041] see figure 1 and 2 As shown, the present invention is a clamping type quick clamping mechanism, including a first clamping plate 1 and a second clamping plate 2, and a pressing plate 3 is arranged on the second clamping plate 2;

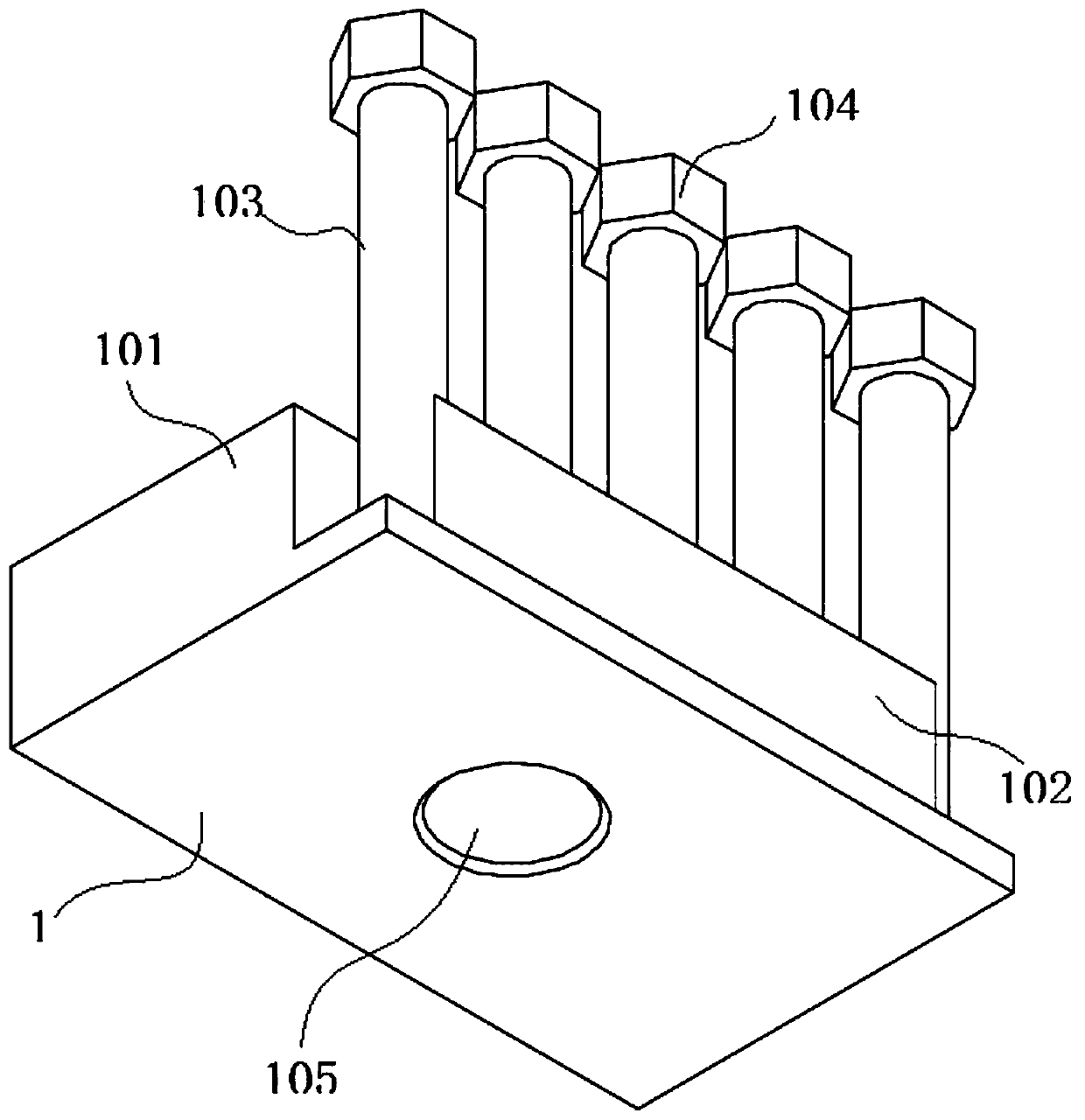

[0042] Such as image 3 As shown, one surface of the first splint 1 is provided with clamping blocks 101 and guide blocks 102, and the opposite surface of the first splint 1 is provided with connecting holes 105; the surface of the guide block 102 is uniformly provided with several guide posts 103; One end is provided with a limit adjustment block 104; the connecting hole 105 is connected with a rod, and the rod adopts a telescopic rod or a threaded rod to support the first splint 1; the limit adjustment block 104 can generally be realized by using a nut, or by setting a double The nut is used to adjust the clamping pressure between the first splint 1 and the second splint 2 by adjusting the position of the nut on the guide column 103 .

[...

Embodiment 2

[0056] see figure 1 and 2 As shown, the present invention is a clamping type quick clamping mechanism, including a first clamping plate 1 and a second clamping plate 2, and a pressing plate 3 is arranged on the second clamping plate 2;

[0057] Such as image 3 As shown, one surface of the first splint 1 is provided with clamping blocks 101 and guide blocks 102, and the opposite surface of the first splint 1 is provided with connecting holes 105; the surface of the guide block 102 is uniformly provided with several guide posts 103; One end is provided with a limit adjustment block 104; the connecting hole 105 is connected with a rod, and the rod adopts a telescopic rod or a threaded rod to support the first splint 1; the limit adjustment block 104 can generally be realized by using a nut, or by setting a double The nut is used to adjust the clamping pressure between the first splint 1 and the second splint 2 by adjusting the position of the nut on the guide column 103 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com