Portable metallographic phase automatic sample grinding device

A portable and sample grinding technology, which is applied in the direction of measuring devices, sampling, and test sample preparation, etc., can solve the problems of low sample grinding efficiency, poor sample grinding effect, and time delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

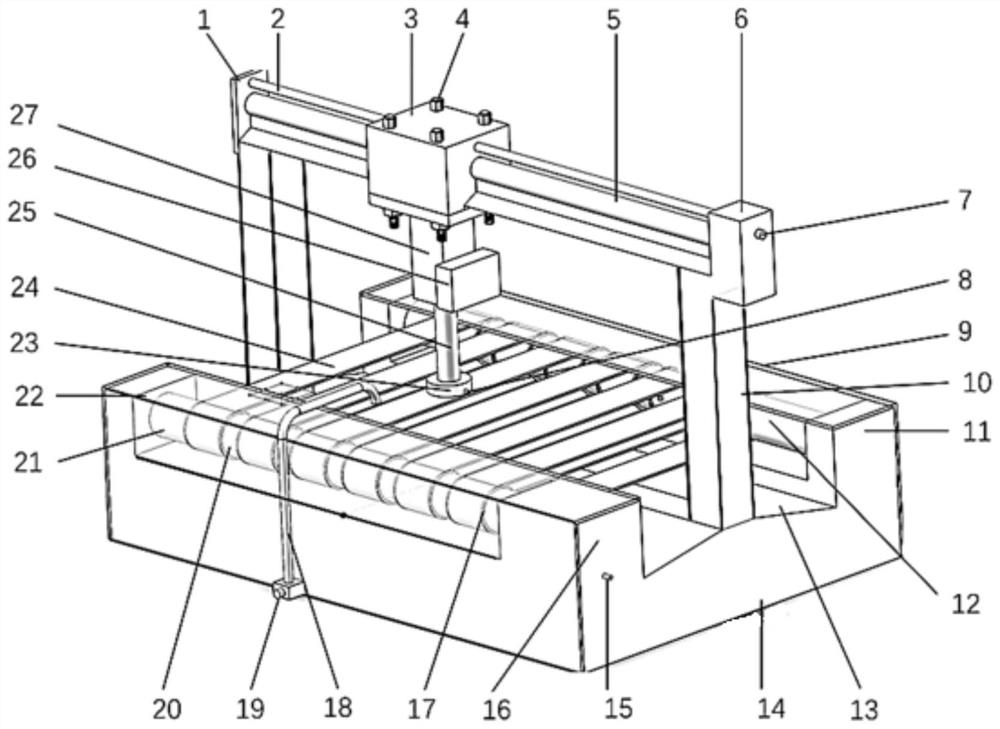

[0031] Embodiment 1 A portable metallographic automatic sample grinding device according to the present invention includes:

[0032] A base body 14, the top of the base body is provided with a sunken processing surface 13, and a power transmission unit is installed between two opposite mounting edges of the base body 14;

[0033] The support unit includes a guide rail frame 5 and a support frame 10, the guide rail frame 5 and the guide rail frame 5 are mounted directly above the power transmission unit through the support frames 10 at both ends, and the guide rail frame 5 is installed in the axial direction a guide rail, and the guide rail spans the processing surface 13;

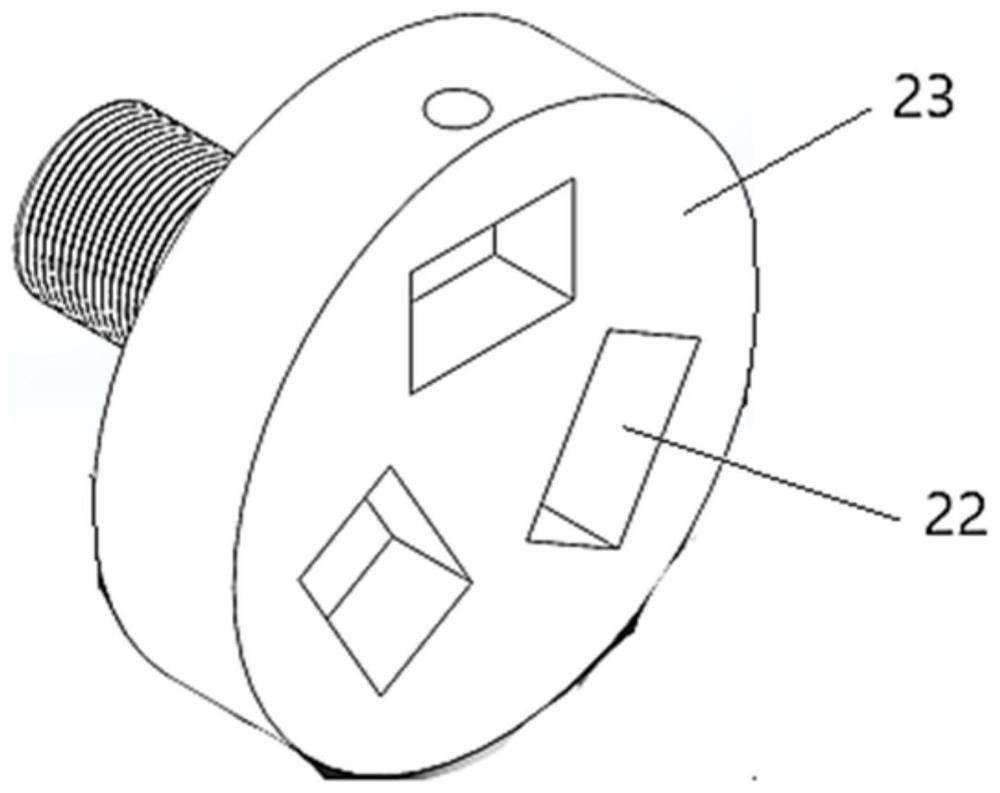

[0034]A grinding sample unit, including a drive shaft drive motor protection box 16, a drive shaft drive motor, a main drive shaft 21, a slave drive shaft 12 and several groups of grinding sample conveyor belt assemblies arranged side by side between the master and slave drive shafts, the base 14 The drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com