Double-cylinder nailing method

A double-cylinder, main-cylinder technology, applied in the field of nailing, can solve the problems of inability to realize automatic gas compensation, increase in equipment weight and volume, and difficulty in achieving effective compression, and achieve simple and effective control methods, improve nailing power, simplify structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

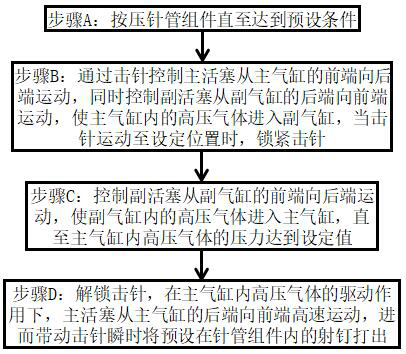

[0079] The invention discloses a double-cylinder nailing method, such as figure 1 shown, it includes the following steps:

[0080] Step A: Startup Preparation

[0081] The needle tube assembly is pressed until a preset condition is reached, and the preset condition is mainly the pressing pressure or the movement displacement of the needle tube in the needle tube assembly, and its specific value can be set according to actual needs.

[0082] Step B: Firing pin in place

[0083] First control the firing pin to move to the rear end of the main cylinder, and then drive the main piston to move from the front end of the main cylinder to the rear end through the firing pin, while the auxiliary piston moves from the rear end of the auxiliary cylinder to the front end, so that the high-pressure gas in the main cylinder enters the auxiliary cylinder. Air cylinder, when the firing pin moves to the set limit position, the firing pin enters the limit state.

[0084] Step C: Pressurized ...

Embodiment 2

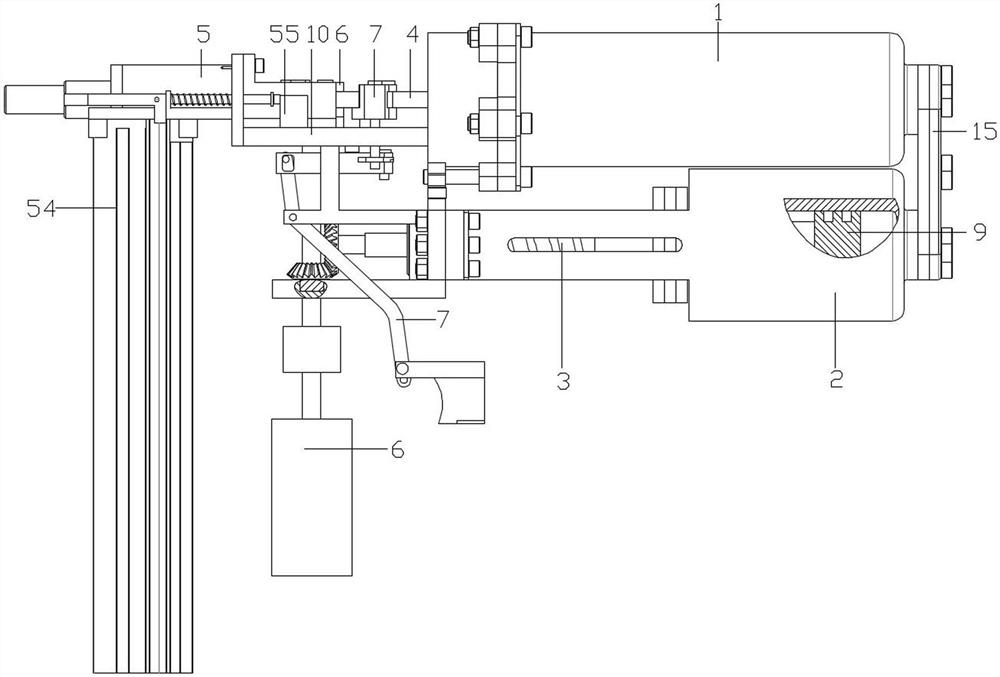

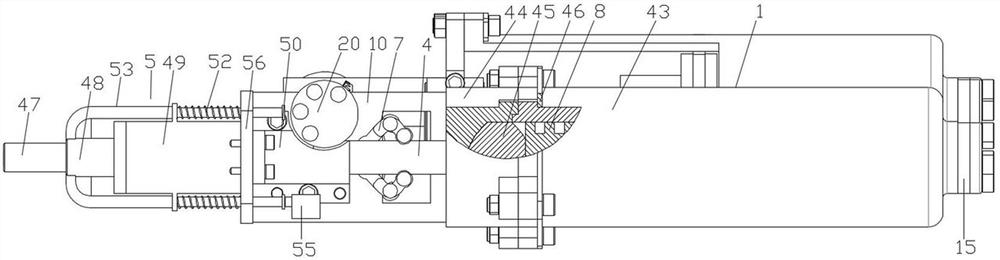

[0090] The invention discloses a double-cylinder nailing method, such as Figure 1-4 As shown, the method includes a main cylinder 1 , a secondary cylinder 2 , a linear motion mechanism 3 , a sensor 55 , a firing needle 4 , a needle tube assembly 5 , a driving mechanism 6 and a limit release mechanism 7 . in,

[0091] The master cylinder 1 includes a cylinder block 43, a cylinder head 44, a shock absorbing pad 45 and a washer 46. The cylinder head 44 is sealed and fixed on the cylinder block 43 by bolts. The washer 46 is provided with bolt holes around it, and the washer 46 passes through the bolts and the bolt holes. It is fixed between the cylinder head 44 and the cylinder block 43, and the shock absorbing pad 45 is fixed in the cylinder head 44 to reduce the vibration during the use of the injection gun. The cylinder head 44 has a certain internal space. In order to improve the damping effect, it is preferable that the size and shape of the damping pad seat 45 are adapted ...

Embodiment 3

[0112] On the basis of Embodiment 2, this embodiment further defines the structures of the drive mechanism 6, the limit release mechanism 7 and the linear motion mechanism 3, as follows:

[0113] like Figure 2-4 As shown, the drive mechanism 6 includes a motor 16, a first reducer 17, a second reducer 18, a one-way clutch (not shown in the figure), a transmission shaft 19, a toggle assembly 20 and a bevel gear 21, wherein, The motor 16 , the first reducer 17 , the second reducer 18 , the one-way clutch, the transmission shaft 19 and the toggle assembly 20 are connected in sequence, and preferably the one-way clutch is wrapped in the second reducer 18 . Of course, as required, a third speed reducer may also be provided at the rear end of the one-way clutch. The toggle assembly 20 is arranged on one side of the firing pin 4 for controlling the action of the firing pin 4 through the toggle teeth 11, and the bevel gear 21 is arranged between the first reducer 17 and the second re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com