Supercritical carbon dioxide secondary reheat coal-fired power generation boiler system

A secondary reheat, carbon dioxide technology, applied in indirect carbon dioxide emission reduction, steam boilers, steam superheating and other directions, can solve the problem of substandard superheat, and achieve the effect of superheat reaching the standard, high heat transfer efficiency, and novel structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

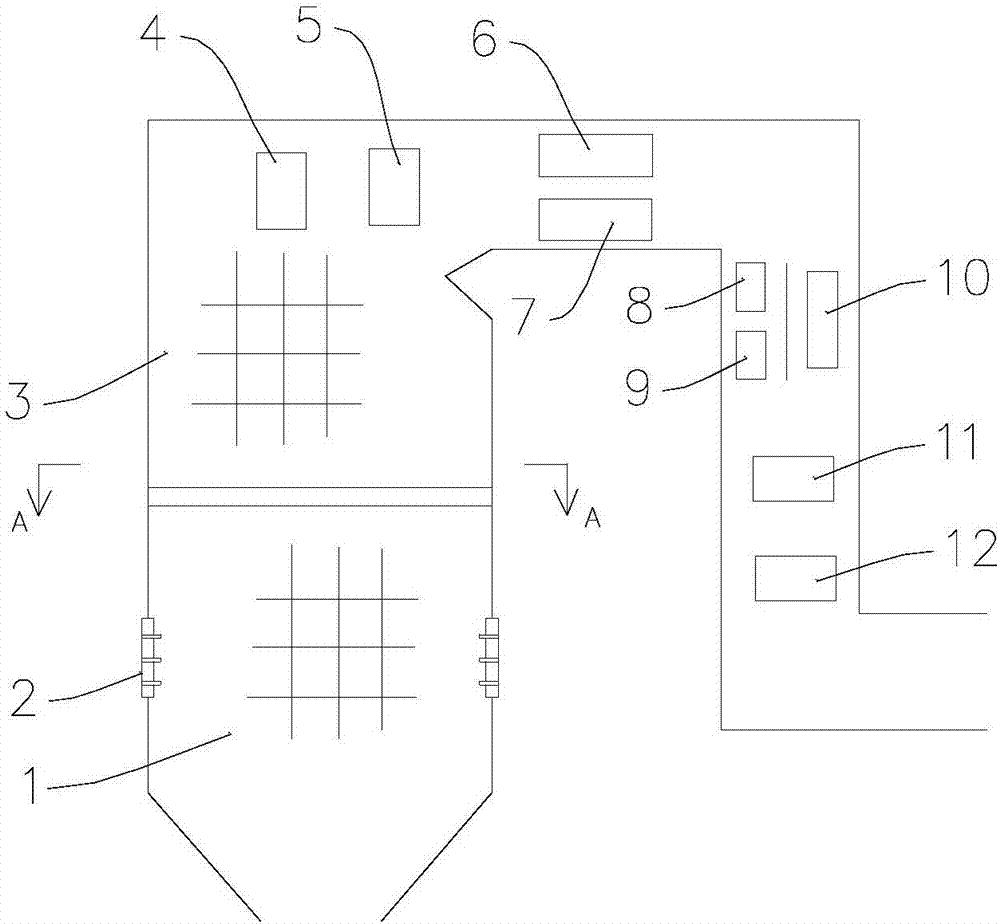

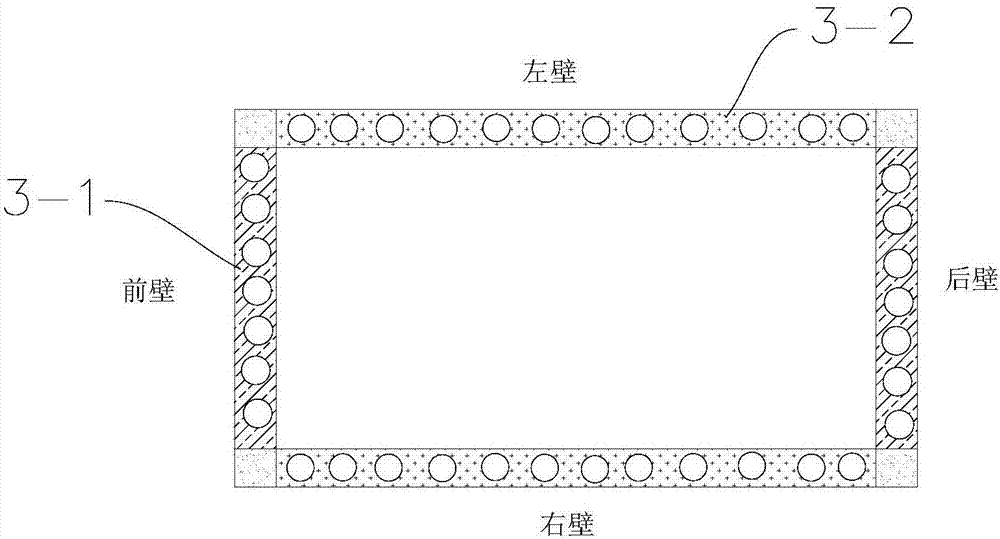

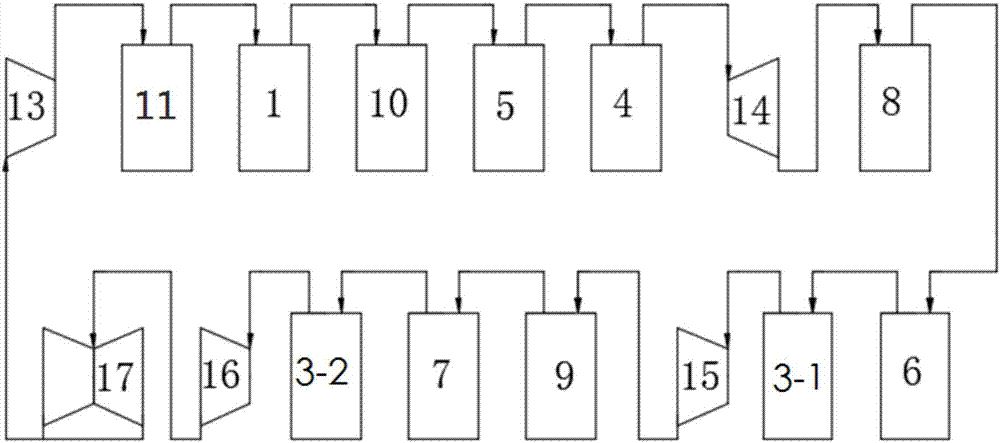

[0033] like figure 2 As shown, under specific load requirements, the front wall, rear wall and corresponding independent headers are primary reheating walls 3-1, and the left and right walls and corresponding independent headers are secondary reheating walls 3-2 .

[0034] The opening and closing of the valve and the specific connection relationship are as follows: the valve on the connecting pipeline between the outlet of the primary high-temperature reheater 6 and the independent headers at the respective lower ends of the front wall and the rear wall is opened, and the outlet of the secondary high-temperature reheater 7 is connected to the The valves on the connecting pipes between the respective lower end independent headers of the left wall and the right wall are opened, and the valves on the connecting pipes between the respective upper end independent headers of the front wall and the rear wall and the inlet of the high-pressure cylinder 15 of the gas turbine are opene...

Embodiment 2

[0036] Under another specific load requirement, the front wall, left wall and corresponding independent headers are primary reheating walls 3-1, and the rear wall, right wall and corresponding independent headers are secondary reheating walls 3-2.

[0037] The opening and closing of the valve and the specific communication relationship are as follows: the valve on the connecting pipeline between the outlet of the primary high-temperature reheater 6 and the independent headers at the respective lower ends of the front wall and the left wall is opened, and the outlet of the secondary high-temperature reheater 7 is connected to the The valves on the connecting pipes between the respective lower end independent headers of the rear wall and the right wall are opened, and the valves on the connecting pipes between the respective upper end independent headers of the front wall and the left wall and the inlet of the high-pressure cylinder 15 of the gas turbine are opened. Open, the val...

Embodiment 3

[0039] Under another specific load requirement, the front wall, rear wall, left wall and corresponding independent headers are primary reheating walls 3-1, and the right wall and corresponding independent headers are secondary reheating walls 3-2.

[0040] The opening and closing of the valves and the specific connection relationship are as follows: the valves on the connecting pipes between the 6 outlets of the primary high-temperature reheater and the independent headers at the lower ends of the front wall, the rear wall and the left wall are opened, and the valves on the connecting pipes of the secondary high-temperature reheater 7. The valve on the connecting pipe between the outlet and the independent header at the lower end of the right wall is opened, and the valve on the connecting pipe between the independent upper end of the front wall, the rear wall and the left wall and the inlet of the high-pressure cylinder 15 of the gas turbine is opened. The valve of the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com