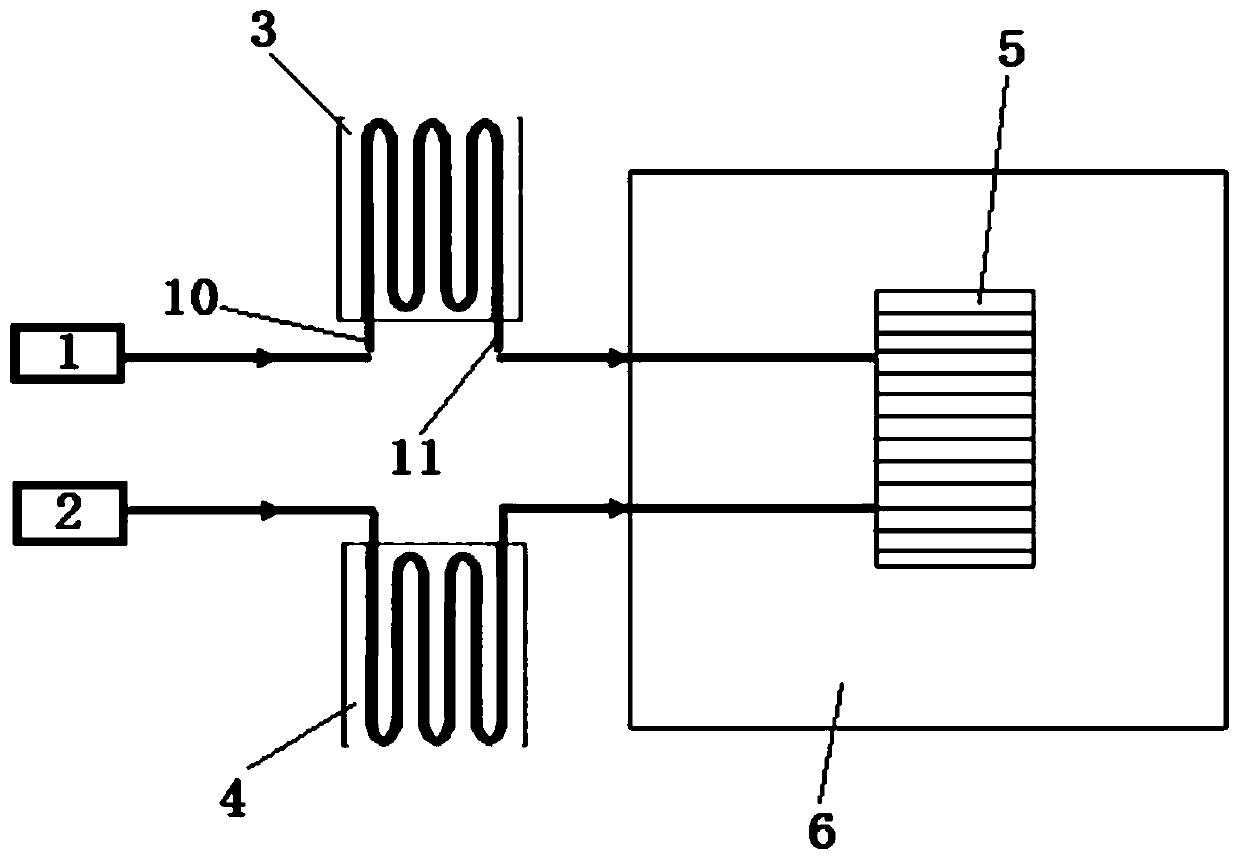

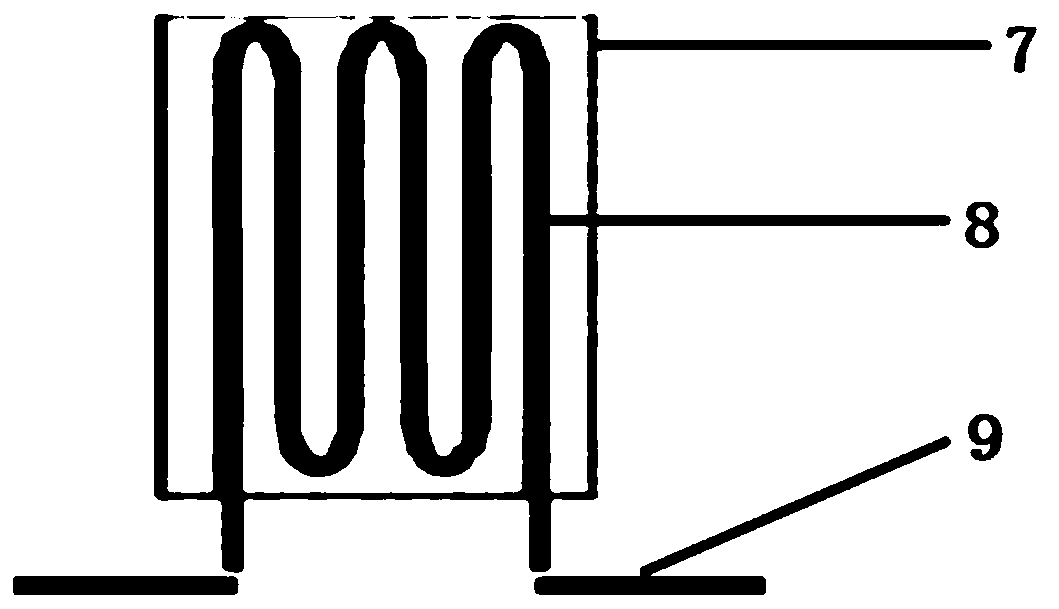

System and method for gas precooling and cooling in low-temperature starting test of fuel cell

A technology of fuel cells and fuel cell stacks, which is applied to fuel cells, electrical components, circuits, etc., can solve the problem of increasing the refrigeration load of high and low temperature environmental boxes, the gas temperature cannot be reduced to the required temperature, affecting the stack or system shutdown. Purging and other problems to achieve the effect of satisfying large-span range flow, fast and effective cooling effect, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The fuel cell stack with a power of 2kW is tested at a low temperature of -20°C. The hydrogen / air flow rate required in the test is 20nlpm / 80nlpm, and the gas temperature must reach -20°C before entering the stack. The temperature of the hydrogen precooling system 3 and the air precooling system 4 of the present invention is used to lower the temperature, and the actual temperature of the gas entering the stack is -20°C.

Embodiment 2

[0045] A fuel cell stack with a power of 20kW is tested at a low temperature of -20°C. The hydrogen / air flow required for the test is 300nlpm / 1200nlpm, and the gas temperature must reach -30°C before entering the stack. The temperature of the hydrogen precooling system 3 and the air precooling system 4 of the present invention is used to lower the temperature, and the actual temperature of the gas entering the stack is -30°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com