Industrial pulverized coal boiler exhaust gas recycling low-nitrogen combustion method and system

A flue gas recirculation and pulverized coal boiler technology, applied in the direction of combustion method, flue gas combustion, combustion type, etc., can solve the problems of unstable flame and low burnout rate, achieve simple structure, reduce pollution, reduce power and The effect of operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

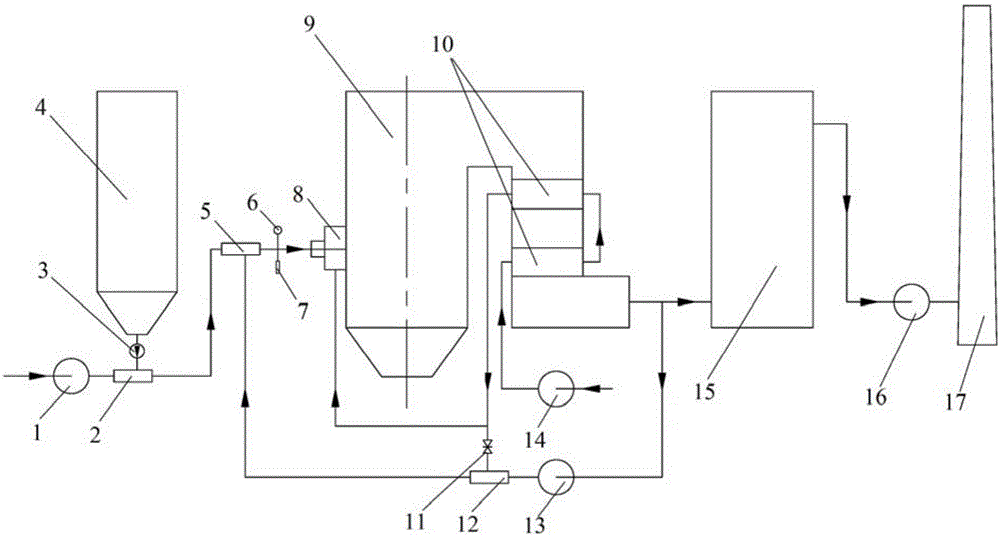

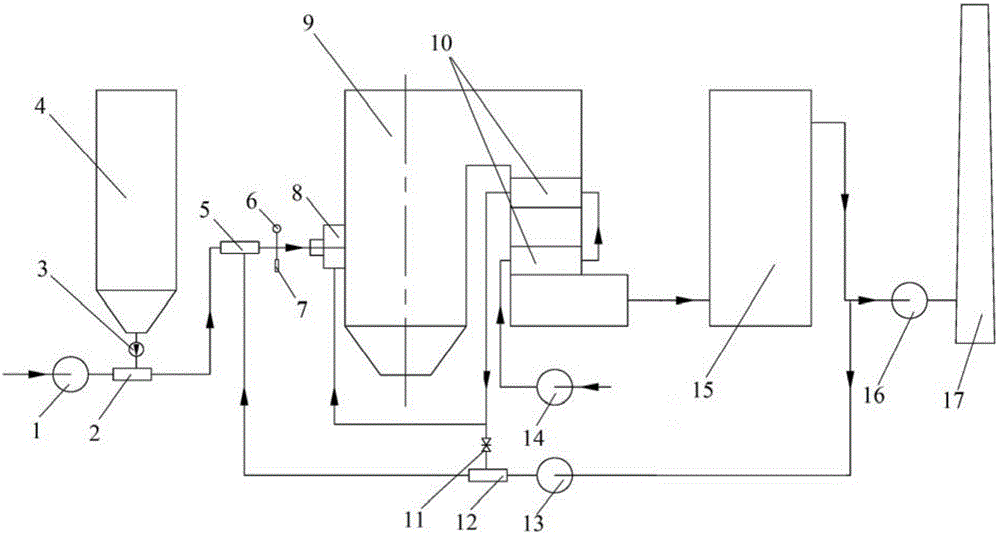

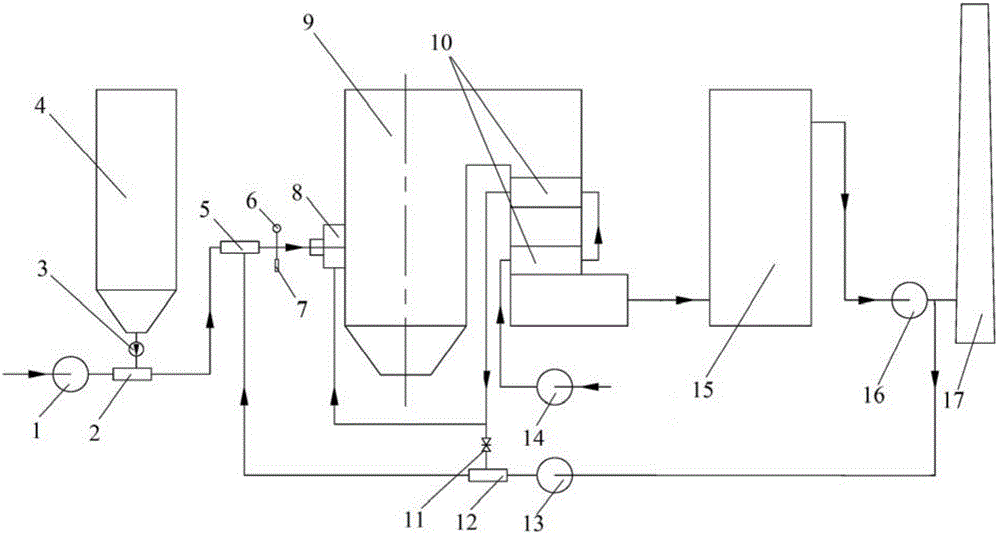

[0021] Such as figure 1 As shown, the flue gas recirculation low-nitrogen combustion system of an industrial pulverized coal boiler includes: a primary fan 1, a pulverized coal bin 4, a powder feeder 3, a third mixer 2, a first mixer 5, an oxygen meter 6, and a thermometer 7 , boiler, secondary fan 14, recirculation fan 13, second mixer 12, dust collector 15, induced draft fan 16 and chimney 17. The boiler includes a swirl burner 8 , a furnace 9 and an air preheater 10 . The arrows in the figure indicate the airflow direction.

[0022] The pulverized coal bin 4, the powder feeder 3, and the third mixer 2 are connected in sequence. The primary blower 1 is connected with the first mixer 5 through the third mixer 2 . The first mixer 5 is connected to the swirl burner 8 and the second mixer 12 respectively. The oxygen meter 6 and the thermometer 7 are arranged between the connecting pipeline of the first mixer 5 and the swirl burner 8, and are respectively used for measuring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com