Method for producing soft pack batteries based on measurable battery internal temperature device

A technology of internal temperature and pouch battery, which is applied in the direction of measuring devices, electrolyte storage battery manufacturing, and electrical devices, and can solve problems such as errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] The invention provides a pouch battery manufacturing method based on a device that can accurately measure the internal temperature of the battery. After the short-circuit test of the test device is completed, it needs to be baked and dried. The drying parameters are: baking temperature 80°C, vacuum baking time 12h, Nitrogen was changed every 2 hours. For core package 6, laminated core package 6 is selected as the carrier. Here, a lithium iron phosphate type (wet-mixed ingredient) soft-pack laminated battery using internal model 50200125-EV10Ah technology is selected. The used core package should be dried at room temperature and humidity. ≤20% of the environment for assembly.

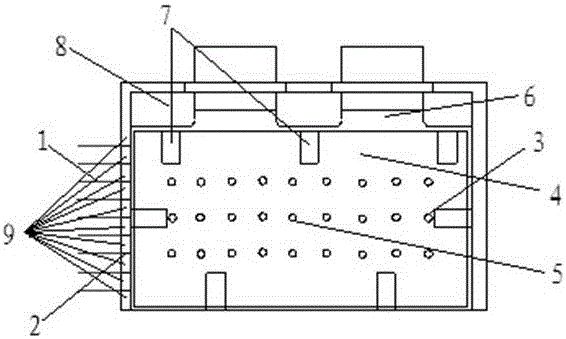

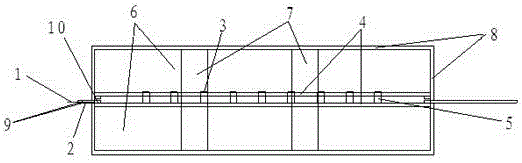

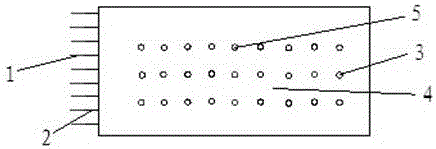

[0047] Such as image 3 As shown, the thermistor 5 is embedded in the thermistor embedding hole 3 of the corresponding circuit board 4 , and the paths of each thermistor 5 are tested to ensure the smoothness of the circuit board 4 . The size of the circuit board 4 and the number of thermistor in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com