Stereoscopic maintenance tunnel for precast concrete members

A technology of prefabricated concrete and tunnels, which is applied in the direction of manufacturing tools and ceramic molding machines, etc., which can solve the problems of large area occupied by cover film heating, large equipment investment, and large energy consumption, and achieve lower curing temperature, large volume, and many components. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

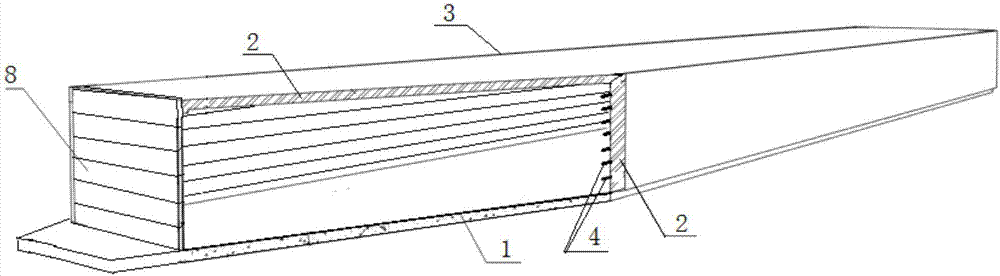

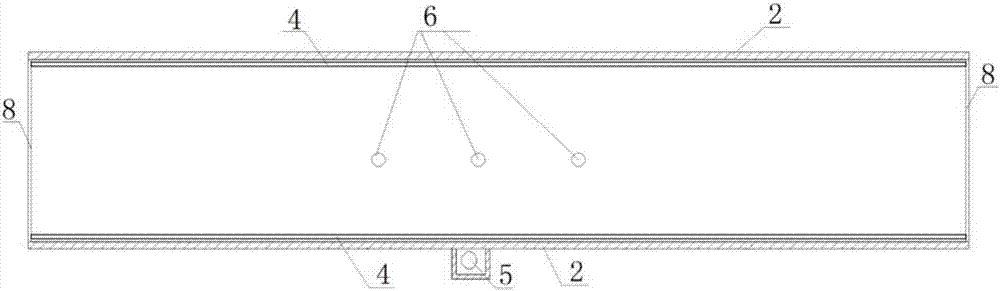

[0037] Such as Figure 1-2As shown, a three-dimensional maintenance tunnel for prefabricated concrete components includes a long tunnel 3 surrounded by a base 1 and an outer shell 2. The outer shells 2 around the tunnel 3 are all made of thermal insulation materials or contain thermal insulation materials. structure, on both sides of the tunnel 3, there are multi-layer tracks 4 running through the tunnel 3. The track 4 is a continuous track, just like the crane beam of the factory building, hanging on the walls on both sides of the tunnel 3. For steam heating equipment, both ports of the tunnel 3 are provided with openable and closable isolation doors 8 for the mold table 7 carrying the prefabricated parts to pass through, and the inside of the tunnel 3 is a closed steam curing room 10 containing multi-layer tracks. According to the production requirements, the number of layers of the track 4 and the length of the track 4 are designed to facilitate the sliding of the concrete ...

Embodiment 2

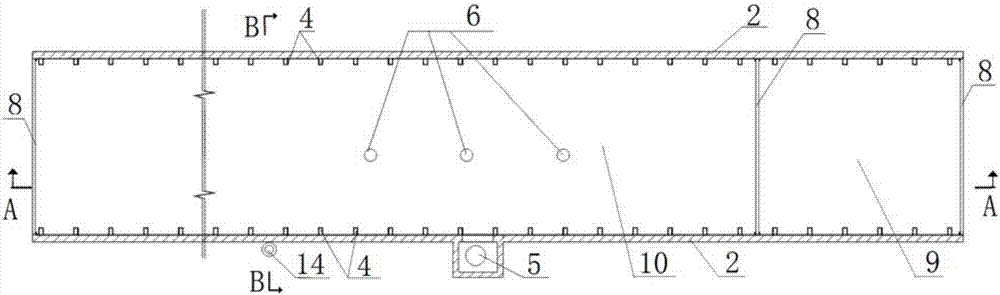

[0041] refer to Figure 3-5 As shown, it is another specific embodiment of the present invention, which is basically the same as Embodiment 1, except that a preheating chamber 9 that can automatically communicate with the steam curing chamber 10 is provided at the entrance end of the tunnel 3, and the preheating Chamber 9 is a relatively low-temperature area, and the completed prefabricated concrete member and mold table combination 7 need not be left to stand for initial setting and final setting, but are directly pushed into the preheating chamber 9, which can accelerate initial setting and final setting in winter. The waste heat of the steam curing room 10 can be used to further utilize energy and save energy, and the prefabricated components can be heated up slowly through low-temperature preheating to better ensure the quality; between the steam curing room 10 and the preheating room 9, there is an automatic opening and closing Isolation door 8, the bottom of the isolatio...

Embodiment 3

[0046] refer to Figure 6-7 As shown, it is another specific embodiment of the present invention, which is basically the same as that of Embodiment 2, except that: in the steam curing chamber 10, a plurality of isolation chambers is arranged horizontally to isolate the steam curing chamber 10 into a plurality of cavities. Plate 12, one end of the isolation plate 12 is provided with mutually staggered steam channels 13, the steam channels 13 on two adjacent isolation plates 12 are mutually staggered, and the steam curing room 10 is horizontally divided into multiple chambers by the isolation plate 12 , so that the hot steam is blocked by the horizontal partition of the isolation plate 12 during the rising process, so that the steam flows along the horizontal track direction, and then rises through the steam channel 13, effectively ensuring that the temperature in the steam curing room 10 is uniform, and ensuring that the concrete components and the mold table Combo 7 quality. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com