food heating cabin

A food and heater technology, which is applied in the field of food heating cabins, can solve the problems of inability to use one-time use, waste of edible oil, and increase the risk of cancer for consumers, and achieve the effect of hygienic food heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

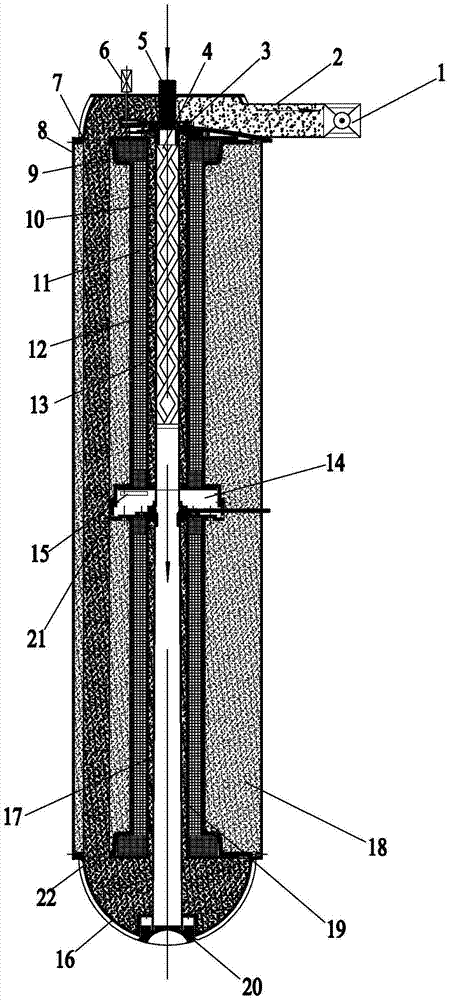

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] figure 1 Among them, including flue gas discharge regulating valve 1, inlet hood 2, oiling ring 3, rotary propulsion knife 4, material inlet 5, drive motor 6, flue gas connecting pipe 7, shell 8, electromagnetic plug group 9, inlet port Food bracket 10, heater 11, outer tube 12, inner tube 13, telescopic device 14, temperature detection element 15, outlet hood 16, outlet end food bracket 17, heat preservation medium 18, auxiliary flue 19, dust cover 20. Sewage hole 21, residual oil outlet 22, etc.

[0013] Such as figure 1 As shown, the present invention is a food heating cabin, comprising a shell 8, an outer tube 12 is arranged in the outer shell 8, an inner tube 13 is arranged in the outer tube 12, a heater 11 is set between the outer tube 12 and the inner tube 13, and the heating The quantity of the device 11 is determined accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com