Sausage roaster for microwave oven

A technology for microwave ovens and sausage grills, which is applied to the field of sausage grills, can solve the problems of high energy consumption, long cooking cycle, unsafe sanitary conditions, etc., and achieves the effects of flexible operation, avoiding uneven heating and high cooking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the drawings and embodiments.

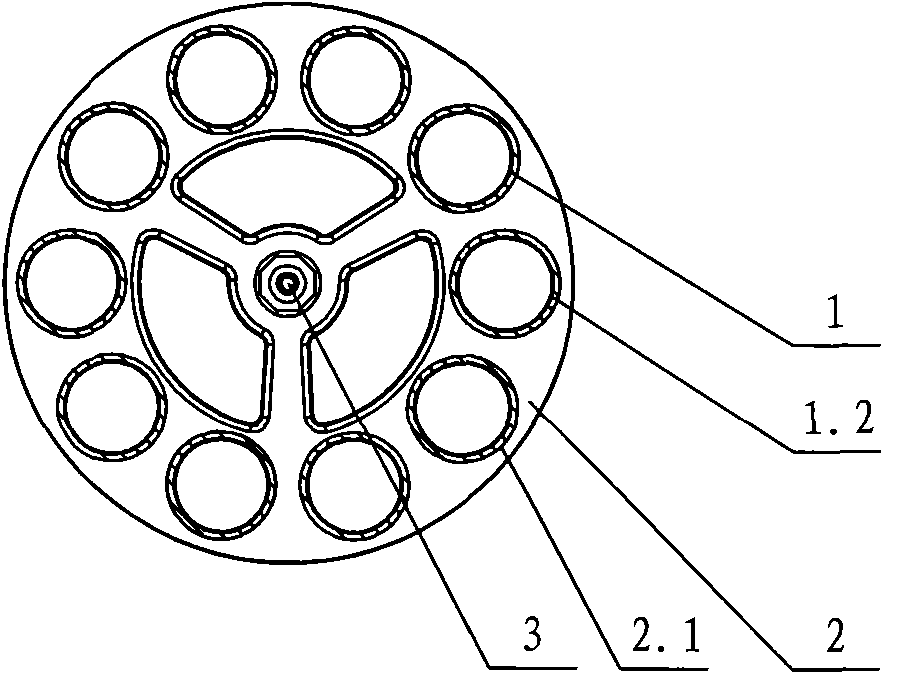

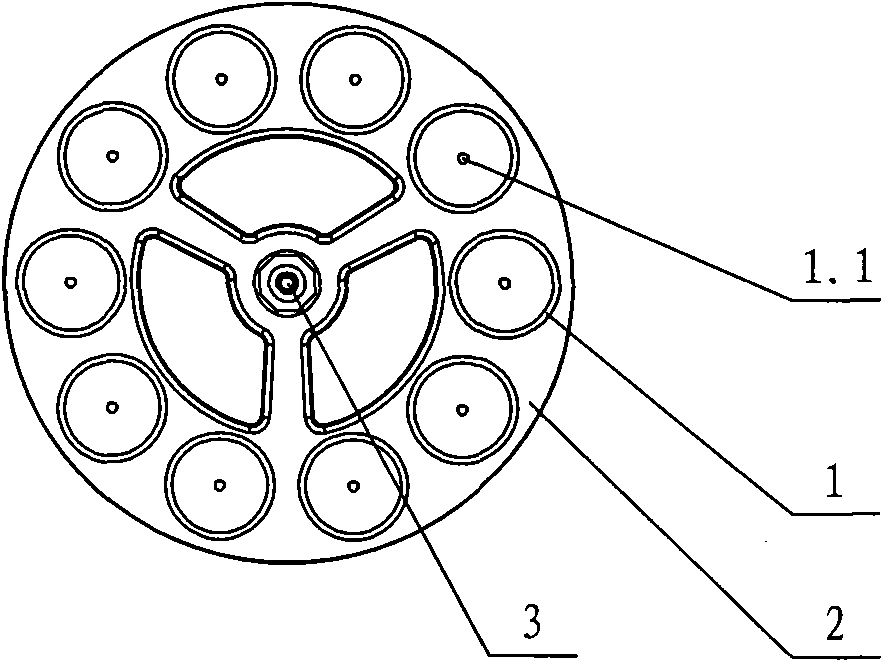

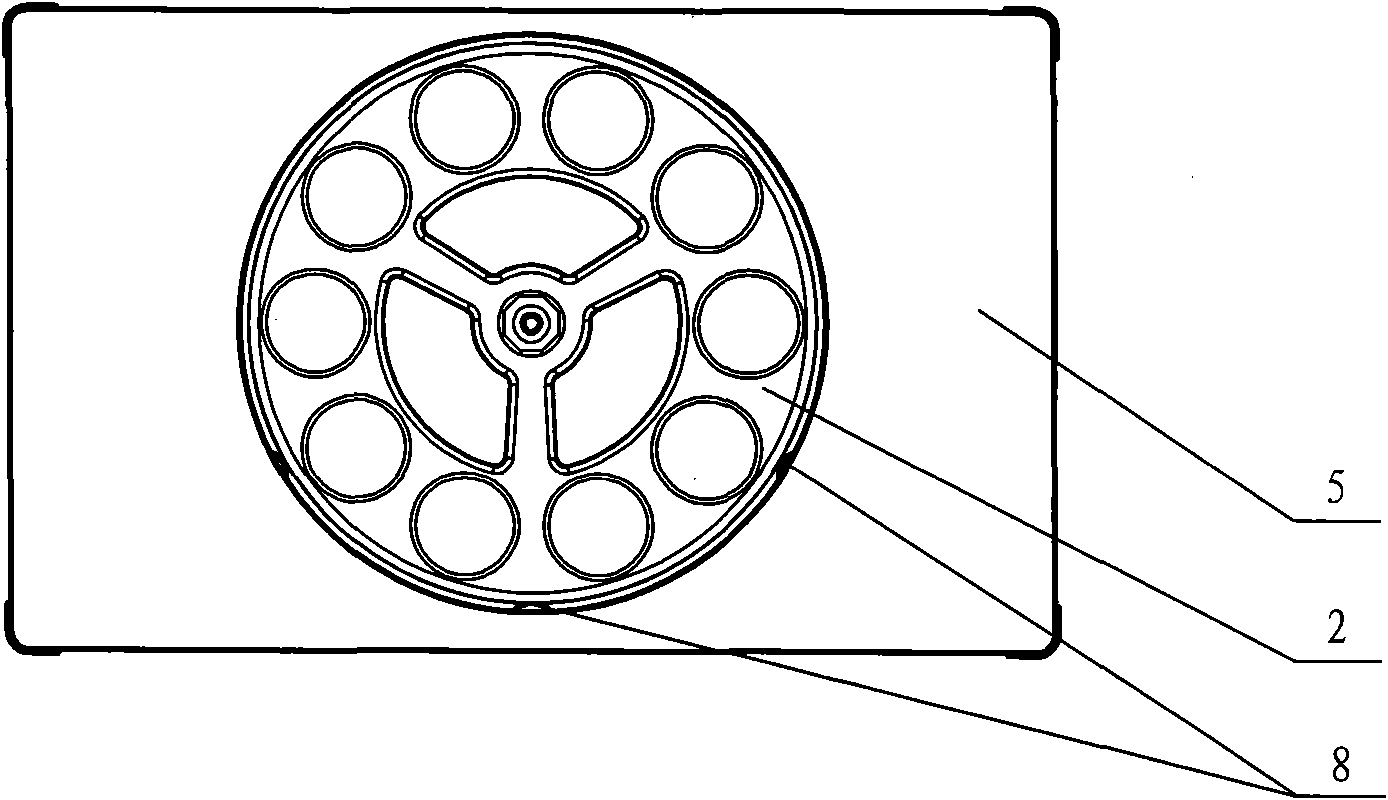

[0026] See Figure 1-Figure 7 , The sausage grill for a microwave oven includes a heating tube 1, and the outer surface of the heating tube is provided with an absorbing and heating layer 1.2. The two ends of the heating cylinder 1 are open; or, one end of the heating cylinder 1 is open and the other end is closed, and the closed end is provided with a vent hole, or one end of the heating cylinder 1 is open, and the other end is provided with a closing cover for opening and closing. The cover is provided with a vent hole. The cross section of the heating cylinder 1 is square, rectangular, pentagonal, hexagonal, heptagonal, octagonal, circular or oval. The heating cylinder 1 is made of metal material. There are more than one heating cylinders 1, and one end of the heating cylinders 1 is connected with a fixed plate 2, and the fixed plate 2 is provided with a positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com