Ring pillar for magnetic separation

A ring-column and magnetic separation technology, used in magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of uneven horizontal distribution, decrease in magnetite recovery rate, increase in metal loss, etc., to improve magnetic energy. Utilization rate, improved recovery rate, enhanced effect of magnetic field force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

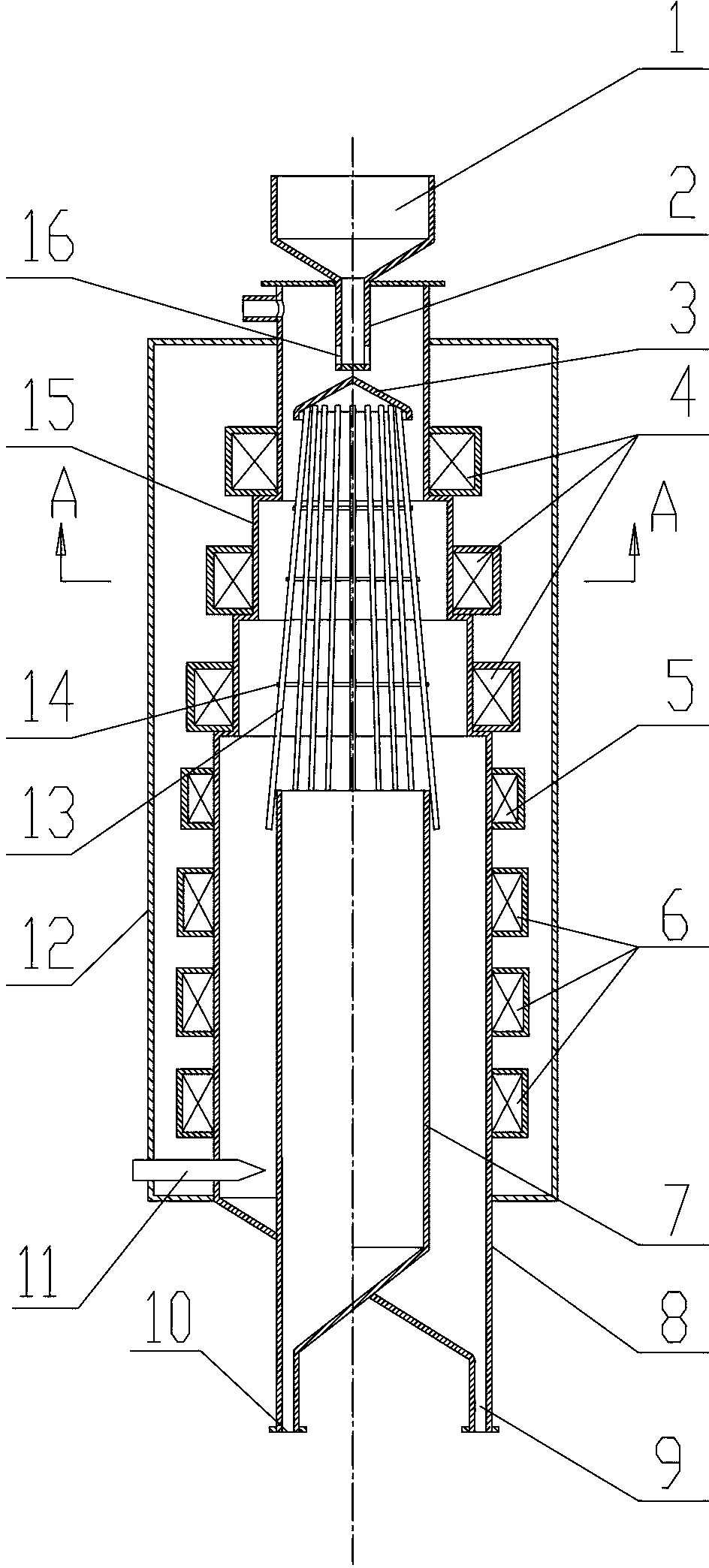

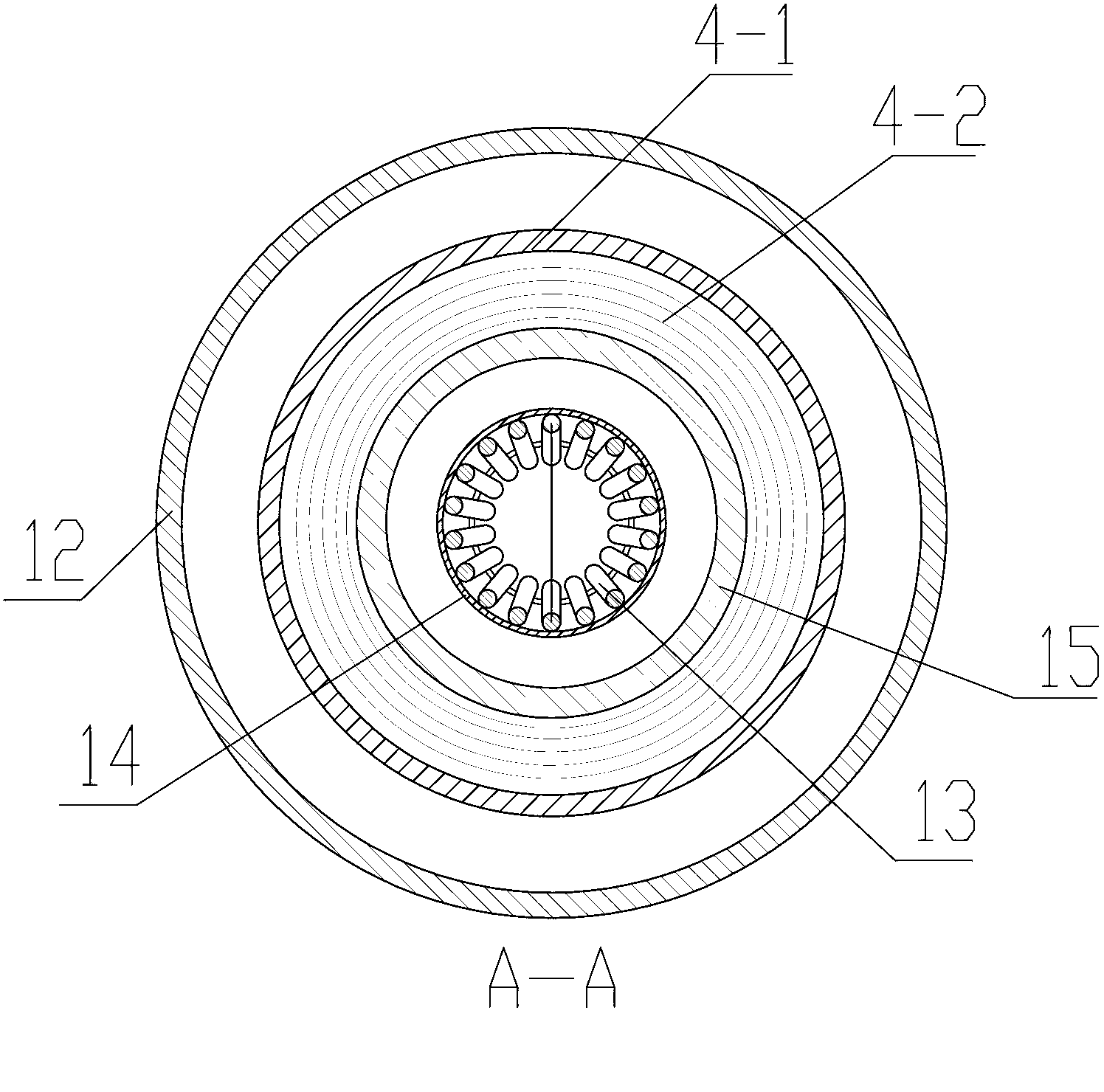

[0024] like figure 1 As shown, a magnetic separation ring column of the present invention includes an ore feeding hopper 1 with an ore feeding pipe 2, and a sorting tube connected to the lower end of the ore feeding hopper 1 is arranged on the outer surface of the sorting tube The magnetic system is set at the tailings inner tube 7 at the lower part of the sorting cylinder, the non-magnetic outer cover 12 fixedly connected with the upper and lower ends of the outer surface of the sorting cylinder and the electric control device connected with the magnetic system. device, the magnetic system is set in the non-magnetic outer cover 12, the bottom of the tailings inner pipe 7 is provided with a tailings outlet 10, the lower half of the sorting cylinder is provided with a water supply device 11, and the mine supply pipe 2 A group of ore feeding holes 16 are located in the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com